Mobile crushing plant is a modular, mobile rock and construction waste processing equipment that integrates feeding, crushing, screening, and conveying functions. Its core function is its ability to directly travel to the raw material location or work site to achieve on-site crushing and preliminary processing of materials, significantly reducing material transportation costs and improving operational flexibility.

With practical experience from over 30 operational projects in the Philippines, Indonesia, Russia, Saudi Arabia, the UAE, Mexico, and other locations, Baichy mobile crushing equipment has successfully helped customers improve production efficiency by an average of over 25% and reduce overall operating costs by nearly 20% in applications such as granite and limestone mining, volcanic rock crushing, and construction waste recycling.

How does Baichy create sustainable value for local projects?

• Adaptability to complex working conditions: Stable and reliable equipment performance from humid coastal areas to mountainous mining regions;

• Resource recycling: On-site crushing and recycling of construction waste, supporting local green infrastructure development;

• Cost control advantages: Low fuel consumption, high capacity, and easy maintenance, enabling rapid return on investment;

• Localized service support: Baichy has established a three-tiered "headquarters-regional-local" service network globally, with core spare parts centers covering Southeast Asia, Central Asia, the Middle East, South America, and Africa.

Baichy mobile crushing solutions have been proven in over 150 countries and regions worldwide, covering mining, road construction, urban renewal, and solid waste resource utilization. We can provide customized equipment configurations and full-cycle operational support based on your raw material characteristics, capacity requirements, and site conditions.

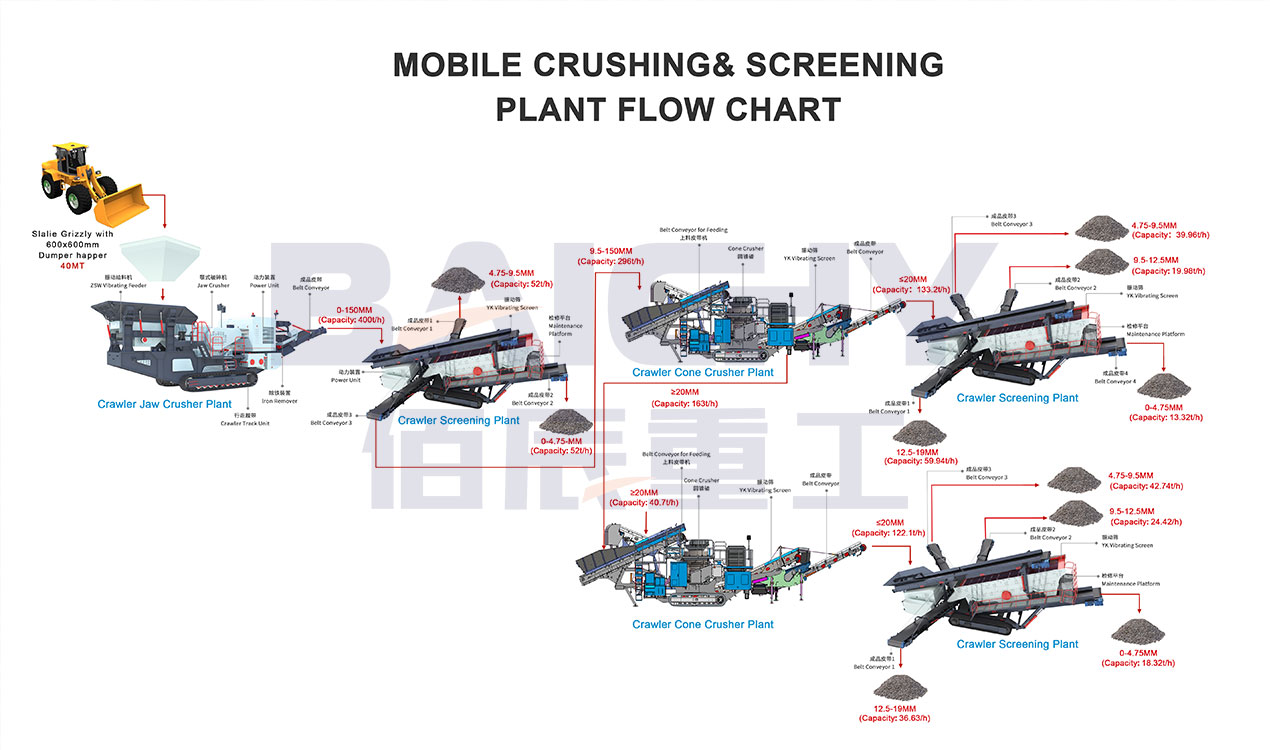

Mobile Crusher Case : Integrated Mobile Crushing Plant, Modular Mobile Crushing Plant

