Big Stone Impact Crusher

In the mining and stone processing industry, crushing efficiency directly impacts production efficiency and operating costs. As a manufacturer of mining crushing equipment with 20 years of professional experience, we deeply understand the needs of global mining customers for high-performance, high-reliability crushing solutions.

Large-scale stone impact crushers are core equipment designed for crushing medium-to-high hardness materials. With their unique impact crushing principle, they demonstrate superior performance and stability in various stone crushing scenarios.

This article will provide an in-depth analysis of the equipment's advantages, applicable scenarios, and practical application cases, offering comprehensive technical reference.

| Key Words | Limestone Crusher |

|---|---|

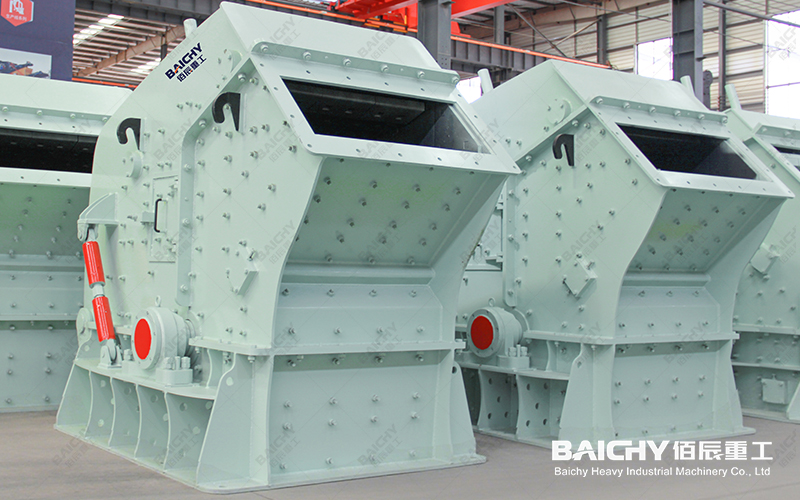

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

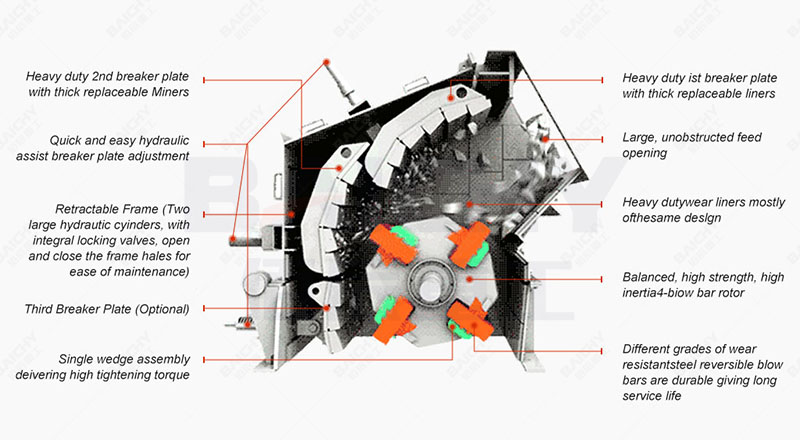

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

PF Impact Crusher Structure Diagram

Product Advantages

1. High-efficiency crushing, excellent output: Utilizing a high-speed rotating impact plate to collide with materials, crushing is achieved with a large crushing ratio and excellent finished product particle shape, significantly increasing the overall production line capacity.

2. Energy-saving and environmentally friendly, cost-controllable: Optimized impact energy transfer path reduces unit energy consumption; the enclosed structure combined with dust removal design effectively controls dust, meeting green production standards.

3. Wear-resistant and durable, easy maintenance: Key components are made of high-toughness alloy materials, offering strong resistance to impact and wear; modular design allows for quick replacement of wear parts, reducing downtime. 4. Intelligent Adaptability and Flexible Control: The rotation speed and impact gap can be adjusted according to material characteristics and output requirements, achieving multi-stage crushing in a single operation, offering strong adaptability.

5. Global Service Network: Leveraging 20 years of global project experience, we provide comprehensive technical support from installation and commissioning to lifetime maintenance, ensuring the equipment's long-term stable operation.

Application Scenarios: Large-scale stone impact crushers are widely used in:

• Primary and secondary crushing of high-hardness ores such as granite, basalt, and river pebbles.

• Production of high-quality aggregates such as building aggregates, road surface materials, and railway ballast.

• Projects across all scenarios, including mining, sand and gravel aggregate production lines, and construction waste recycling.

• Can be integrated with vibrating feeders, vibrating screens, and conveyors to form fully automated crushing and screening production lines.

PF Impact Crusher Crushing Site

Project Cases:

1. A large granite quarry in Southeast Asia: Equipped with two large impact crushers, achieving an hourly output of 800 tons, with over 90% cubic aggregate in the finished product, helping the client increase annual efficiency by more than 30%.

2. An iron ore auxiliary stone processing project in Africa: Utilizing an impact crusher to process associated basalt, the project achieved resource utilization of iron ore waste rock, opening up new profit channels for the client.

3. A highway construction material supply project in South America: The equipment has operated continuously for over 6000 hours without major repairs, and the output materials fully meet local high-standard infrastructure requirements, gaining high recognition from the client.

FAQ

Q1: What are the main differences between an impact crusher, jaw crusher, and cone crusher?

A1: An impact crusher uses a "stone-on-stone" or "stone-on-iron" principle to achieve material collision crushing, making it more suitable for medium-hard materials and producing better particle shape. Jaw crushers are suitable for primary coarse crushing, while cone crushers are suitable for high-intensity fine crushing; the three are often used in combination.

Q2: What is the typical lifespan of the equipment's wear parts?

A2: Depending on the abrasiveness of the material, the lifespan of wear parts under normal operating conditions is 500-1200 hours. We provide original equipment manufacturer (OEM) wear parts and support on-site replacement guidance.

Q3: Do you support customized configurations?

A3: Yes. We can provide customized solutions for motor power, feed size, dust removal systems, etc., based on customer needs such as site, production capacity, material characteristics, and finished product specifications.

Q4: How is after-sales service guaranteed?

A4: We have service centers in multiple regions worldwide, providing 24-hour online response, on-site technical support, regular inspections, and rapid spare parts supply to ensure the equipment operates efficiently for its entire lifespan.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.