Crawler Impact Crusher with Capacity of 100-500tph

In the ever-changing fields of sand and gravel aggregates, construction waste recycling, and mining, the pursuit of advanced crushing equipment has never ceased: we need both astonishing processing capacity to handle large-scale production and unparalleled mobility to keep pace with the advancing work face. As a manufacturer with 20 years of experience in the mobile crushing industry, we deeply understand the importance of combining efficiency and flexibility. Today, we will delve into the core equipment that embodies these two characteristics the high-capacity crawler-mounted impact crusher and analyze how it has become the king of crushing tasks in the 100-500 tons/hour range.

| Key Words | Crawler Impact Crusher with Capacity of 100-500tph |

|---|---|

| Product Model | Crawler Impact Crusher |

| Feed Size | 0-800mm |

| Motor Power | 100-500kw |

| Capacity | 100-500 t/h |

| Core Equipment | CI Impact Crusher |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Core Advantages: What Defines High-Performance Mobile Crushing?

The crawler-mounted impact crusher is not simply a vehicle-mounted mobile unit; it is a technological product that deeply integrates a mature impact crusher with a fully hydraulic-driven crawler chassis. Its core advantages lie in:

• Exceptional Mobility and Rapid Relocation: Without the need for a tractor, the equipment can move freely within the plant or between different construction sites using its own power, and even be remotely controlled, perfectly adapting to complex and rugged terrain. This saves significant time and transportation costs for projects requiring frequent relocation.

• Excellent Finished Product Particle Shape: The impact crusher uses the principle of impact crushing, where materials are repeatedly impacted and crushed between the hammer and the impact plate. The resulting aggregate particles are cubic in shape, with excellent particle shape and low needle-like and flaky content, making them particularly suitable for high-grade concrete aggregates and asphalt mixtures.

• Wide Material Adaptability: From medium-hardness materials such as limestone and bluestone to recycled resources such as construction waste bricks, tiles, and concrete, this equipment can effectively process them. By adjusting the gap between the impact plate and the hammer, the output particle size can be flexibly controlled.

• Integrated Design and Rapid Commissioning: The equipment integrates feeding, crushing, screening, and conveying. Upon arrival at the site, it requires almost no complex foundation construction; it can be put into production immediately after connecting to power (or starting the diesel engine), greatly shortening the project preparation cycle.

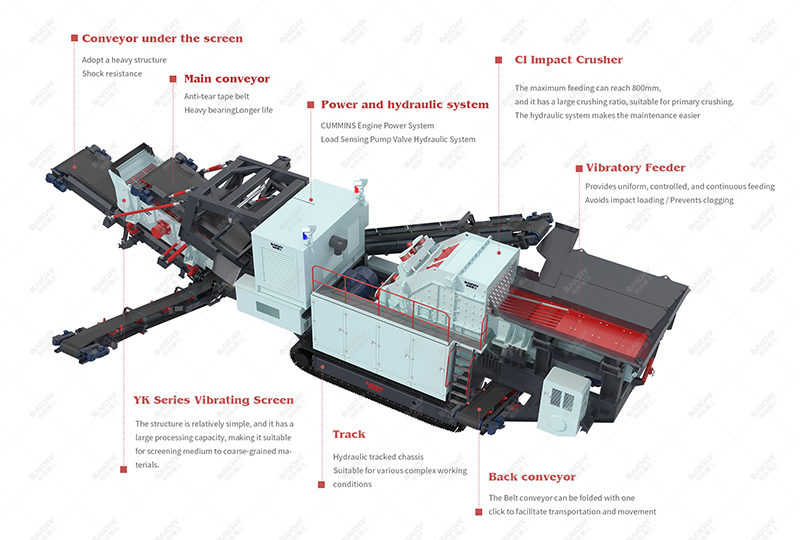

Track-mounted impact crusher structural diagram

II. Capacity Analysis: What Does 100-500 Tons/Hour Mean?

The capacity range of 100-500 tons/hour covers the needs of medium to large-scale production projects. This data is not mere talk; its realization depends on the following key design and configurations:

1. Powerful Core Impact Crusher: Equipped with a heavy-duty rotor, high-wear-resistant blow bars, and heavy-duty impact plates, ensuring stable operation and continuous high output under high impact loads.

2. Efficient Pre-screening System: Many models are equipped with a front-mounted vibrating feeder screen, which separates natural fines and soil before the material enters the crusher, while also screening out oversized materials. This increases effective processing capacity and protects the crusher.

3. Intelligent Hydraulic Control System: The integrated hydraulic system controls track movement, frame opening and closing, impact plate adjustment, and conveyor belt lifting. High degree of automation, convenient operation and maintenance, ensuring continuous and efficient operation of the production line.

4. The Essence of 20 Years of Manufacturing Experience: With twenty years of experience, we have continuously optimized structural reinforcement, center of gravity layout, and ease of maintenance. For example, easy-to-open inspection doors, centralized lubrication points, and modular wear parts are all designed to maximize equipment uptime and ensure stable production capacity.

III. Application Scenarios: Where does it shine?

• Large-scale Sand and Gravel Aggregate Production Lines: As the core of the mobile crushing section, it can be directly deployed at the quarry face, reducing truck transportation distances and significantly lowering overall costs.

• Construction Waste Recycling: Transforms waste into valuable resources on-site at urban demolition sites, producing high-quality recycled aggregates, with a capacity that perfectly matches large-scale processing needs.

• Mine Overburden Treatment: Used for processing surface overburden or low-grade ore, it is highly mobile and can move with the mining face.

• Road Construction and Maintenance: Provides on-site aggregate processing for highway and railway construction projects, ensuring particle shape and quality meet high-grade requirements.

Choosing a track-mounted impact crusher with matching capacity and reliable operation is a key decision for improving project profitability. It represents not just a piece of equipment, but a highly efficient, environmentally friendly, and flexible modern crushing production model. With 20 years of experience in the research, development, and manufacturing of mobile crushing equipment, we are committed to providing customers with solutions that not only meet nominal capacity but also create long-term value. Our equipment with a production capacity of 100-500 tons/hour is the perfect embodiment of our technological expertise and market insight.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.