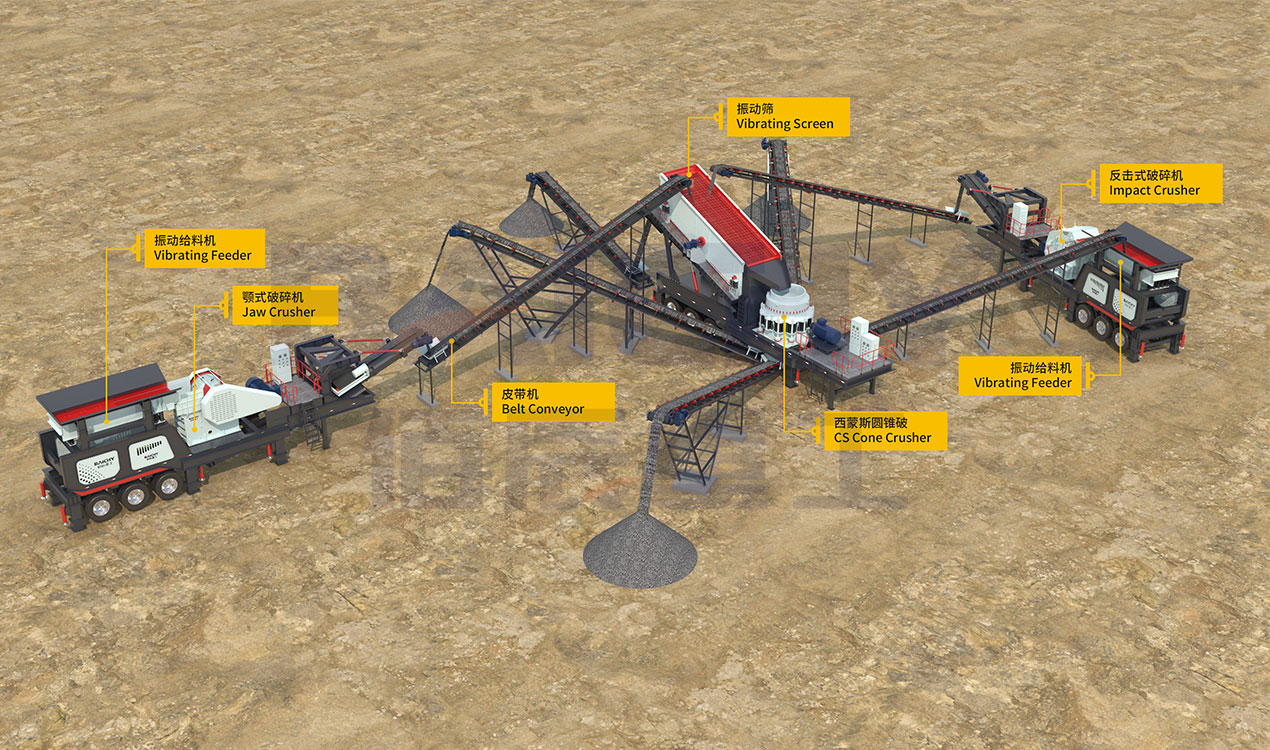

Integrated Mobile Crushing Plant: Jaw Crusher + Symons Cone Crusher

- Raw Material: Granite

- Capacity: 80-100 tph

- Location: Mexico

- Configuration: YDPZ57-75 (Coarse Crushing: PE500x750 Jaw Crusher; Medium and Fine Crushing: CS75 Symons Cone Crusher)

- Project: Aggregate Production for Road Construction

Customer Review: "The equipment operates reliably on-site, fully meeting capacity requirements. The produced aggregates have good particle shape and reasonable gradation, effectively ensuring the quality and progress of road construction. It is a mobile crushing solution very suitable for local stone conditions and project characteristics. "

