Impact Crusher VS Cone Crusher: Which Is Better?

In the mining, construction, and aggregate production industries, choosing the right crushing equipment is a key factor determining production efficiency, operating costs, and final product quality. As a manufacturer of mining crushing equipment with 20 years of experience, we are frequently asked a core question by our customers: Which is better, an impact crusher or a cone crusher?

In reality, there is no one-size-fits-all answer to this question. The definition of better depends entirely on your specific application scenario, material characteristics, capacity requirements, and investment budget. This article will provide an in-depth analysis of the principles, characteristics, applicable scenarios, advantages, and disadvantages of these two mainstream medium and fine crushing equipment, and offer professional selection advice.

Comparison of Core Working Principles

To understand the differences between the two, we must first start with their fundamental working principles.

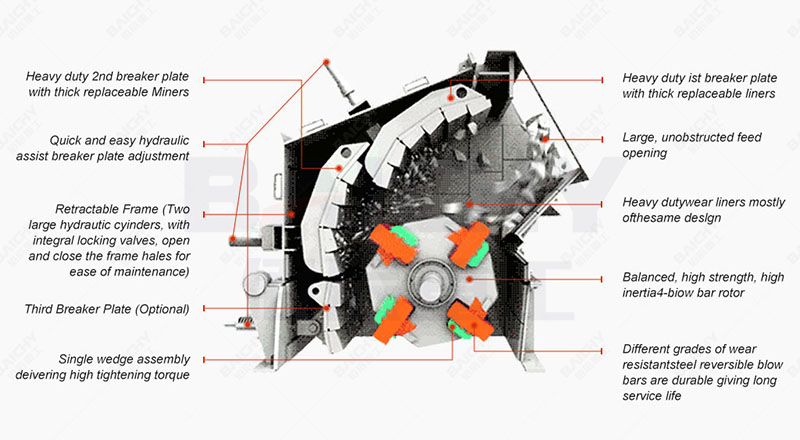

Counterattack structure diagram display

• Impact Crusher: Uses impact energy for crushing. After entering the machine, the material is violently impacted by the hammers on the high-speed rotating rotor and thrown against the impact plates inside the casing for further crushing, while also experiencing mutual impact between materials. This is a comprehensive process of impact, collision, and counter-impact.

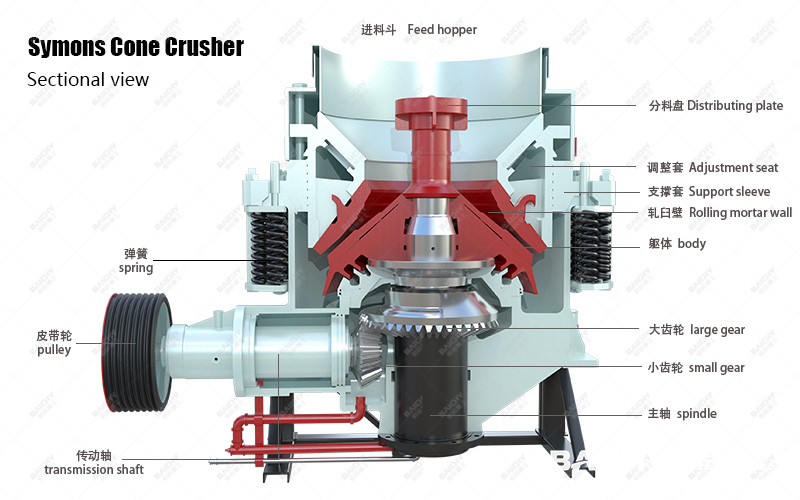

Cone fracture structure diagram

• Cone Crusher: Uses the principle of layered crushing. Driven by the eccentric sleeve, the moving cone oscillates, and within the crushing chamber formed between it and the stationary cone, the material is continuously crushed by compression, grinding, and bending. This is a steady-state, gradual, and compressive process.

This fundamental difference in principle directly leads to significant differences in their performance.

Comprehensive Performance Comparison

The following table provides a direct comparison of the two crushers from multiple dimensions:

