Magnetic Separator

Introduction

In the entire process of ore processing, crushing is the first step in liberating minerals, while efficient separation is key to maximizing the value of minerals. For weakly magnetic minerals, ores with extremely fine-grained intergrowths, and the deep purification of high-purity non-metallic materials, conventional magnetic separation techniques are often insufficient. In this context, high-gradient magnetic separators demonstrate their irreplaceable core value. As a manufacturer of mobile crushing equipment for mines, we not only focus on the efficiency of crushing at the front end but also are committed to understanding advanced separation technologies at the back end. This article will delve into the high-gradient magnetic separator, a cutting-edge separation device, and explore how it has become the ultimate solution for processing difficult-to-separate minerals and achieving high-value-added product production.

Overview of High-Gradient Magnetic Separator (HGMS) Technology

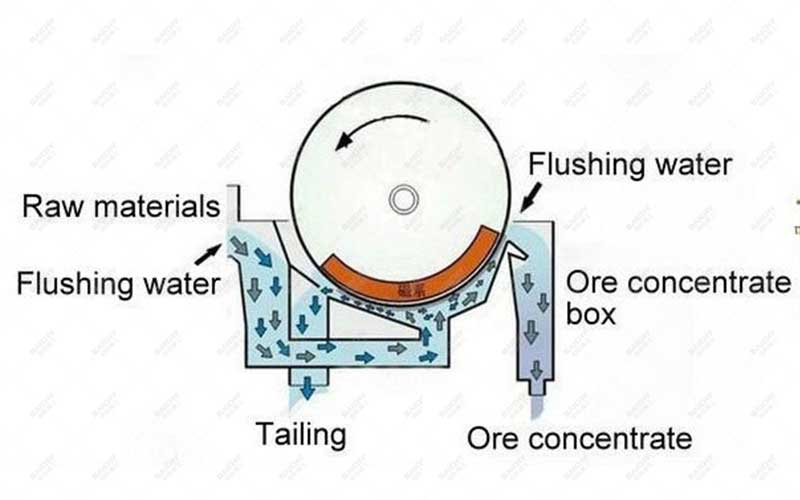

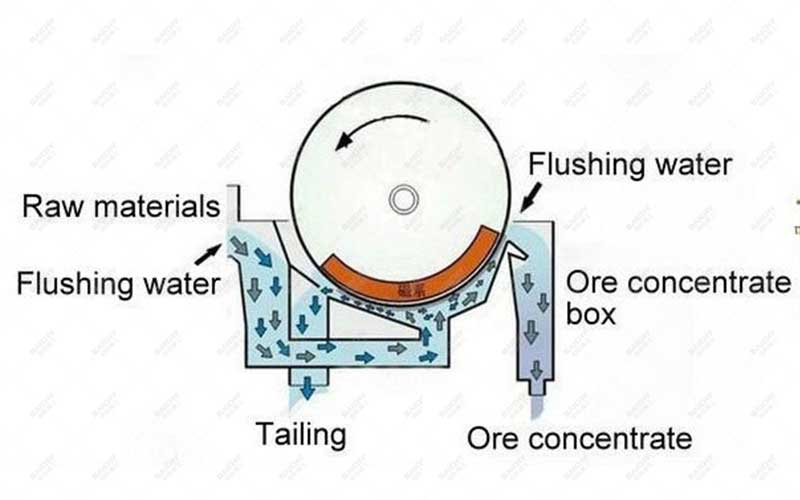

A high-gradient magnetic separator is a strong magnetic separation device capable of generating extremely high magnetic field gradients in a background magnetic field. Unlike conventional magnetic separators that primarily rely on magnetic field strength, the core of HGMS lies in its specially designed magnetic media (such as steel wool, steel mesh, steel balls, etc.). When the excitation coil is energized, these media are magnetized in a strong background magnetic field, and their tips and edges generate highly localized, extremely strong magnetic field gradients. This creates a huge magnetic attraction force on the fine-grained weakly magnetic particles (such as hematite, limonite, ilmenite, wolframite) and paramagnetic impurities in the pulp passing through the media, achieving efficient capture. HGMS is particularly suitable for the separation of materials in the -30 micron and even finer size ranges, acting as a high-precision "magnetic filter" in the field of mineral processing.

