Magnetic Separator Systems

As an industry pioneer with two decades of experience in mineral processing equipment manufacturing, we have witnessed every leap forward in magnetic separation technology, from traditional to intelligent methods. Magnetic separation systems, as powerful tools for efficient separation utilizing the magnetic differences between minerals, directly impact the final concentrate grade, metal recovery rate, and overall operational efficiency. This article will delve into the core components, technological evolution, and key selection considerations of modern magnetic separation systems.

Core Components and Technology Analysis of Magnetic Separation Systems

A complete magnetic separation system is far more than just a single magnetic separator; it is a sophisticated engineering project encompassing multiple subsystems, including feeding, separation, magnetic system, cooling, unloading, and control.

1. Magnetic System: The Heart of the System

The magnetic system is the core component responsible for generating the magnetic field required for separation. Its development has evolved from permanent magnets to electromagnets, and now to high-performance rare-earth permanent magnet materials (such as neodymium iron boron). Modern high-performance magnetic separators prioritize high magnetic field strength, large magnetic field depth, and a reasonable magnetic field gradient in their magnetic system design.

Table 1: Comparison of Mainstream Magnetic System Types

| Magnetic System Type | Main Materials | Magnetic Field Strength Range | Advantages | Typical Applications |

| Permanent Magnet System | Ferrite, Neodymium Iron Boron | Medium - Ultra-High | No excitation power supply required, low operating cost, simple structure | Roughing, scavenging, iron removal from non-metallic minerals |

| Electromagnetic System | Excitation Coil (Copper/Aluminum) | Adjustable (Wide Range) | Flexible and adjustable magnetic field strength, facilitating process optimization | Fine-grained weakly magnetic mineral separation |

| Superconducting Magnetic System | Superconducting Coil | Extremely High | Extremely high magnetic field strength, low lower limit for sorting particle size | Extremely fine-grained weakly magnetic minerals, kaolin purification |

2. Sorting Mechanisms: perse Application Scenarios

Depending on mineral particle size, magnetism, and throughput, sorting mechanisms come in various forms:

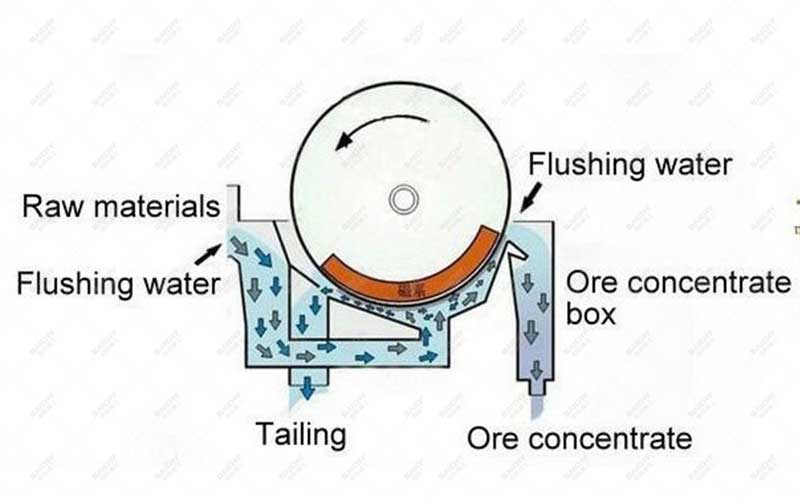

• Drum Magnetic Separator: Suitable for roughing and fine-grained coarse and medium-grained strongly magnetic minerals.

• Roller Magnetic Separator: High gradient, commonly used for fine-grained weakly magnetic mineral separation or non-metallic mineral purification.

• Vertical Ring High Gradient Magnetic Separator: High background field strength and large gradient, it is a key piece of equipment for recovering fine-grained hematite, manganese ore, and wolframite.

• Flat Plate Magnetic Separator: Primarily used to remove iron parts from belt conveyors, protecting downstream equipment.

Working-principle-of-magnetic-separator

3. Automation and Intelligent Control System

The soul of a modern magnetic separation system lies in its intelligence. Integrating PLCs and sensors, it can monitor key parameters such as magnetic field strength, bearing temperature, cooling water flow and pressure in real time, enabling remote control, fault warning, and process parameter self-optimization. This ensures stable system operation under optimal conditions, reducing reliance on manual labor and energy consumption.

Twenty Years of Experience: Customer Value-Oriented System Design

Twenty years of project experience have given us a deep understanding that there is no "one-size-fits-all" equipment, only the "most suitable" solution. Our engineering team is dedicated to providing customers with value-added services throughout the entire lifecycle.

1. Scientific Selection and Customized Design

We do not simply sell equipment; we provide system solutions. Selection is based on detailed mineral characteristic analysis (magnetism, particle size, occurrence state) and the customer's production goals.

Table 2: Key Considerations for Magnetic Separation System Selection

| Consideration Dimensions | Specific Parameters/Factors | Impact on System Design |

| Mineral Properties | Specific magnetic susceptibility, mineral composition, particle size distribution, intergrowth characteristics | Determines magnetic system type, field strength, separation structure, and equipment specifications |

| Process Requirements | Processing capacity, feed concentration, target concentrate grade, tailings magnetic content | Determines equipment specifications, process structure (e.g., single-stage/multi-stage), and flushing water configuration |

| Site Conditions | Spatial layout, power supply, water source, climate | Determines equipment layout, protection level, and cooling scheme |

| Investment and Operation | Initial investment budget, long-term operating cost target | Affects magnetic material selection, automation level, and energy-saving design |

2. Overall Efficiency Improvement and Cost Reduction

• High-efficiency recovery, increased profits: Optimized magnetic circuit design ensures a high capture rate of magnetic particles, especially critical particles, directly improving metal recovery rate.

• Energy saving and consumption reduction, green production: Adopting a high-efficiency permanent magnet system or energy-saving electromagnetic excitation scheme, combined with intelligent start-stop control, significantly reduces operating power consumption.

• Reliable and durable, easy to maintain: Key components such as magnetic blocks, bearings, and transmission mechanisms utilize high-quality materials and redundant designs. The modular structure facilitates daily maintenance and replacement of wear parts, maximizing equipment uptime.

Looking to the future: Development trends in magnetic separation technology

Looking to the future, magnetic separation technology is evolving towards greater efficiency, intelligence, and environmental friendliness. We will continue to focus on:

• Research and development of ultra-strong and stable magnetic systems: Exploring new magnetic materials and optimizing magnetic circuit simulation.

• Digital twins and intelligent optimization: Achieving real-time prediction and adaptive control of the separation process through big data and AI models.

• End-to-end system integration: Providing intelligent overall solutions for beneficiation plants, from crushing and grinding to magnetic separation and dewatering filtration.

Twenty years is the depth of experience and the starting point for innovation. We are committed to fusing every understanding of mineral characteristics and every project's accumulated craftsmanship into superior magnetic separation systems, helping global customers extract maximum value from mineral resources and achieve sustainable development.