Wet High-Intensity Magnetic Separation

In the complex world of mineral separation, efficiently and accurately separating valuable target minerals from gangue has always been a core challenge in mineral processing. Wet high-intensity magnetic separation (WHIMS) technology, as a mainstay of modern mineral processing, has become the preferred solution for processing fine-grained, weakly magnetic minerals due to its powerful separation capabilities and wide adaptability.

As a manufacturer with twenty years of experience in mineral processing equipment, we will delve into the principles, advantages, and applications of this key technology to present you with professional-grade solutions.

I. Unveiling the Working Principle of Wet High-Intensity Magnetic Separation

Wet high-intensity magnetic separators generate a background magnetic field of 0.8-1.6 Tesla within the separation zone and utilize a magnetically focusing medium (such as steel wool or steel mesh) to create an extremely high magnetic field gradient. When the slurry flows through this zone, weakly magnetic mineral particles are adsorbed onto the medium due to the strong magnetic force, while non-magnetic or paramagnetic minerals pass smoothly with the slurry flow, thus achieving effective separation. The entire process takes place in the liquid phase, which not only effectively suppresses dust but also cleans the mineral surface through water flow, improving sorting accuracy.

II. Core Advantages: Why WHIMS is Irreplaceable?

Compared to traditional magnetic separation and other sorting methods, wet high-intensity magnetic separation exhibits unique value:

1. High-efficiency sorting of weakly magnetic minerals: Effectively recovers minerals that are difficult to handle with traditional magnetic separators, such as hematite, siderite, limonite, wolframite, and tantalum-niobium ore.

2. Strong capacity for handling fine-grained materials: Particularly suitable for fine and micro-fine-grained minerals down to -1mm, solving the industry problem of low recovery rates for fine-grained minerals.

3. High grade and high recovery rate: Concentrate grade and metal recovery rate are typically significantly higher than in low-intensity magnetic separation processes, greatly improving economic efficiency.

4. High degree of automation and stable operation: Modern WHIMS equipment is equipped with a PLC automatic control system, enabling fully automated control of the entire process from feeding, excitation, washing, to discharge, making operation simple and reliable.

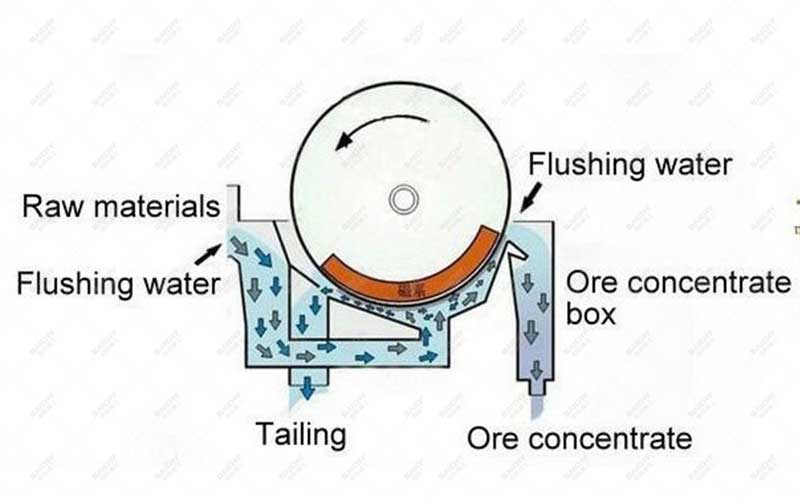

Magnetic separator structure diagram

III. Typical Application Areas Overview

Our equipment and solutions have been successfully applied to numerous projects worldwide. Below are some typical application scenarios:

| Mineral Type | Typical Grade Before Processing | Concentrate Grade After WHIMS | Key Improvement Points |

| Hematite | TFe 45%-55% | TFe > 65% | Significantly increases iron and reduces silicon, recovering fine-grained iron |

| Quartz Sand | Fe₂O₃ 0.1%-0.3% | Fe₂O₃ < 0.05% | Deep impurity removal, producing high-purity glass sand and photovoltaic sand |

| Tailure Reprocessing | Contains small amounts of valuable metals | Enriches valuable minerals | Achieves comprehensive resource utilization, turning waste into treasure |

| Potassium Feldspar | Fe₂O₃ 0.3%-0.8% | Fe₂O₃ < 0.1% | Efficient iron removal, meeting the high-end needs of ceramics and electrical porcelain |

| Rare Earth Ore | REO Mixed type | REO Preliminary enrichment | Preliminary enrichment Pre-concentration reduces the burden on subsequent flotation or leaching. |

IV. Twenty Years of Experience: Our Equipment Innovation and Process Support

Twenty years of dedicated work have taught us that an excellent magnetic separator is far more than just a collection of magnetic blocks. Our core competitiveness lies in:

• Customized Magnetic System Design: Optimizing the magnetic circuit based on the specific magnetization coefficient of different minerals ensures the best match between magnetic field strength and gradient, improving recovery rates while reducing energy consumption.

• Wear-Resistant and Corrosion-Resistant Structure: The separation tank and media box are made of special wear-resistant materials and treated with anti-corrosion agents, extending service life in harsh slurry environments and reducing maintenance costs.

• Intelligent Flushing System: Unique reverse flushing and pulse cleaning technologies ensure that the magnetic media is not easily clogged, magnetic products are thoroughly discharged, and continuous high-efficiency separation is maintained.

• Complete Process Package: We not only provide single-unit equipment, but also offer comprehensive support based on your raw ore characteristics (multi-element analysis, magnetic analysis, particle size analysis), from small-scale trials and scale-up trials to overall plant process design, ensuring project success.

As mineral resources become increasingly refined and complex, the importance of wet high-intensity magnetic separation technology will become ever more prominent. In the future, this technology will be more deeply integrated with sensors and artificial intelligence, developing towards superconducting magnetic separation and more intelligent online monitoring and adaptive control. We will continue to invest in research and development, committed to providing customers with more energy-efficient, intelligent, and efficient magnetic separation solutions, helping global mining customers maximize the value of their resources.

Choosing us is not just choosing equipment, but choosing a reliable process partner with twenty years of experience. Let us explore the infinite value hidden in your ores together.