Iron ore is the core raw material of the steel industry, and its crushing efficiency directly affects the operating cost of the production line and the quality of the final product. This article will systematically introduce the selection of iron ore crushing equipment, process design and key technical points to help you build an efficient, energy-saving and environmentally friendly crushing production line.

Iron ore crushing equipment types and selection guide

According to the crushing stage and ore characteristics, commonly used equipment includes:

1. Coarse crushing equipment (jaw crusher)

• Applicable stage: The first stage of crushing, processing large pieces of raw ore (feed size ≤ 1500mm).

• Advantages: simple structure, strong processing capacity, wear resistance, suitable for high-hardness iron ore.

• Representative models: PE series jaw crusher, HD German version jaw crusher.

2. Medium crushing equipment (cone crusher/impact crusher)

• Cone crusher: suitable for medium and high hardness ores (such as magnetite, hematite), with uniform discharge particle size, typical model HPT multi-cylinder hydraulic cone crusher.

• Impact crusher: used for medium and low hardness ores (such as limonite), with large crushing ratio and good finished product particle shape.

3. Fine crushing equipment (vertical shaft impact crusher/high pressure roller mill)

• Vertical shaft impact crusher: used for sand making (0-5mm), with both crushing and shaping functions.

• High pressure roller mill: energy saving of more than 30%, suitable for ultra-fine crushing (-2mm).

• Key to selection: select equipment combination according to ore hardness (Praeter coefficient), water content, and production capacity requirements (such as 200 tons or 1,000 tons per hour).

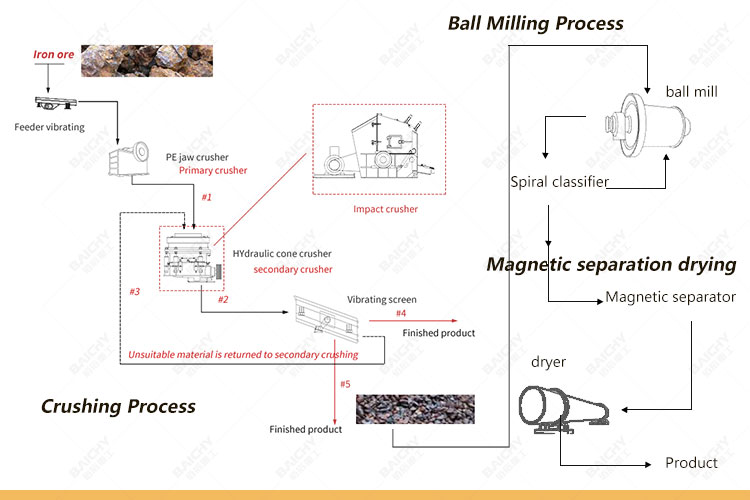

In the iron ore crushing process, three-stage closed-circuit crushing is a more modern process suitable for crushing high-hardness iron ore. This process can complete the crushing and partial dissociation of ore, thereby improving the efficiency of subsequent grinding. At the same time, the two-stage and one-close grinding is an efficient grinding process, which can grind the iron ore more fully.

In general, iron ore crushing equipment and process flow is a complex and delicate process that requires the coordinated operation of various equipment and precise process control. Only in this way can the efficient crushing and processing of iron ore be ensured, and high-quality raw materials can be provided for the subsequent production process.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.