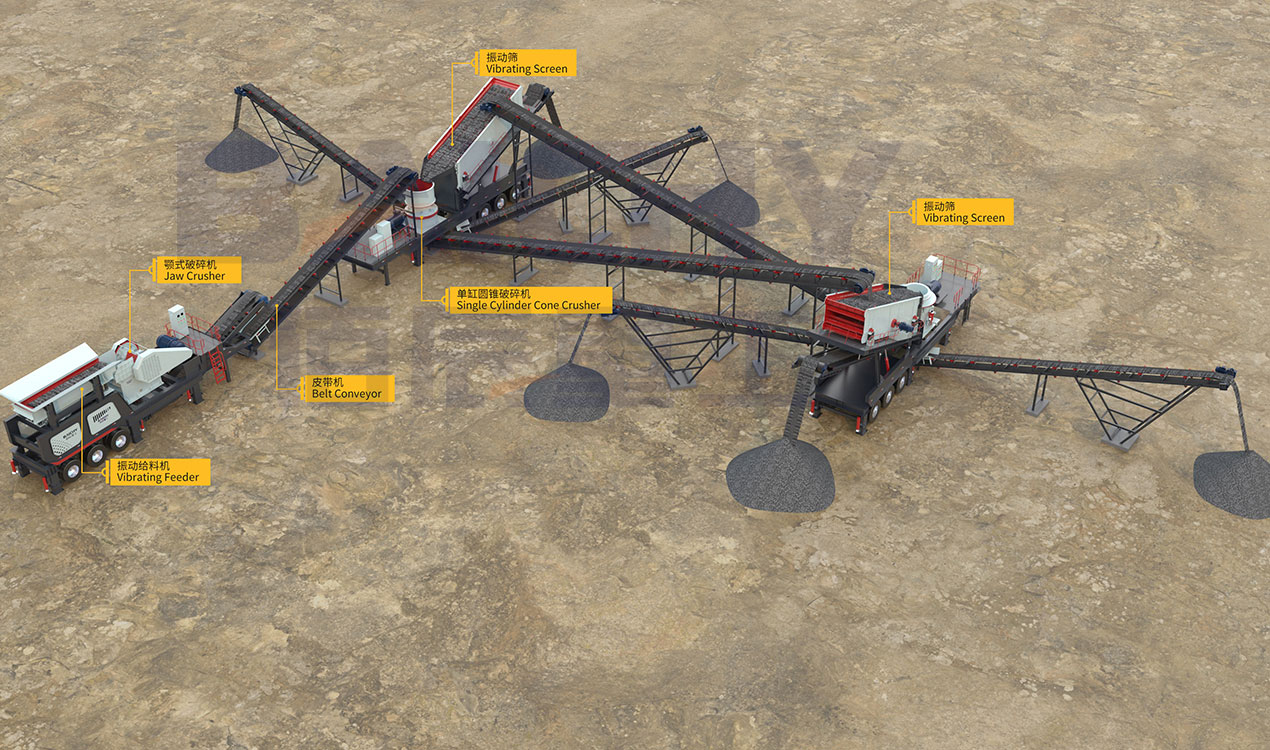

Combined Mobile Crushing Plant: Mobile Jaw Crusher + Mobile Cone Crusher

- Raw Material: Basalt (High Hardness, High Abrasiveness)

- Capacity: 200tph

- Location: China

- Configuration: YDPZ96-9638 Mobile Jaw Crusher + YDPZ160-1860 Mobile Cone Crusher.

- Project: Road Construction Aggregate Production

Ulasan pelanggan: "Despite the hardness of basalt, the two machines worked smoothly together. The cone crusher's iron ingress protection function prevented multiple unexpected shutdowns due to the entry of impurities.”

Mobile Jaw Crusher + Mobile Cone Crusher

- Raw Material: High-hardness rock

- Capacity: 200tph

- Location: Brazil

- Configuration: YDPZ106-1142 Mobile Jaw Crusher + YDPZ300-2160 Mobile Cone Crusher

- Project: Road Aggregate Production

Ulasan pelanggan: “The aggregate produced by the cone crusher has excellent particle shape, with more cubic particles and fewer needle-like and flaky particles. Our laboratory tests show that the product fully meets or even exceeds the gradation and mechanical performance requirements for road base and surface layers, and has been highly recognized by the construction team.”

