China Jaw Crusher Manufacturers and Factory

In the global mining, construction aggregate, and infrastructure development sectors, the jaw crusher is an indispensable core piece of equipment for primary crushing. And when it comes to jaw crusher manufacturing, China has become an essential pillar in the global supply chain. As a mining crushing equipment manufacturer with 20 years of experience, we understand what Made in China represents in the crusher industry it's not just about price advantage, but a concentrated embodiment of technological accumulation, large-scale production, and in-depth customization capabilities. This article will delve into the topic of Chinese jaw crusher manufacturers and factories, providing you with a comprehensive industry insight.

Stone Crushing Plant PDF,Download ↓↓↓

Why focus on Chinese Jaw Crusher Manufacturers and Factories?

The search term Chinese jaw crusher manufacturers and factories reflects the clear demand from global buyers seeking the best combination of reliable supply chain, advanced technology, and cost-effectiveness. They are not just looking for a product, but choosing a partner who understands complex working conditions, provides long-term support, and possesses continuous innovation capabilities.

- Scale and Industrial Clusters: China possesses a complete industrial chain, from steel smelting and casting to precision machining and hydraulic and electrical control, giving manufacturers inherent advantages in quality control, production efficiency, and cost control.

- Technological Iteration and Innovation: After decades of absorbing and innovating on advanced domestic and international technologies, leading Chinese manufacturers can now provide equipment that meets global standards, and even performs better in certain application scenarios.

- Extensive Market Validation: From the tropical rainforests of Southeast Asia to the arid mining areas of Africa, and to large-scale water conservancy projects in China, Chinese-made jaw crushers have withstood the test of various extreme environments and materials, accumulating unparalleled real-world data.

Overview of the Chinese Jaw Crusher Industry

Chinese jaw crusher manufacturers are mainly located in regions with strong heavy industry foundations, such as Henan, Shanghai, Shandong, and Hunan, forming powerful industrial clusters. In terms of company types, they can be broadly pided into three categories:

1. Large-scale Comprehensive Groups: These provide complete production line solutions from primary crushing to sand making, possess strong R&D capabilities, and have significant brand influence. 2. Specialized and Deeply Experienced Manufacturers (like our company): We focus on specific fields (such as large-scale mining primary crushing and special material crushing), and with decades of technological accumulation, we enjoy a high reputation and performance advantages in niche markets.

3. Standardized Equipment Suppliers: Primarily provide economical, standardized equipment to meet the needs of small and medium-sized projects that are highly sensitive to costs.

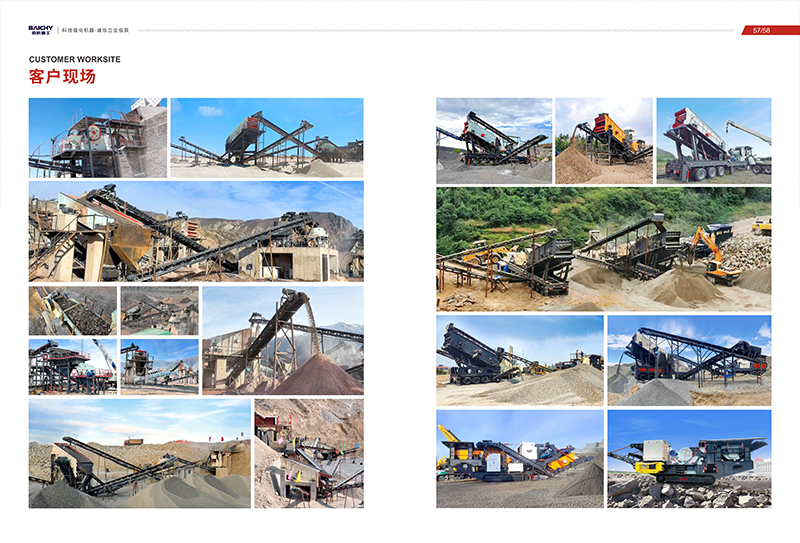

Baichy global customer site

Unique Advantages of Choosing a Professional Chinese Manufacturer

As a manufacturer with 20 years of experience, we believe that partnering with a professional Chinese partner will provide you with value that goes beyond the equipment itself:

1. Deep Customization and Adaptability to Working Conditions

We refuse a one-size-fits-all approach. Our engineering team will fine-tune the jaw plate type, eccentric shaft speed, motor power, and even the machine structure based on your specific feed size, mineral characteristics, expected capacity, and output requirements, ensuring that the equipment performs optimally on your site.

