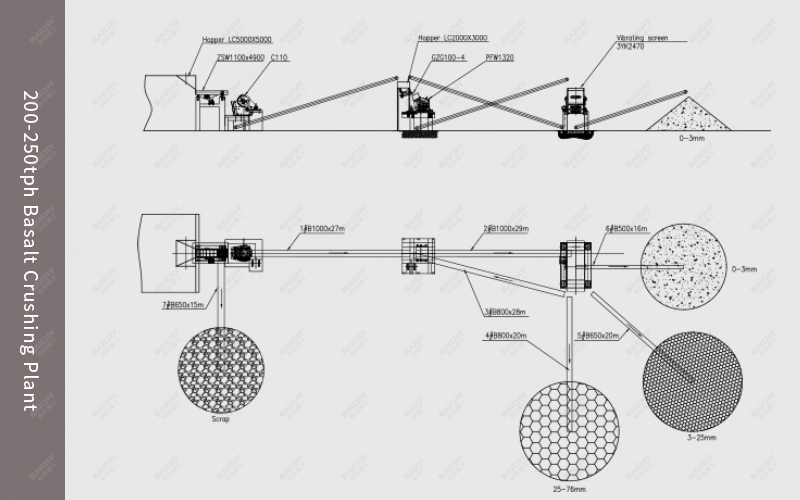

Flowchart of a 200-250tph stone crushing production line

The term "stone crusher manufacturer," though seemingly simple, accurately encapsulates a crucial link in the mining machinery industry chain. It not only refers to a production entity but also symbolizes the central hub for the transformation from raw materials to high-quality sand and gravel aggregates. In today's era of continuous infrastructure development, a reliable crusher manufacturer is the cornerstone for ensuring a stable aggregate supply and controllable costs for projects.

As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we understand that an excellent crusher manufacturer is far more than just "producing machines." It requires deep technological expertise, a profound understanding of various ore properties (such as hardness, abrasiveness, and moisture content), and the ability to provide customized solutions based on the customer's actual production needs (capacity, finished product specifications, site limitations). This article will take you deeper into understanding the value that partnering with an experienced manufacturer can bring to your stone processing project.

Stone Crushing Plant PDF,Download ↓↓↓

Four Core Advantages of Choosing a Crusher Manufacturer with 20 Years of Experience

1. Deep Technological Accumulation and Excellent Equipment Stability

Twenty years of industry experience means we have weathered countless technological iterations and market tests. Our stone crushers are designed with high-load, high-wear conditions in mind from the outset. By optimizing the crushing chamber shape and using more wear-resistant materials and manufacturing processes, our equipment has inherent advantages in stability and durability, effectively reducing unexpected downtime and ensuring long-term continuous production.

2. More Mature Solutions and Stronger Customization Capabilities

No two mines or projects are exactly alike. With over twenty years of experience handling thousands of cases, we can provide you with more mature and economical overall solutions. From simple jaw crusher coarse crushing to cone crusher medium and fine crushing, and impact crusher sand making and shaping, we can scientifically configure your production line, optimize the process flow, and avoid the investment waste caused by "equipment stacking."

3. Full Lifecycle Service, Worry-Free Support

Equipment delivery is just the beginning of our cooperation. We provide one-stop service from installation guidance, commissioning, and operation training to after-sales maintenance and spare parts supply. We have a thorough understanding of the structure of every crusher we manufacture, enabling us to quickly respond to your service needs, provide accurate spare parts and support, and greatly reduce your maintenance burden.

4. A Deep Understanding of Return on Investment (ROI)

We are not just equipment sellers, but partners in improving your production efficiency. We understand that your ultimate goal in investing is to achieve a higher return. Therefore, our solution design comprehensively considers your energy consumption, wear part lifespan, labor costs, and final product value, striving to configure the production line with the highest ROI within your budget.

Mexican C110 jaw crusher production line site

Success Story Sharing: Crushing Projects We've Collaborated With

• Case Study 1: Large-Scale Granite Quarry in Southeast Asia

◦ Challenges: High-hardness raw materials causing severe wear on equipment; requirement for high-quality aggregates in multiple sizes (0-5mm, 5-10mm, 10-20mm).

◦ Solution: A three-stage closed-loop crushing process was adopted: jaw crusher (coarse crushing) + single-cylinder hydraulic cone crusher (medium crushing) + multi-cylinder hydraulic cone crusher (fine crushing). The cone crusher is equipped with a fully automatic control system that adjusts the discharge port in real time to ensure stable finished product particle size.

• Results: Output reached 500 tons per hour; wear-resistant parts lifespan increased by 30% compared to previous equipment; finished product particle shape was excellent, fully meeting the standards for high-speed rail construction materials.

Mexican PF1320 impact crusher production line site

• Case Study 2: An Environmentally Friendly Green Sand and Gravel Aggregate Project in Central and Western China

• Challenges: Extremely high environmental protection requirements, necessitating strict control of dust and noise; relatively compact site.

• Solution: Designed a fully enclosed steel structure plant; the core production line utilizes low-noise hammer crushers and impact crushers (sand making machines). A centralized dust removal system and spray system were implemented to achieve clean production.

• Results: A garden-style factory was built; environmental ratings were achieved; the added value of aggregate products significantly increased, becoming a regional benchmark.

Recommended Stone Crusher for Different Needs

1. Primary Crushing First Choice: Jaw Crusher

• Features: Robust structure, large processing capacity, suitable for the first crushing of stones of various hardnesses. It is a "standard" core equipment for any stone crushing plant.

2. Medium and Fine Crushing Expert for Hard Rock: Cone Crusher

◦ Features: Utilizes the principle of layered crushing, suitable for high-hardness materials such as granite, basalt, and river pebbles. Low energy consumption, minimal wear, and good finished product particle shape, making it an ideal choice for high-quality aggregate production.

3. Soft Rock and Sand Making Tool: Impact Crusher

◦ Features: Utilizes the "stone-on-stone" or "stone-on-iron" principle, combining crushing and shaping functions, particularly suitable for producing manufactured sand. The finished product has a rounded particle shape and continuous gradation, meeting the requirements of high-standard construction sand.

Frequently Asked Questions (FAQ)

1: What is the approximate investment for the main equipment of a granite crushing production line with a capacity of 200 tons per hour?

A: This is a very common question. The investment amount is not fixed; it depends on the specific equipment configuration (such as whether a cone crusher and sand making machine are required), the degree of automation, and environmental protection requirements. Typically, the core equipment investment for a medium-configuration production line ranges from several million RMB. We recommend that you provide more detailed material information and finished product requirements so that we can provide you with an accurate budget plan.

2: Is your equipment more expensive compared to crusher manufacturers with only a few years of experience?

A: From the initial purchase price of a single unit, our equipment may not have an absolute advantage. However, cost should be measured from the perspective of "total life cycle cost." Our equipment's higher stability, longer wear part life, and lower failure rate can save you huge amounts of downtime losses and maintenance/replacement costs. In the long run, the overall cost is lower and the return is higher.

3: Do you provide production line design and installation services?

A: Of course. This is one of our core services as a manufacturer with 20 years of experience. We get involved from the early stages of the project, providing free site surveys, process flow design, and equipment layout planning. We provide detailed installation guidance drawings and can send engineers to the site to guide installation and commissioning, ensuring smooth production line operation.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!