In gypsum processing production lines, the jaw crusher is the core equipment for primary crushing, and its correct selection directly affects the efficiency, finished product quality, and long-term operating costs of the entire production system. For gypsum crushing projects with a capacity requirement of 100 tons per hour, equipment selection needs to consider not only the current output demand but also the characteristics of the gypsum material, product particle size requirements, and the compatibility with the production line. As a manufacturer with 20 years of experience in mineral processing equipment manufacturing, we will provide you with an in-depth analysis of how to scientifically select the right equipment, combining the characteristics of gypsum and practical applications.

I. Characteristics of Gypsum Material and Crushing Requirements

Gypsum (mainly composed of calcium sulfate dihydrate CaSO₄·2H₂O) is a non-metallic mineral with medium hardness and relatively high brittleness. The following points should be noted during the crushing process:

1. Moderate Hardness but Fragile: With a Mohs hardness of approximately 2 and low compressive strength, it has cleavage planes, making it prone to producing flaky or powdery materials during crushing.

2. Impact of Moisture Content: The moisture content of natural gypsum or industrial by-product gypsum affects its viscosity, potentially causing equipment blockage.

3. Product Particle Size Requirements: Crushed gypsum is primarily used in building gypsum powder and gypsum board, requiring specific specifications for both feed particle size and finished product particle size distribution.

Therefore, for gypsum crushing, jaw crushers need to possess highly efficient crushing ratio, stable discharge particle size adjustment capability, and a good anti-clogging design.

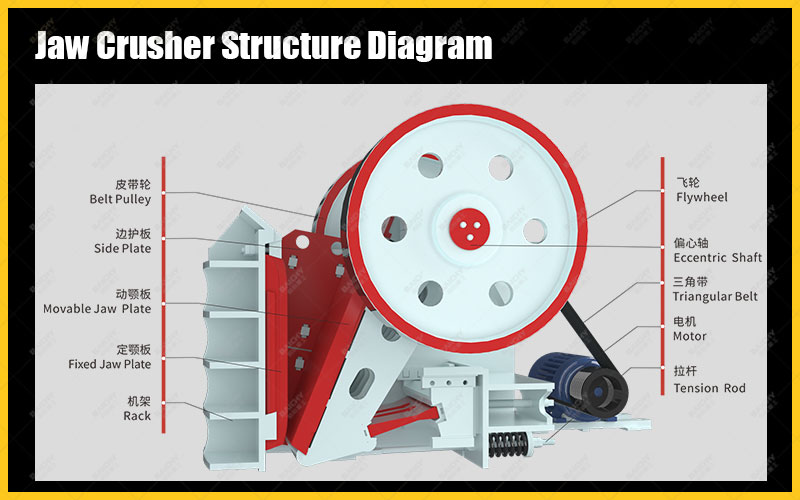

Gypsum crusher(Jaw Crusher)

II. Key Parameter Analysis of a 100-ton/hour Jaw Crusher

A capacity target of 100 tons per hour typically falls under the category of a medium-sized production line. Equipment selection cannot solely rely on the 100 tons/hour figure; factors such as feed particle size, discharge port adjustment range, and equipment power matching must be comprehensively considered.

| Key Parameters | Recommended Range/Model | Explanation and Basis |

| Feed Inlet Size | 750mm x 1060mm or above | Ensures maximum feed particle size, leaving room for production capacity. |

| Maximum Feed Particle Size | ≤630mm | Needs to be determined based on upstream feeding equipment (e.g., excavator, feeder). |

| Discharge Inlet Adjustment Range | 80-180mm | Wide adjustment range to adapt to different stages of finished product particle size requirements. |

| Main Motor Power | 110-132 kW | Provides sufficient crushing force to ensure stable operation at a load of 100t/h. |

| Eccentric Shaft Speed | ≈250 rpm | Optimizes speed to balance output and wear. |

| Estimated Weight | ≈20 tons | The weight of the equipment itself reflects the structural stability. |

Note: The above parameters are based on common configurations of the PE series deep cavity jaw crusher. Specific models need to be determined based on actual material sample testing.

III. 20 Years of Manufacturing Experience: Selection Wisdom Beyond Parameters

As a seasoned manufacturer, we understand that equipment selection is not just a matter of choosing from parameter lists, but also an engineering challenge of system matching.

Structural diagram of a jaw crusher

1. Detailed Considerations of Structure and Materials

- Moving Jaw and Fixed Jaw Plate: Considering the abrasiveness and fragility of gypsum, we recommend using jaw plates made of high-manganese steel with optimized tooth profiles. This ensures crushing efficiency while extending service life and reducing flaky products.

- Bearings and Seals: Large, heavy-duty rolling bearings are selected, equipped with a multi-layer labyrinth seal structure to effectively prevent gypsum dust intrusion, which is crucial for ensuring long-term continuous operation of the equipment.

- Discharge Port Adjustment: A modular shim adjustment system or a hydraulic adjustment device is used to make discharge port adjustment safer, more precise, and faster, adapting to different product specifications.

2. Coordination and Matching with the Production Line System

A production capacity of 100 tons per hour is not an isolated target for a single piece of equipment. It requires ensuring perfect integration between the equipment and upstream feeding, downstream conveying, and secondary crushing (if necessary).

- Feeding Equipment: We recommend equipping the jaw crusher with a heavy-duty vibrating feeder to ensure uniform, continuous, and controllable feeding, avoiding choking or no-load operation. This is a prerequisite for achieving stable production capacity.

- Discharge Conveying: Crushed gypsum must be promptly transported away via a belt conveyor with matching bandwidth and speed to prevent accumulation at the discharge port.

3. Long-Term Operating Cost (TCO) Mindset

Initial investment is only part of the cost; savvy customers focus more on Total Cost of Ownership.

- Energy Efficiency: An optimized jaw crusher design achieves a higher crushing ratio and output at the same power, directly reducing power consumption per ton.

- Lifespan and Ease of Replacement of Wear Parts: Our equipment design emphasizes symmetrical interchangeability of jaw plates to extend their lifespan and provides convenient replacement tools, significantly reducing downtime for maintenance. IV. Frequently Asked Questions (FAQ)

Q: Will a jaw crusher with a capacity of 100 tons per hour clog when processing gypsum with a slightly high moisture content?

A: The risk is low, but proactive prevention is necessary. We recommend: 1) Ensuring the jaw plate tooth design facilitates material flow; 2) Controlling the feed uniformity to avoid excessive hopper pressure; 3) Considering pre-drying or specifically designing the feeder during production line design.

Q: Besides capacity, how can the finished product particle size be guaranteed?

A: Jaw crushers primarily handle coarse crushing. To obtain a uniform final product, the maximum discharge particle size needs to be controlled by adjusting the discharge port. It typically needs to be combined with a impact crusher or vertical shaft impact crusher to form a secondary crushing system, where the latter performs shaping and fine crushing.

Q: How can I verify that the equipment can achieve a capacity of 100 tons per hour?

A: The most reliable method is to provide approximately 1-2 tons of gypsum raw material samples for a trial run with the material in the factory. We can provide this service to prospective clients, offering a visual demonstration of equipment performance and finished product results.

Choosing a 100-ton-per-hour jaw crusher for gypsum is a technical decision that combines specific needs with engineering experience. It's not just about purchasing a machine; it's about choosing a reliable, efficient, and economical starting point for your entire gypsum processing project. With 20 years of technical expertise and in-depth understanding of hundreds of projects, we offer not just single machines that meet specifications, but comprehensive solutions including professional selection advice, production line co-design, and long-term service support. We are ready to contribute to the success of your project with our professional knowledge and reliable equipment.