| Key Words |

HGM60 Micro Powder Mill Supplier |

| Product Name |

Magnetic Separator |

| Magnetic field intensity (oe) |

1450-1650 |

| Motor Power |

1.1-11kw |

| Capacity |

8-200t/h |

| Core Functions |

By utilizing the magnetic differences between materials, magnetic and non-magnetic substances can be separated in a non-uniform magnetic field. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Core Advantages of High-Gradient Magnetic Separators (HGMS)

In the field of fine separation, high-gradient magnetic separators, with their unique design, have solved many bottlenecks of traditional separation methods.

Powerful Capture Capability for Fine-Grained and Weakly Magnetic Materials

This is the most significant advantage of HGMS. The magnetic force generated by the extremely high magnetic field gradient is sufficient to overcome the Brownian motion and fluid resistance of fine particles, enabling the effective capture of weakly magnetic, fine-grained, and ultra-fine-grained minerals that are difficult to process with conventional magnetic separators. This makes it possible to economically recover resources that were previously difficult to recover and significantly improves the concentrate grade and recovery rate.

Achieving High-Efficiency Deep Purification of Non-Metallic Minerals

In high-value-added industries such as ceramics, electronics, and glass, the purity requirements for non-metallic raw materials such as quartz, feldspar, kaolin, and sillimanite are extremely high, especially with strict limits on the content of coloring impurities such as iron and titanium. High-gradient magnetic separation is one of the most effective and environmentally friendly physical methods for removing these paramagnetic impurities (such as Fe₂O₃, TiO₂), reducing impurity content to extremely low levels (e.g., Fe₂O₃ < 0.1% or even 0.01%), significantly increasing product value, and without chemical pollution.

High Separation Accuracy and High Degree of Automation

HGMS typically operates in a cyclical manner (feeding - magnetic adsorption - rinsing - demagnetization and discharge - rinsing), with strong process controllability. Modern HGMS has achieved a high degree of automation and programmed control, allowing for precise adjustment of magnetic field strength, media rinsing parameters, etc., based on material characteristics, ensuring a stable separation process and uniform product quality.

Application Case Studies

Case Study 1: Iron Enrichment and Silicon Reduction of Low-Grade Fine-Grained Hematite

A large hematite mine in China had ore with extremely fine particle size (mostly -20 microns) and weak magnetism, making it difficult to achieve ideal indicators using conventional magnetic separation and flotation. After introducing the SLon vertical ring pulsating high-gradient magnetic separator, its unique pulsating water flow and rod media matrix effectively separated the fine-grained hematite from the gangue. Pre-discarding tailings in the roughing stage significantly reduced the amount of ore entering the reverse flotation process, ultimately resulting in an iron concentrate grade of over 65%, with a recovery rate more than 8 percentage points higher than the old process, yielding significant economic benefits.

Case Study 2: Industrial-Scale Purification of High-Purity Quartz Sand

A company produces high-purity quartz sand for the photovoltaic and high-end electronics industries, requiring SiO₂ > 99.99% and Fe₂O₃ < 8 ppm. After the raw materials are prepared to a suitable particle size using our provided closed-circuit crushing and grinding system, the core process involves multi-stage high-gradient magnetic separation in series. Under the action of a super-strong magnetic field gradient, fine iron-titanium impurities such as goethite, tourmaline, and garnet in the raw materials are strongly adsorbed by the steel wool medium. After multi-stage HGMS (High Gradient Magnetic Separation) beneficiation, the product fully meets solar-grade and electronic-grade standards, becoming a core competitive advantage for the company in occupying the high-end market.

