Ore Processing Gold Stone Hammer Mill

In the initial stages of gold ore processing, the efficiency and cost of the crushing process directly impact the profitability of the entire production line. When dealing with hard and structurally complex gold ore, selecting a suitable primary crushing equipment is crucial.

As experts with 20 years of experience in manufacturing mining crushing equipment, we will provide a comprehensive analysis of the application of PC series hammer crushers (often referred to as small hammer crushers) in gold ore processing, revealing why they have become the opening weapon for many small and medium-sized processing plants and crushing stations.

Ore Processing Gold Stone Hammer Mill

Why is the small hammer crusher favored for gold ore processing?

Gold ore crushing has its unique characteristics: the raw ore blocks are uneven in size, may contain hard minerals such as quartz, and require controlled crushing to facilitate subsequent cyanidation or flotation recovery. Traditional jaw crushers, while robust, may produce uneven product particle sizes; while cone crushers offer good fine crushing results, their investment costs are higher.

The PC series hammer crusher strikes a balance. It uses high-speed rotating hammers to impact the material, achieving a one-step crushing effect, capable of crushing gold ore to medium or fine particle sizes (usually controllable to below 25mm) in a single pass. This makes it ideal as the second stage in a two-stage crushing process or as the core crushing equipment for small production lines.

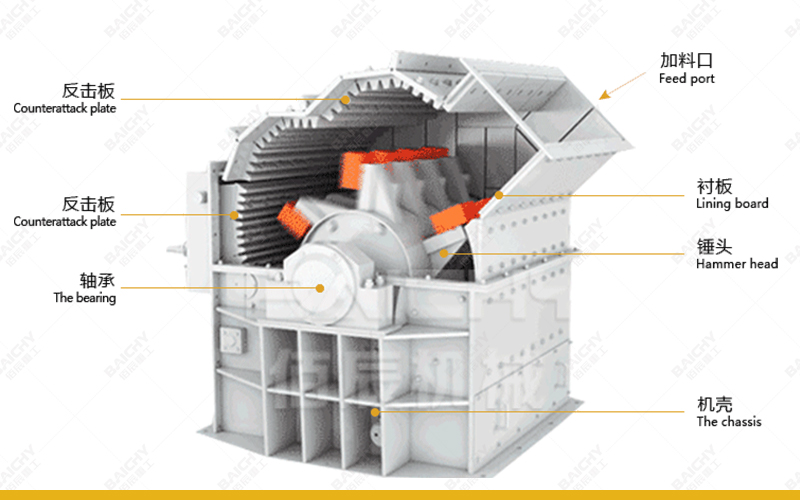

PC Series Hammer Crusher Structure Diagram

What is a PC series hammer crusher?

The PC series hammer crusher is a type of ring hammer crusher. Its core working principle is that a motor drives the rotor to rotate at high speed, and multiple hammers hinged on the rotor open under centrifugal force, violently impacting the material entering the crushing chamber. The material is rapidly crushed through impact, collision, and friction with the liner. Qualified material is discharged through the grate gaps at the bottom, achieving particle size control. This series of equipment has a compact structure and small footprint, hence it is affectionately called the small hammer crusher, making it particularly suitable for ore processing scenarios with limited space or medium processing capacity requirements. Exceptional Performance Forged by 20 Years of Expertise

With 20 years of accumulated technical expertise, we have continuously optimized our PC hammer crusher, giving it significant advantages in gold ore crushing:

1. High Crushing Ratio and Single-Stage Crushing: The unique crushing principle provides an extremely high crushing ratio, enabling single-stage crushing of gold ore, simplifying the process flow and reducing investment costs.

2. Uniform and Controllable Product Granularity: By adjusting the gap of the bottom grate bars, the output particle size can be flexibly controlled, effectively reducing over-crushing and creating favorable conditions for subsequent gold recovery.

3. Simple Structure and Convenient Maintenance: The equipment is modular in design, and core wear parts such as hammer heads and liners are made of wear-resistant materials such as high-chromium alloy, making them easy to replace and significantly reducing long-term operating maintenance costs and downtime.

4. Low Energy Consumption and High Efficiency: Compared with some traditional crushing equipment, the PC series hammer crusher consumes less energy at the same processing capacity, directly reducing the customer's operating costs.

