In modern mining and aggregate processing, cone crushers are indispensable core equipment. The heart and muscles driving their efficient and safe operation are their built-in hydraulic system. It has far surpassed simple auxiliary functions, becoming a key factor determining equipment performance.

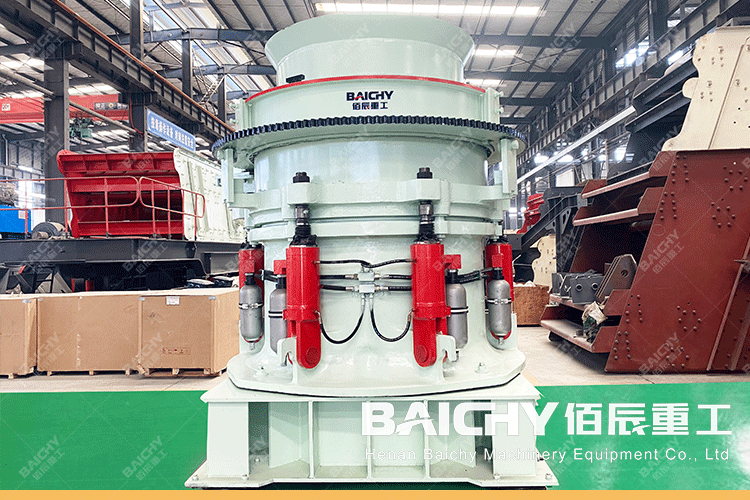

Many people's impressions of cone crushers may still be stuck in the era of bulky, cumbersome machinery. However, modern hydraulic cone crushers have undergone a complete transformation. Their built-in advanced hydraulic system is like giving the crusher an intelligent soul, achieving a leap from hard against hard to a balance of strength and flexibility. This article will delve into the multiple key roles played by the hydraulic system in cone crushers.

Hydraulic Cone Crusher PDF, Download ↓↓↓

I. Core Safety Guardian: Overload Protection and Foreign Object Removal

This is the most acclaimed function of the hydraulic system and the first line of defense for equipment safety.

• Traditional Pain Points: When uncrushable foreign objects (such as iron blocks) accidentally enter the crushing chamber, or uneven feeding causes lockdown, traditional crushers are prone to catastrophic failures such as main shaft breakage, resulting in high maintenance costs and long downtime.

• Hydraulic Solution: The hydraulic system supports the moving cone via oil cylinders. When the pressure inside the chamber exceeds a set limit, the system automatically opens like a safety valve, releasing hydraulic pressure, causing the moving cone to descend rapidly, increasing the discharge opening, and smoothly expelling foreign objects.

• Significant Advantages: The entire process is automatic and instantaneous, effectively protecting core components such as the main shaft and machine body. After unloading, the moving cone automatically resets, and the equipment quickly resumes normal production, minimizing losses from unexpected downtime.

II. Core Intelligent Control: Chamber Clearing, Discharge, and Gap Adjustment

The hydraulic system makes daily operation and maintenance easier than ever before.

• One-Button Chamber Clearing: Need to clean the material inside the crushing chamber before maintenance? No need for heavy manual labor. The operator only needs to operate one button in the control room, and the hydraulic system will drive the moving cone to descend, increasing the discharge opening and automatically discharging residual material, significantly improving maintenance efficiency and safety.

• Precise Discharge Opening Adjustment: Changing product particle size specifications is a common need. The hydraulic system precisely controls the raising and lowering of the moving cone, easily and accurately adjusting the gap between the moving and fixed cones (i.e., the discharge port). This means that particle size adjustment can be completed remotely within minutes, achieving production flexibility and automation, and meeting perse market demands.

III. Foundation for Stable Operation: Providing Crushing Force and Shock-Absorbing Lubrication

The hydraulic system is not only a regulator but also a direct provider of crushing force and a guarantee of stable operation.

• Strong Support: The hydraulic cylinder provides constant and enormous supporting force for the crushing process, which is the energy basis for crushing ore, ensuring stable and efficient crushing operations.

• Comprehensive Maintenance: The independent hydraulic station also provides forced lubrication for transmission mechanisms (such as eccentric sleeves and gears) and absorbs impact vibrations during equipment operation through accumulators, significantly extending the service life of key components such as bearings and gears.

IV. A Step Towards Intelligence: Status Monitoring and Automation

The intelligence of modern hydraulic cone crushers is based on their hydraulic systems.

• Real-time Monitoring: The system's integrated pressure and temperature sensors provide real-time feedback on equipment load and health status, providing data support for preventative maintenance.

• Intelligent Control: By integrating with a PLC (Programmable Logic Controller), advanced functions such as constant power control and automatic feeding control can be achieved, ensuring the crusher always operates at its optimal state, thereby achieving energy saving, consumption reduction, increased production, and improved quality.

In short, the deep integration of the hydraulic system has upgraded the cone crusher from a simple crushing machine into a highly efficient and intelligent production unit integrating overload protection, intelligent adjustment, and status monitoring. It is not only a guardian of safe equipment operation but also a booster for improving production efficiency and achieving automated production. When selecting a cone crusher, the advancement, reliability, and intelligence level of its hydraulic system are undoubtedly crucial considerations.

I hope this document meets your requirements. If you would like to adjust the style or add specific content, please feel free to let me know.