The Global Standard for On-Site Processing: Stone Crushers Equipment

Our family of crushing equipment includes a full range of products, including jaw crushers, cone crushers, impact crushers, and mobile crushing plants, capable of meeting various crushing needs from mining to urban solid waste recycling. We provide intelligent crushing and screening solutions covering the entire process of primary crushing, secondary crushing, fine crushing, and sand making.

PE Series Jaw Crusher

Primary crushing station, coarse crushing unit, high-efficiency coarse crushing solution

- Capacity: 5-1200 t/h

- Feed size: ≤ 1200mm

- Output size: 25-300 mm

Main application areas/scenarios:

- Primary crushing in large mines/open-pit mines: Iron ore, copper ore, gold ore, limestone, granite, and various other metallic and non-metallic ores;

- Quarries and construction aggregate production lines: Basalt, river pebbles, construction waste, concrete blocks, etc.;

- Temporary crushing at construction sites: Temporary crushing needs for road infrastructure, water conservancy and hydropower projects, urban renewal and transformation, etc.

| Model |

Feeder Opening Size(mm) |

Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

|---|---|---|---|---|---|---|

| PE250x400 | 250x400 | 210 | 25-60 | 5-20 | 15 | 1215x1240x1210 |

| PE400x600 | 400x600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| PE600x900 | 600x900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| PE750x1060 | 750x1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| PE900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| PE1000x1200 | 1000x1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| PE1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 220 | 4590×3342×3553 |

| PE1500x1800 | 1500x1800 | 1200 | 210-360 | 520-1100 | 280 | 5100x4700x4300 |

PF Series Impact Crusher

High-efficiency secondary crushing equipment designed specifically for medium-hard materials

- Processing Capacity: 15-800 t/h

- Feed Size: ≤ 700 mm

- Motor Power: 45-355kw

Main Application Areas/Scenarios:

- Construction aggregate production lines (secondary crushing stage): Medium-hard materials such as limestone, dolomite, shale, and construction waste;

- Mining crushing systems (secondary crushing): Secondary crushing of metal ores such as iron ore, copper ore, and gold ore;

- Cement production lines (limestone crushing): Crushing of limestone before the pre-homogenization stockpile in cement plants;

- Construction waste recycling: Concrete blocks, bricks, rubble, and other construction solid waste.

| Model |

Feeder opening size(mm) |

Max feeding size(mm) |

Rotor size D*L(mm) |

Capacity (t/h) |

Power (kw) |

Overall Dimension (mm) |

|---|---|---|---|---|---|---|

| PF1007 | 450X730 | ≤250 | Φ1000X700 | 15-60 | 45 | 2330x1700x2560 |

| PF1010 | 400X1080 | ≤300 | Φ1000X1050 | 50-90 | 55 | 2330x2010x2560 |

| PF1210 | 450X1150 | ≤400 | Φ1250X1050 | 70-130 | 90 | 2640x2010x2850 |

| PFW1210 | 450X1150 | ≤400 | Φ1250X1050 | 75-140 | 90 | 2900x2000x2600 |

| PFW1214 | 480x1500 | ≤430 | Φ1250X1400 | 100-180 | 132 | 2900x2400x2600 |

| PFW1315 | 860X1520 | ≤500 | Φ1320X1500 | 130-220 | 200 | 3300x2650x2650 |

| PFW1320 | 900X2000 | ≤500 | Φ1320X2000 | 160-350 | 250 | 3350x3175x2720 |

| PFW1515 | 930x1550 | ≤600 | Φ1500X1500 | 200-400 | 280 | 3450x2750x3010 |

| PFW1520 | 930X2040 | ≤700 | Φ1512X2000 | 300-450 | 355 | 3450x3250x3010 |

| PFW1820 | 1620X2040 | ≤700 | Φ1800X2000 | 500-800 | 2 x 315 | 4400x3750x3900 |

CS Symons Cone Crusher

High-performance medium and fine crushing equipment designed for materials of medium and high hardness.

- Processing Capacity: 30-800 t/h

- Feed Size: 35-284 mm

- Motor Power: 75-400 kW

Main Application Areas/Scenarios:

- Mining medium and fine crushing operations: iron ore, copper ore, gold ore, non-ferrous metal ores, etc..

