In the modern mining and aggregate industry, which pursues high efficiency, energy saving, and high quality, the choice of core crushing equipment directly determines the efficiency of the production line. Among numerous crushing solutions, the HPC multi-cylinder hydraulic cone crusher stands out with its revolutionary multi-cylinder hydraulic technology, becoming the preferred equipment for fine crushing of medium-hard materials. This article will guide you through an in-depth understanding of the working principle, core advantages, and why the HPC cone crusher is key to enhancing your competitiveness.

Hydraulic Cone Crusher PDF, Download ↓↓↓

I. What is an HPC Multi-Cylinder Hydraulic Cone Crusher?

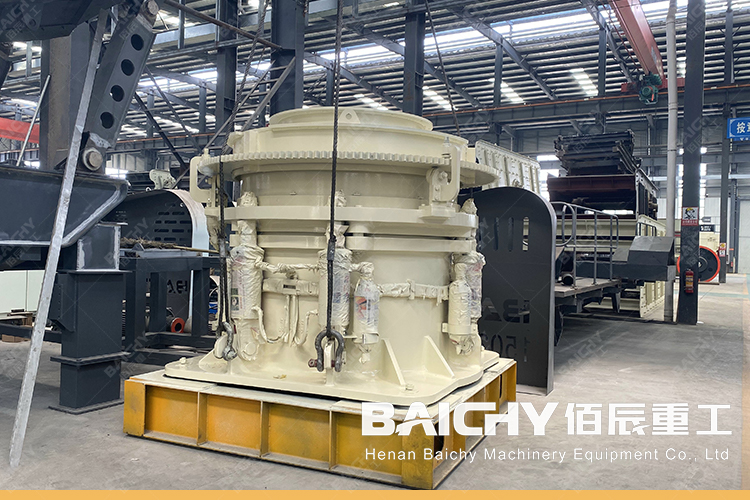

The HPC multi-cylinder hydraulic cone crusher is a new generation of high-performance crusher developed based on traditional spring cone crushers and single-cylinder hydraulic cone crushers. Its core feature lies in the use of multiple hydraulic cylinders arranged around the moving cone, achieving precise control and protection through a hydraulic system. This design not only brings greater crushing force and higher stability but also realizes an intelligent operating mode, meeting the stringent requirements of modern industry for high efficiency, intelligence, and reliability.

II. Core Technological Advantages: Why Do Top Companies Choose It?

1. High-Efficiency Crushing, Significantly Increased Output

• Optimized Chamber Design and High Swing Frequency: The HPC series features an optimized crushing chamber design and a high swing frequency, allowing materials to withstand more efficient impact and compression within the chamber. This results in a larger throughput and a significantly higher finished product output compared to traditional equipment.

• High-Power Matching: The equipment is equipped with a powerful power system, ensuring strong power even when crushing high-hardness materials, easily handling harsh conditions such as granite and basalt.

2. Superior Particle Shape, Enhanced Product Value

• Layered Crushing Principle: The equipment operates based on the layered crushing principle, where materials are compressed and ground between multiple layers of particles. The final finished product is predominantly cubic in shape, with a significantly reduced content of needle-like and flaky particles.

• High-Quality Aggregate: Excellent particle shape is crucial for high-grade concrete and high-quality sand and gravel aggregates, greatly enhancing the product's market value and competitiveness.

3. Stable Operation and Intelligent Control

• Multi-Cylinder Hydraulic System: Multiple hydraulic cylinders work together to provide powerful chamber clearing and iron overload protection functions. When uncrushable foreign objects (such as iron blocks) enter the crushing chamber, the hydraulic system automatically depressurizes, discharges the foreign objects, and then automatically resets, effectively protecting the core components of the main unit.

• High degree of automation: The discharge port size can be easily adjusted through the hydraulic and electrical control systems, achieving automated control. One person can operate it, greatly reducing labor costs and operational difficulty.

4. Simple maintenance and long service life

• Hydraulic chamber cleaning: After shutdown, the crushing chamber can be quickly cleaned via hydraulic operation, saving significant time for inspection and maintenance.

• Durable wear-resistant parts: Key components are made of high-strength wear-resistant materials, ensuring a long service life and effectively reducing equipment operating costs and downtime.

III. Main application areas of HPC hydraulic cone crushers

• Large sand and gravel aggregate plants: Provides core support for the medium and fine crushing process, and is a key piece of equipment for producing high-quality manufactured sand and gravel.

• Metal mines: Used for the medium and fine crushing of metal minerals, providing ideal feed particle size for subsequent grinding processes.

• Crushing of medium-hard materials in industries such as metallurgy, building materials, and chemicals.

IV. How to Choose the Right HPC Cone Crusher Model?

The HPC series typically includes several models (such as HPC315, HPC400, etc.). When selecting a model, the following factors should be considered:

• Feed size and output requirements: Determine the model based on your production line's designed output and maximum feed size.

• Material hardness and characteristics: Different ore hardnesses (such as granite and river pebbles) require different equipment power and wear resistance.

• Finished product particle size requirements: Clearly define your requirements for the final product particle size to ensure the optimal choice of equipment cavity design.

Our professional engineering team can provide you with free selection advice and personalized technical solutions to help you make the most informed decision.

In an increasingly competitive market environment, investing in a technologically advanced and reliable HPC multi-cylinder hydraulic cone crusher is undoubtedly a strategic choice to enhance your company's core production capabilities, reduce overall costs, and seize market opportunities. It is not just crushing equipment, but also a profit engine for achieving efficient and sustainable production.

Take action now and get a customized solution!

Are you struggling with low crushing efficiency or poor finished product particle shape? Contact us anytime to get the latest HPC multi-cylinder hydraulic cone crusher prices, detailed parameter tables, and free technical solutions tailored to your project. Let us use professional equipment to safeguard your success!