Stone Crusher Machine from China

In today's globalized infrastructure construction boom, efficient and reliable crushing equipment is crucial for mines, quarries, and large-scale engineering projects. As a Chinese manufacturer of mining crushing equipment with 20 years of extensive experience, we deeply understand the expectations and responsibilities associated with the label crushers from China. It represents not only geographical origin but also a symbol of quality, innovation, and value.

Stone Crushing Plant PDF,Download ↓↓↓

Why are Made in China crushers so popular?

In the past, Made in China might have been simply associated with low cost. But today, especially in the heavy machinery sector, it has evolved into a synonym for high cost-effectiveness, rapid innovation, and excellent service. Chinese crusher manufacturers, through continuous technology absorption, independent innovation, and strict quality control, are now able to provide equipment comparable to top global brands, while offering advantages in customization and responsiveness. Global customers choosing Chinese crushers are making a smarter decision for their project's return on investment (ROI).

Our Core Strengths: 20 Years of Dedicated Craftsmanship and Expertise

As a key player in the industry, we provide not just crushers, but a complete set of crushing solutions. Our advantages include:

1. A Full Range of Products and Mature Technology

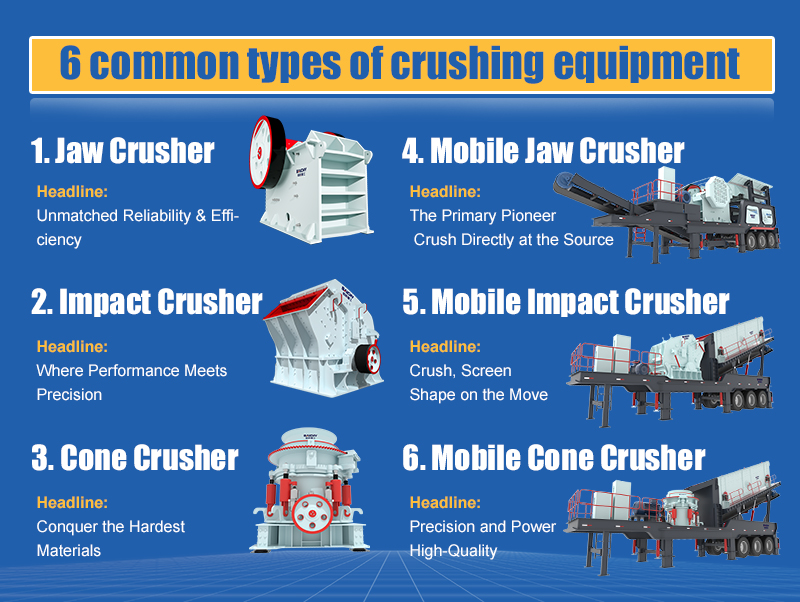

We offer a complete product line, from primary jaw crushers and secondary cone crushers to tertiary impact crushers and sand making machines. With 20 years of market testing, our equipment features optimized structure, long-lasting wear parts, and high crushing efficiency, easily handling various materials from hard granite to medium-hard limestone.

2. Excellent Cost-Effectiveness and Lower Overall Costs

While guaranteeing equivalent or even superior performance, our crushers offer significant advantages in procurement costs. Furthermore, due to our complete and efficient supply chain, spare parts are supplied quickly and at lower costs, significantly reducing customers' long-term operating and maintenance expenses.

3. Powerful Customization and Comprehensive Services

We understand the uniqueness of each mining project. From site survey, solution design, and equipment selection to installation, commissioning, operation training, and after-sales support, we provide turnkey engineering services. Equipment can be flexibly adjusted according to customer input and output specifications, capacity requirements, and site conditions. Success Stories: Our Crushers Are Operating Worldwide

Our equipment has been exported to more than 50 countries and regions worldwide. For example, in a large granite quarry in Southeast Asia, our jaw crusher + cone crusher + impact crusher three-stage crushing and screening system achieved a stable production capacity 15% higher than expected, helping the customer complete their annual production target of 3 million tons of aggregate ahead of schedule. The excellent durability of the equipment has been highly praised by the customer.

Related Equipment Recommendations

When choosing a crusher, a complete production line often requires multiple machines working together. We recommend that you also consider:

• Feeding equipment: Heavy-duty plate feeders ensure uniform and continuous feeding, which is a prerequisite for efficient operation of the production line.

• Screening equipment: Multi-layer circular vibrating screens achieve precise material classification, improving the value of finished products and the efficiency of the production line.

• Conveying equipment: Belt conveyor systems, as the arteries connecting each link, their stability and sealing are crucial.

Stone Crusher Machine

Frequently Asked Questions (FAQ)

Q1: Are crushers made in China reliable? What about their durability?

A: Absolutely reliable. We use international standard steel and key components (such as bearings and motors), and implement the ISO 9001 quality management system. The core rotors, chambers, and wear parts of our equipment are optimized in design and treated with special processes, ensuring a long service life and guaranteeing long-term stable operation under harsh working conditions.

Q2: What are your advantages compared to European brands?

A: Our core advantages lie in excellent cost-effectiveness, shorter delivery times, and more flexible customized services. With comparable technical performance, we can save you considerable initial investment. At the same time, as a manufacturer, we can provide faster and more direct response and support to your needs.

Q3: How do you provide after-sales service and spare parts support?

A: We have service centers or partners in major regions worldwide, providing localized technical support. We promise to respond to inquiries within 24 hours and provide detailed equipment drawings and operation manuals. A safety stock of key spare parts is maintained and can be quickly shipped by air or sea to minimize your downtime.

Choosing a reliable crusher is the cornerstone of project success. We sincerely invite you to learn more about our products and case studies, and let us leverage our 20 years of professional experience to help you achieve success.