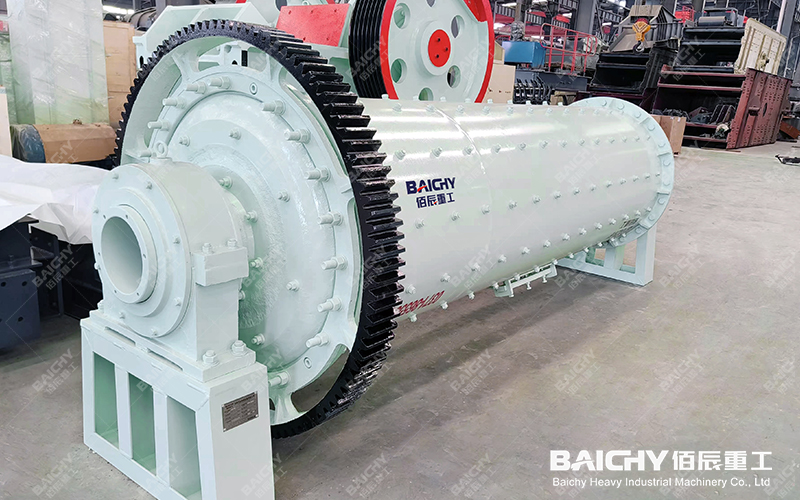

The Type of Wet Ball Mill

In industries such as mineral processing, metallurgy, chemical engineering, and power generation, material grinding is a crucial process. Wet ball mills, as one of the most mainstream and efficient pieces of equipment, achieve thorough mineral liberation through the impact and grinding of steel balls and materials in a water medium, laying the foundation for subsequent separation operations (such as flotation and magnetic separation). Compared to dry ball mills, wet ball mills are widely used in mineral processing plants due to their advantages such as higher production efficiency, lower dust pollution, less over-grinding, and better suitability for subsequent wet processes.

| Key Words | The Type of Wet Ball Mill |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Overview of Main Types of Wet Ball Mills

Although the core working principle is the same, wet ball mills can be pided into several main types based on differences in structure, discharge method, and transmission method to meet different requirements for capacity, particle size, and processes.

1. By cylinder length-to-diameter ratio: Grate type and overflow type

This is the most fundamental classification method for wet ball mills, directly determining their discharge characteristics.

• Grid-type ball mill: Equipped with a grid discharge device at the discharge end. Its advantages include forced discharge, fast discharge speed, reduced over-grinding of ore, larger processing capacity, and coarser product particle size (generally 0.2-0.3mm). Typically used for primary coarse grinding or applications requiring high product particle size uniformity.

• Overflow-type ball mill: Without grid plates, the slurry overflows due to its own weight exceeding the lower edge of the hollow shaft journal. Its structure is relatively simple, with fewer potential failure points. Its product particle size is finer (generally less than 0.2mm), but it is prone to over-grinding. Typically used for secondary fine grinding or regrinding operations.

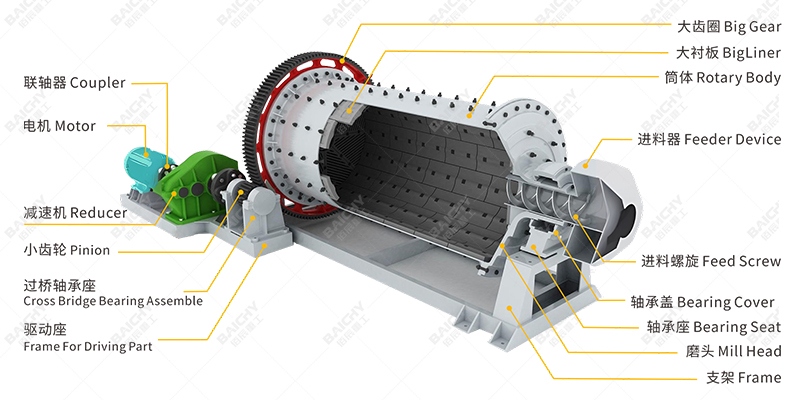

2. Classification by transmission method: Edge drive and center drive

• Edge drive ball mill: Power is transmitted via a motor to a reducer and pinion, which in turn drives a large gear ring mounted on the cylinder. This is the most traditional and widely used transmission method, with a simple structure and convenient maintenance, suitable for small and medium-sized ball mills.