- Sand and aggregate production lines (secondary/tertiary crushing): granite, basalt, limestone, river pebbles, quartzite, etc.;

- Cement production lines: crushing before the pre-homogenization stockpile in cement plants;

- Construction waste recycling: concrete blocks, bricks, rubble, and other construction solid waste.

| Model | Cavity Type | Crushing Cone Diameter(mm) |

Adjusting Range of Discharge Opening(mm) |

Max feeding size (mm) |

Capacity (t/h) |

Motor (kw) |

Overall size (mm) |

|---|---|---|---|---|---|---|---|

| CS75 | Coarse | 900(3') | 25-38 | 150 | 59-163 | 75 | 2450×1820×2100 |

| CS75 | Medium | 900(3') | 13-38 | 85 | 45-91 | 75 | 2450×1820×2100 |

| CS75 | Fine | 900(3') | 6-22 | 35 | 27-90 | 75 | 2450×1820×2100 |

| CS110 | Coarse | 1200(4') | 15-50 | 180 | 110-250 | 110 | 2485×2050×2445 |

| CS110 | Medium | 1200(4') | 10-38 | 130 | 80-180 | 110 | 2485×2050×2445 |

| CS110 | Fine | 1200(4') | 10-31 | 90 | 63-140 | 110 | 2485×2050×2445 |

| CS160 | Coarse | 1295(4 1/4') | 19-50 | 205 | 172-349 | 132 | 2885×2320×2855 |

| CS160 | Medium | 1295(4 1/4') | 16-38 | 178 | 132-253 | 132 | 2885×2320×2855 |

| CS160 | Fine | 1295(4 1/4') | 13-31 | 115 | 109-181 | 132 | 2885×2320×2855 |

| CS220 | Coarse | 1400(4 1/2') | 30-60 | 235 | 210-530 | 220 | 3153×2358×2750 |

| CS220 | Medium | 1400(4 1/2') | 22-45 | 180 | 180-475 | 220 | 3153×2358×2750 |

| CS220 | Fine | 1400(4 1/2') | 19-40 | 100 | 130-260 | 220 | 3153×2358×2750 |

| CS250 | Coarse | 1650(5 1/2') | 30-60 | 228 | 299-635 | 250 | 3410×2620×3350 |

| CS250 | Medium | 1650(5 1/2') | 25-50 | 205 | 258-417 | 250 | 3410×2620×3350 |

| CS250 | Fine | 1650(5 1/2') | 20-45 | 178 | 181-327 | 250 | 3410×2620×3350 |

| CS315 | Coarse | 2135(7') | 31-64 | 314 | 1125-1814 | 400 | 4613×3302×4638 |

| CS315 | Medium | 2135(7') | 25-51 | 284 | 862-1424 | 400 | 4613×3302×4638 |

| CS315 | Fine | 2135(7') | 19-38 | 236 | 544-1034 | 400 | 4613×3302×4638 |

VSI Sand Making Machine

The sand making machine is the core equipment of the manufactured sand production line.

- Processing Capacity: 60-800 t/h

- Feed Size: 0-50 mm

- Motor Power: 110-520 kW

Main Application Areas/Scenarios:

- Manufactured sand production lines: river pebbles, granite, limestone, basalt, construction waste, etc.;

- Dry-mix mortar production lines: production of dry-mix mortar, special mortar, thermal insulation mortar, etc.;

- Concrete mixing plants: sand production for 5-20mm aggregates;

- Construction waste resource utilization: concrete blocks, bricks, rubble, and other construction solid waste.

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | |

|---|---|---|---|---|---|---|

| Capacity (t/h) | Cascade and Center Feeding | 120-180 | 200-260 | 300-360 | 450-520 | 490-600 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-310 | |

| Feeding Size (mm) | Soft Material | < 35 | < 40 | < 45 | < 50 | < 50 |

| Hard Material | < 30 | < 35 | < 40 | < 45 | < 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1180-1280 | |

| Power of the Double Motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | 440-520 | |

| Overall dimension L*W*H (mm) | 3700*2150*2100 | 4140*2280*2425 | 4560*2447*2278 | 5000*2700*3300 | 5100*2790*3320 | |

| Power Source | 380v:50hz | |||||

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously. | |||||

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2x0.31kw | ||||

| Safety | Double oil pumps make sure supply of oil with; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter. | |||||

| Overall Dimension L*W*H (mm) | 820x520x1270 | |||||

| Power of Oil-Box Heater | 2kw | |||||