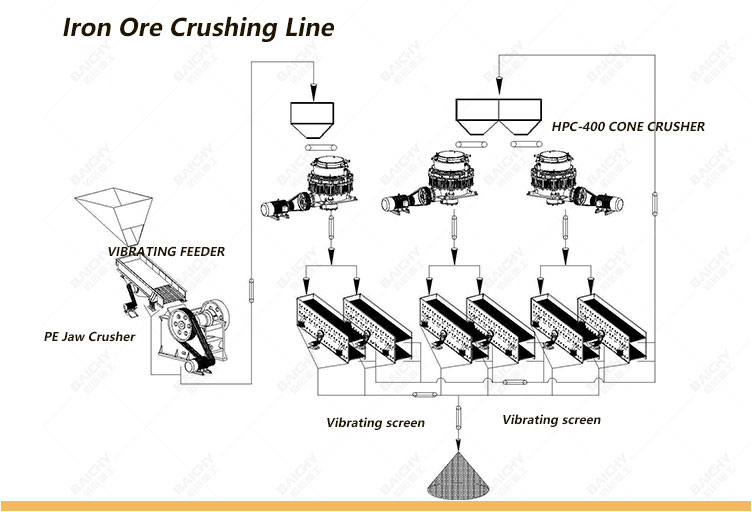

Iron Ore Crushing Line

In the fiercely competitive mining industry, an efficient and stable crushing production line is the lifeline for ensuring profits. We delve into the success story of a long-term partner to see how they utilized Bestech equipment to build a powerful and reliable iron ore crushing system, achieving long-term stable profitability.

I. Core Parameters and Configuration of the Client's Production Line

This production line is specifically designed for processing highly abrasive iron ore, with a clear objective: to efficiently process massive amounts of raw ore into fine materials suitable for the next stage of processing.

| Project | Parameters/Configuration | Description and Objectives |

| Material Processed | Iron Ore | High hardness and abrasiveness, requiring extremely high wear resistance from the equipment. |

| Feed Size | ≤ 1000mm | Directly processes large raw ore blocks from the mine. |

| Discharge Size | 0-20mm | Provides ideal feed particle size for subsequent grinding and beneficiation processes. |

| Daily Operating Time | 20 hours | High-intensity continuous operation, posing a severe test to equipment reliability. |

| Core Fixed Production Line Configuration | PE1200×1500 Jaw Crusher 1 unit | Classic jaw crusher + cone crusher hard rock combination, ensuring stable and efficient coarse and medium-fine crushing. |

| HPC-400 Cone Crusher 3 units | ||

| Mobile Crushing Configuration | YDPZ75-1142 Wheeled Mobile Crushing Station 1 unit | Used for auxiliary processing or flexible handling of raw materials from different mining areas. |

| Initial Investment Equipment | PE750×1060 Jaw Crusher 1 unit | First-time customer purchase: Excellent quality lays the foundation for trust and cooperation |

II. Detailed Production Process: The Secret to Stable and Efficient Operation

This configuration embodies a classic and efficient three-stage closed-circuit crushing process, the flow of which is as follows:

PE1200×1500 jaw crusher

1. First Stage: Coarse Crushing

◦ Equipment: PE1200×1500 jaw crusher (stationary).

◦ Task: Accepts raw ore with a particle size ≤1000mm and performs initial high-intensity crushing. Its robust structure and powerful crushing force are the foundation for the high throughput of the production line.

HPC-400 cone crushers

2. Second Stage: Medium and Fine Crushing (Core Closed-Circuit Stage):

◦ Equipment: Three HPC-400 cone crushers operating in parallel.

◦ Task: Further medium and fine crushing of the material after coarse crushing. Multiple cone crushers operating in parallel not only ensure total throughput but also provide flexibility in production scheduling. This stage typically forms a closed-circuit system with a vibrating screen to ensure that the final product particle size is consistently within 0-20mm.

3. Flexible and Mobile Unit:

◦ Equipment: YDPZ75-1142 wheeled mobile crushing station (including feeding, crushing, and screening functions).

◦ Tasks: Can supplement fixed lines, handle scrap stockpiles, independently establish temporary mining points, or be used for rapid production of specific particle size materials, greatly improving the flexibility of the entire mine operation.

III. Customer Testimonials: Choice Stems from Quality, Trust Comes from Service

Customer feedback clearly reveals the cooperation process from trial to complete trust:

“We established a cooperative relationship with Baichi because after purchasing a PE750×1060 jaw crusher, we found its quality to be excellent, so we decided to purchase mobile crushing stations from Baichi afterwards. Now the production line's profits are stable. Based on this, we have also purchased three cone crushers.”

This evaluation reveals that “equipment quality is the starting point of trust.” The excellent performance of the first jaw crusher led to orders for mobile stations and a second batch of cone crushers, proving that reliable equipment can directly translate into customer productivity and profits, thus encouraging repeat purchases.

Your company's crushing equipment is of outstanding quality, and your service is equally satisfactory. At the beginning of last year, our equipment experienced some minor problems. To resolve these issues, Baichi's technical staff stayed at our factory, spending the Spring Festival holiday with us without complaint. We were deeply moved by this.

This passage highlights that excellent service is the bond of long-term cooperation. The rapid response and dedication that transcends commercial contracts ensured the continuity of the customer's production at critical moments, upgrading the customer relationship from a buyer-seller transaction to a true partnership. Quality and service together constitute the solid guarantee of stable profits in the eyes of our customers.

IV. Summary of Success Factors: Key to Building a Profitable Production Line

1. Scientific Configuration: The fixed line combination of jaw crusher + cone crusher achieves a perfect balance of efficiency, durability, and product particle size, tailored to the characteristics of iron ore.

2. Flexible Expansion: The addition of a mobile crushing station gives the production line the mobility to cope with complex working conditions, improving overall resource utilization and response speed.

3. Quality Foundation: From PE750 to PE1200, from mobile crushers to HPC cone crushers, consistent and stable equipment quality is the core support for the production line's 20-hour/day high-intensity operation.

4. Service Support: A rapid-response, professional and dedicated technical service team minimizes the risk of unexpected downtime, ensuring a continuous return on investment.