• Center-driven ball mill: The motor power is directly connected to the hollow shaft of the ball mill via a reducer, driving the cylinder to rotate. This transmission method is more efficient, runs more smoothly, and occupies less space, but the structure is relatively complex. It is commonly used in large and ultra-large wet ball mills.

3. Classification by cylinder shape: Conical and tubular

• Conical ball mill: One end of the cylinder is cylindrical, and the other end is conical. This design allows steel balls of different sizes to be naturally graded along the length of the cylinder, improving grinding efficiency. However, the structure is more complex to manufacture, and it is now rarely used.

• Tubular ball mill (tube mill): The cylinder length is much larger than the diameter (length-to-diameter ratio is usually greater than 3). It is mainly used for grinding cement clinker in industries such as cement and building materials, and is less commonly used in mineral processing.

Ball mill structure diagram

Comparison and selection of different types of wet ball mills

• The advantages of grate-type ball mills are high efficiency, large output, and relatively low power consumption. They are suitable for processing ores with high hardness and large throughput requirements.

• Overflow ball mills offer advantages such as simple structure, low maintenance, and fine product particle size, making them suitable for regrinding or refining operations requiring high fineness.

• Center-driven mills, due to their high efficiency, are the preferred choice for modern large-scale ore processing plants to improve energy efficiency and reduce long-term operating costs.

Real-world application case study:

We provided solutions for a large copper mine in Southeast Asia. This plant has a daily processing capacity of 30,000 tons. In the first coarse grinding stage, we selected an MG-Φ503×6400mm large wet grate ball mill to ensure high throughput and qualified coarse grinding particle size. In the second refining and regrinding stage, we configured an MQY-Φ320×4500mm wet overflow ball mill, successfully further improving the copper concentrate grade and maximizing recovery rate. This combination fully leverages the advantages of different types of wet ball mills.

Recommended Equipment

An efficient grinding system requires not only the core ball mill but also supporting equipment working in tandem:

• Feeding equipment: such as belt conveyors and vibrating feeders, to ensure uniform and stable feeding.

• Classification equipment: such as hydrocyclones, forming a closed-loop circulation with the ball mill to control the final product particle size.

• Auxiliary equipment: such as slurry pumps (for conveying slurry), lubrication systems, and electrical control systems.

Frequently Asked Questions (FAQ)

Q1: How to decide between a grate-type or overflow-type wet ball mill?

A: It mainly depends on the required final product particle size, throughput, and process section location. A grate-type mill is chosen when a large throughput and relatively coarse product are required; an overflow-type mill is chosen when a finer product particle size is required and it is intended for regrinding. Specific selection needs to be determined through ore beneficiation tests and process calculations.

Q2: In which parts of a wet ball mill does wear mainly occur? How to maintain it?

A: The main wear parts include the inner liner, steel balls, and drive gears. Regularly checking liner wear, replenishing steel balls promptly, and maintaining a good lubrication system are crucial. Using liners made of wear-resistant materials such as high-manganese steel or chromium-molybdenum alloy steel can effectively extend their service life.

Q3: Wet ball mills have high energy consumption. What energy-saving measures are available?

A: Energy saving can be approached from multiple aspects: selecting high-efficiency energy-saving motors and center-drive systems; accurately calculating and optimizing the steel ball ratio and loading; cooperating with high-efficiency hydrocyclones to form a highly efficient closed-circuit grinding system; and adopting an automatic control system to ensure the equipment always operates under optimal load.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.