2. Unparalleled Cost-Effectiveness and Return on Investment

While ensuring that core components (such as bearings, jaw plates, and main shafts) use international first-tier brands or equivalent quality, we provide you with equipment with a lower total cost of ownership (TCO) through optimized design, efficient supply chain management, and large-scale production, significantly shortening the investment recovery period.

3. Mature Manufacturing Processes and Stable Quality

20 years of production history means we have undergone countless process improvements. From stress relief of heavy-duty welded frames to dynamic balance verification of the jaw assembly, every process has strict SOPs (Standard Operating Procedures) and quality inspection points to ensure the long-term operational stability of the equipment.

4. Service Support Throughout the Equipment Lifecycle

We are more than just sellers. From basic installation guidance and operation training to rapid spare parts supply, remote fault diagnosis, and suggestions for overhauls and upgrades, we provide support throughout the entire equipment lifecycle, making us your trustworthy long-term partner.

Success Stories: Our Jaw Crushers Around the World

- Case Study 1: Southeast Asian Granite Quarry Project

Customer Requirements: 800 tons per hour of granite primary crushing, with highly abrasive material. Our Solution: We provided a heavy-duty PE1200×1500 jaw crusher, featuring new manganese steel jaw plates and a reinforced bearing housing design. The equipment has been operating stably for over 3 years, with less annual maintenance time than planned, helping the customer exceed their production targets.

- Case Study 2: Central Asian Iron Ore Expansion Project

Customer Requirements: To add a new crushing line next to the existing production line, with limited space and a requirement for highly reliable equipment.

Our Solution: We customized a compact, deep-cavity jaw crusher and optimized the layout of the feeder and discharge conveyor. The equipment was installed quickly and seamlessly integrated with the existing system after commissioning, increasing production capacity by 35%.

Related Equipment Recommendations

Jaw crushers are usually the first stage in a crushing production line, and the efficiency of the entire line is determined by the equipment used in conjunction with it. We also provide:

- Secondary Crushing Equipment: Cone crushers, impact crushers

- Screening Equipment: Circular vibrating screens, linear vibrating screens

- Feeding and Conveying Equipment: Vibrating feeders, belt conveyors

- Mobile Crushing Plants: Wheeled and tracked mobile crushing and screening combinations

Frequently Asked Questions (FAQ)

Q1: What are the main differences between Chinese-made jaw crushers and those from European and American brands?

A: In the top-tier product lines, the performance gap is minimal. The main differences may lie in the accumulation of historical data under extreme working conditions and brand premium. However, professional Chinese manufacturers usually have a significant advantage in cost-effectiveness, customization flexibility, and service response speed. We use globally sourced key components (such as SKF bearings and Siemens motors) to ensure core reliability.

Q2: How can I ensure that the equipment I receive is of the same quality as you promised?

A: We provide three levels of assurance: 1. Factory Inspection: You are welcome to inspect and test the equipment at our factory before shipment, or you can appoint a third party to do so. 2. Process Documentation: We provide photo and video records of the main manufacturing and assembly stages. 3. Warranty Terms: We provide a clear quality guarantee period and a detailed after-sales service commitment contract.

Q3: How long does it usually take from placing an order to receiving the goods? What is the delivery time?

A: Standard models are usually in stock or can be shipped within 30-45 days. For highly customized equipment, the delivery time is typically 60-90 days, depending on the complexity. We will maintain close communication with you, provide production progress updates, and assist in planning logistics.