5. Strong Adaptability: It is not only suitable for ordinary gold ore, but also has good crushing effects on gold-bearing oxide ores and altered rock-type ores with medium to low hardness.

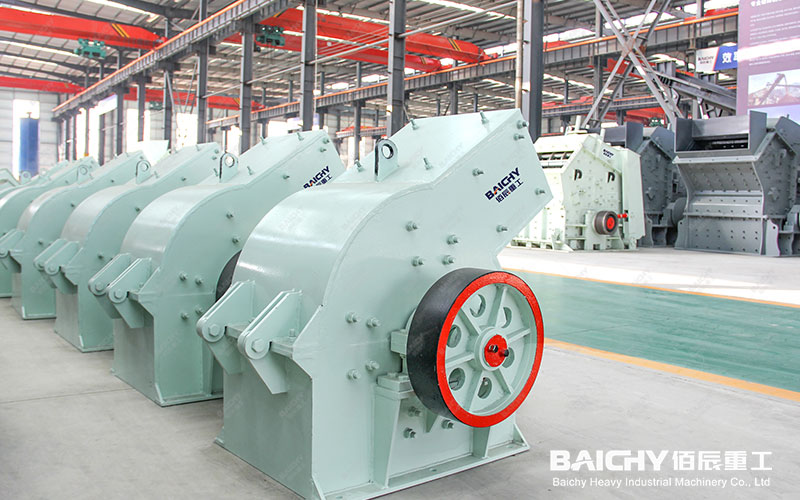

PC series hammer crusher at a customer's site.

Case Study: Application of PC Hammer Crusher in a Gold Processing Plant

We provided a solution for a small gold mine processing plant in Southwest China with a processing capacity of 200 tons/day. The mine's ore was a quartz vein type gold ore with medium to high hardness. The customer's original single-stage jaw crusher produced coarse particles (approximately 100mm), which resulted in low efficiency and high energy consumption when directly fed into the mill.

We configured a PCΦ800×600 hammer crusher as a secondary crusher. After the modification, the material from the jaw crusher was effectively crushed to less than 10mm by the hammer crusher, directly optimizing the mill feed particle size. The result was: a 20% increase in milling efficiency, a 15% decrease in overall energy consumption, and a slight increase in gold recovery due to reduced over-crushing. The customer highly praised this stable and easy-to-maintain small hammer crusher.

Related Equipment Recommendation: Building an Efficient Gold Ore Crushing Production Line

A single PC hammer crusher usually does not work in isolation. We recommend building the optimal configuration based on your specific ore properties and scale:

• Feeding Stage: A vibrating feeder (GZD series) ensures uniform and stable feeding to the hammer crusher, which is essential for maximizing its efficiency.

• Pre-crushing: For large ore lumps, we recommend using a PE series jaw crusher for primary crushing, forming an efficient two-stage crushing system with the PC hammer crusher.

• Subsequent Screening: Equipped with a circular vibrating screen (YK series) to form a closed-loop system, ensuring that the final product particle size is fully qualified and improving overall system efficiency.

Frequently Asked Questions (FAQ)

Q1: Is the PC series hammer crusher suitable for all types of gold ore?

A1: It is very suitable for gold ore with medium to low hardness and not extremely abrasive properties, such as quartz vein type and altered rock type. For extremely hard and highly abrasive primary ore, it is recommended to conduct detailed crushability tests first, or consider a jaw crusher + cone crusher solution.

Q2: What is the service life of the hammer heads? Is replacement complicated?

A2: The service life depends on the ore hardness and processing volume. Typically, under high wear conditions, a set of high-quality hammer heads can operate continuously for hundreds of hours. The replacement process is designed to be simple; it can be done by opening the machine casing, and usually takes 2-3 workers a few hours to complete.

Q3: How to control the output particle size?

A3: This is mainly achieved by adjusting the gap between the grate bars at the bottom of the crusher. Different gaps correspond to different maximum output sizes, making the operation flexible and convenient.

Q4: What are the advantages of your equipment compared to similar small hammer crushers?

A4: Our core advantage for 20 years lies in customized design and manufacturing. We not only provide standard models, but also fine-tune the rotor speed, hammer head weight and material, and grate bar structure based on the characteristics of your gold ore samples, ensuring the best match between the equipment and your ore, thus achieving higher production efficiency and lower cost per ton.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.