Table 1: Impact Crusher vs. Cone Crusher - Core Characteristics Comparison

| Comparison Dimensions | Impact Crusher | Cone Crusher |

| Crushing Principle | Impact Crushing | Compressive Crushing |

| Applicable Material Hardness | Low to medium hardness, brittle materials (limestone, dolomite, coal gangue, etc.) | Medium to high hardness, highly abrasive materials (granite, basalt, quartz, etc.) |

| Product Particle Shape | Excellent, cubic, low needle-like/flaky content, suitable for high-standard aggregates | Average, more flaky, requires optimization with shaping equipment |

| Powder Content | High, easily generates stone powder during impact | |

| Hydrate/Mud Content Handling | Sensitive, easily clogged and sticky | Not sensitive, strong anti-interference ability during compressive crushing |

| Energy Consumption | Level | Relatively low,Relatively high |

| Equipment Investment Cost | Low | High |

| Consumer Parts Cost | Hammer and impact plates can be replaced quickly with low cost per replacement, but the frequency may be high. | The mantle and crushing wall have high wear resistance, high cost per replacement, but long service life. |

| Maintenance Convenience | Relatively simple structure, easy to inspect and replace wear parts. | Intricate and complex structure, higher maintenance technical requirements. |

Table 2: Selection Decision Reference Table (Based on Application Scenarios)

| Your Working Condition/Requirement Focus | Preferred Recommendation |

| Crushing medium-to-high hardness, highly abrasive rocks (e.g., granite, basalt) | Cone Crusher |

| Extremely high requirements for finished aggregate particle shape (e.g., highway pavement, ready-mixed concrete) | Impact Crusher |

| Raw material with high moisture or mud content | Cone Crusher |

| Limited investment budget, seeking higher initial cost-effectiveness | Impact Crusher |

| Seeking long-term stable operation and reducing overall maintenance downtime | Cone Crusher |

| Limited production line space, requiring high equipment flexibility | Impact Crusher (more compact structure) |

| Requires flexible adjustment of product particle size with a wide adjustment range | Impact Crusher (by adjusting rotor speed and impact plate gap) |

In-depth Analysis: Advantages and Limitations

Advantages and Challenges of Impact Crusher

Advantages:

1. Excellent Particle Shape: This is its core competitiveness, particularly suitable for producing high-quality manufactured sand and high-standard building aggregates.

2. Low Investment Threshold: Initial purchase and infrastructure costs are relatively low.

3. Simple Structure and Easy Maintenance: Daily inspections and replacement of wearing parts are relatively easy, reducing downtime.

4. Flexible Adjustment: The discharge particle size can be easily adjusted in various ways.

Challenges:

1. Limitation on Hard Materials: Not suitable for crushing high-hardness materials; otherwise, the wear of wearing parts will accelerate dramatically, leading to soaring costs.

2. Sensitive to Moisture: When the material moisture content exceeds 8%-10%, it is prone to adhesion and blockage at the impact plate and feed inlet, affecting production.

3. Dust Issues: Impact crushing generates relatively more dust, requiring a high level of environmental dust removal system.

Advantages and Challenges of Cone Crusher

Advantages:

1. Strong Crushing Capacity: A mainstay in processing medium-to-high hardness ores, offering high reliability.

2. Stable Operation and High Output: Capable of long-term, continuous, stable, and high-output operation under suitable material conditions.

3. High Wear Resistance and Controllable Overall Operating Costs: When crushing hard rock, the lifespan of its high-manganese steel mantle and crushing wall far exceeds that of the impact crusher's hammer, potentially making it more economical in the long run.

4. Unaffected by Wet Materials: The layered crushing principle allows for greater tolerance to material moisture content.

Challenges:

1. Poor Particle Shape: The product contains a high proportion of flaky stones, typically requiring a shaping machine (such as an impact crusher or vertical shaft impact crusher) for optimization.

2. High Investment: The equipment itself is expensive, with a sophisticated internal structure, demanding high foundation load-bearing capacity and installation requirements.

3. Complex Maintenance: Maintenance and repair require more specialized technicians and more complex processes.

Conclusion and Selection Recommendations:

Back to the initial question: Which is better?

• If your raw materials are medium- to low-hardness materials such as limestone and coal gangue, and you have strict standards for the finished product's particle shape and gradation, then an impact crusher is likely a more economical and efficient choice.

• If your raw materials are high-hardness materials such as granite, river pebbles, and basalt, and you are looking for long-term stability, high output, and low energy consumption per ton of production line, then a cone crusher will be a more reliable and robust partner.

As a manufacturer with 20 years of industry experience, our ultimate advice is: there is no best equipment, only the most suitable configuration. In modern large-scale sand and gravel aggregate production lines, the two are often not in a competitive either/or relationship, but rather a collaborative strong alliance. A common configuration is to use a cone crusher as the main medium crusher, ensuring stable and efficient crushing of high-hardness materials; and then use an impact crusher for fine crushing or shaping, perfectly optimizing the particle shape of the final product. This combination fully leverages the advantages of each component, achieving a win-win situation for both efficiency and quality.

When selecting equipment, please be sure to provide detailed material samples, capacity requirements, product specifications, and budget to a professional equipment supplier. Our engineers will then tailor the most scientific and cost-effective crushing solution for you.