Systematic Collaborative Recommendation: From Crushing and Preparation to High-Precision Magnetic Separation

To fully utilize the efficiency of the high-gradient magnetic separator, sufficient liberation of the front-end materials and appropriate particle size preparation are crucial. We recommend an integrated high-purity material production line solution of "ultra-fine crushing/grinding + efficient classification + high-gradient magnetic separation":

Front-end ultra-fine preparation: Configure efficient ultra-fine crushing equipment such as vertical roller mills, stirred mills, or air jet mills to grind the raw ore or materials to the optimal particle size for HGMS (usually -100 mesh to -400 mesh, or even finer), ensuring sufficient liberation of target impurity minerals. Our closed-circuit crushing system provides stable and uniform feeding for front-end grinding.

Mid-stage precise classification: Use classification equipment such as hydrocyclones or high-frequency fine screens to strictly control the upper limit of the material particle size entering the HGMS, preventing coarse particles from blocking the gaps between the separation media and ensuring smooth operation of the separation chamber.

Back-end core high-gradient magnetic separation: Based on material characteristics (impurity type, content, and magnetism) and product targets, configure one or more high-gradient magnetic separators in series/parallel. A "one roughing, one scavenging, one cleaning" or multi-stage process can be used to gradually purify and maximize impurity removal.

Vertical Roller Mill

Frequently Asked Questions (FAQ)

Q1: What are the main differences between a high-gradient magnetic separator (HGMS) and a conventional strong magnetic separator (such as an induction roller type)?

A1: The core difference lies in the way the high magnetic field is generated and the adaptability to material particle size.

Principle: Conventional strong magnetic separators mainly generate magnetic force through high magnetic field strength; while HGMS generates extremely high magnetic field gradients by filling a uniform high background magnetic field with a magnetic medium (such as steel wool), its capture force for fine particles far exceeds that of simply high field strength. Applicable Particle Size: Conventional magnetic separators handle relatively coarse particles (usually >0.1mm); HGMS is specifically designed for fine particles (-0.1mm to -0.01mm or even finer) and is the preferred choice for processing heavily weathered ores.

Medium: Conventional machines have no special filling medium or use coarse media; HGMS relies on a dense matrix of specially designed fine steel wool or other media.

Q2: Are the operating and maintenance costs of HGMS very high?

A2: The initial investment of HGMS is usually higher than conventional magnetic separators, but its operating and maintenance costs offer overall advantages in high-end applications.

Energy Consumption: Primarily excitation energy. Electromagnetic HGMS continuously consumes power to maintain the magnetic field, but modern designs (such as superconducting HGMS) have significantly reduced maintenance energy consumption. Permanent magnet HGMS (such as some rare earth permanent magnet models) has even lower operating energy consumption.

Medium Maintenance: The magnetic separation medium (steel wool) is a consumable item and requires regular replacement or cleaning due to wear and clogging, which is one of the main maintenance costs. However, the increased product value and recovery rate usually quickly offset this cost.

Overall Benefits: For high-value minerals (such as rare earth elements, high-purity quartz) or difficult-to-process ores, the high recovery rate and improved concentrate grade provided by HGMS result in economic benefits far exceeding the increased operating costs.

Q3: Can HGMS remove all types of iron impurities from non-metallic minerals such as kaolin and quartz?

A3: HGMS is extremely effective in removing paramagnetic and ferromagnetic impurities, but its effect is limited on diamagnetic or inclusion-type iron.

Highly Effective Removal: Hematite, goethite, magnetite, ilmenite, mica, etc., existing as independent minerals.

Limited Effectiveness:

Iron existing in isomorphic form in the silicate crystal lattice (such as structural iron in feldspar).

Iron mineral inclusions encapsulated within quartz or kaolinite particles (difficult to access by physical methods).

Diamagnetic pyrite (FeS₂), which requires other methods (such as flotation). Therefore, in practical applications, HGMS is often used in combination with processes such as flotation, acid leaching, and roasting to achieve thorough iron removal.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!