Cement Hammer Crusher | Heavy-Duty Hammer Crusher

As a manufacturer of mining crushing equipment with 20 years of professional experience, we understand that in fields such as cement production, mining, and construction aggregate processing, the performance of core crushing equipment directly determines the efficiency and profitability of the production line.

Among numerous crushing equipment, the cement hammer crusher, especially the heavy-duty hammer crusher, has always occupied a crucial position due to its unique structure and superior performance.

I. What is a Cement Hammer Crusher (Heavy-Duty Hammer Crusher)?

A cement hammer crusher usually refers to a hammer crusher suitable for the medium and fine crushing of cement raw materials (such as limestone, marl, shale, etc.). The heavy-duty hammer crusher is an evolved form of the traditional hammer crusher. It features a comprehensively reinforced design of core components such as the rotor, hammers, and liners, resulting in greater processing capacity, a higher crushing ratio, and stronger resistance to impact loads. Unlike the multi-stage crushing combination of jaw crusher + impact crusher, it can often achieve one-step crushing, simplifying the process and reducing investment costs.

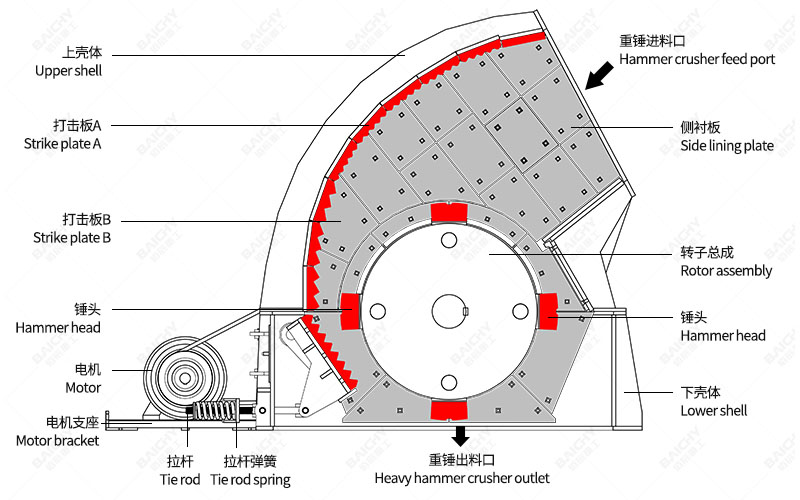

Structural diagram of a heavy-duty hammer crusher

II. Core Working Principle of the Heavy-Duty Hammer Crusher

The core working principle of the heavy-duty hammer crusher is impact crushing. The motor drives the rotor to rotate at high speed, generating enormous kinetic energy in the heavy-duty hammers hinged to it. When the material enters the machine, it is immediately crushed by the violent impact of the high-speed rotating hammers. At the same time, the accelerated material strikes the impact liner inside the machine casing and is crushed again. Qualified material smaller than the screen plate gap is discharged, while larger pieces continue to be impacted and ground by the hammers inside the machine until they reach the required particle size.

III. Why Choose Our Heavy-Duty Hammer Crusher?

With 20 years of technological accumulation and manufacturing experience, our heavy-duty hammer crushers offer the following significant advantages:

1. High Efficiency and Energy Saving, One Crusher Does the Work of Two: It has a large crushing ratio (usually 30-50), allowing large pieces of ore to be crushed to medium particle size or smaller in a single pass, greatly simplifying the process and saving on equipment and infrastructure investment.

2. Robust Structure, Extra-Long Service Life: Featuring heavy-duty hammer heads made of high-chromium alloy through integral forging, a large-sized main shaft, and a heavy-duty rotor disc, with wear-resistant alloy protective plates in key areas, the equipment is robust and durable, especially suitable for crushing high-hardness, high-silica content materials.

3. Easy Maintenance, Low Operating Costs: The machine casing adopts a hydraulic opening design, making it very convenient to replace wear parts such as hammer heads and screen plates, greatly reducing downtime and labor costs.

4. Excellent Product Particle Shape and Reasonable Particle Size Distribution: By adjusting the screen plate gap, the output particle size can be effectively controlled. The finished material is mostly cubic in shape, with low needle-like and flaky content, making it high-quality cement raw material or construction aggregate.

5. Intelligent Control, Stable Operation: It can be equipped with an advanced monitoring system (such as vibration and temperature monitoring) to achieve fault warning and ensure continuous and stable operation of the equipment.

Customer site of a heavy-duty hammer crusher

IV. Application Cases: Witnessing the Power of Heavy-Duty Hammer Crushers

We have numerous successful cases both domestically and internationally. For example, a large cement group with a 5000-ton daily production line originally used a two-stage crushing scheme. After adopting our PCZ2125 heavy-duty hammer crusher, they successfully achieved single-stage crushing of limestone, with an input particle size of ≤1200mm and an output of 95% ≤75mm, directly meeting the raw material grinding requirements. This solution saved the customer approximately 25% of the investment in the crushing section, and the hammer head service life exceeded expectations after three years of operation, earning high praise from the customer.

V. Recommended Related Equipment

Based on different material properties and capacity requirements, we recommend that you also consider the following related equipment to form the best configuration:

Feeding Equipment: Heavy-duty plate feeder to ensure uniform and stable feeding to the heavy-duty hammer crusher.

Primary Crushing: For extra-large raw materials (>1.2 meters), a jaw crusher can be used for coarse crushing.

Subsequent Screening: A vibrating screen can form a closed-loop system with the hammer crusher to precisely control the final product particle size. Dust Control: Equipped with high-efficiency bag filters to meet environmental protection requirements.

VI. Frequently Asked Questions (FAQ)

Q1: What type of material is the heavy-duty hammer crusher best suited for crushing?

A1: It is best suited for crushing brittle materials with a compressive strength of no more than 200MPa, such as limestone, bluestone, gypsum, coal, shale, etc. It is an ideal choice for the cement, building materials, and chemical industries.

Q2: What is the service life of the hammer heads? Is replacement complicated?

A2: The service life varies greatly depending on the hardness and abrasiveness of the material, typically ranging from several hundred to thousands of hours under highly abrasive conditions. Our equipment uses a hydraulic opening device, making hammer head replacement very simple and usually completed within a few hours.

Q3: How is the output particle size controlled?

A3: It is mainly controlled by adjusting the gap size of the bottom screen plate. We offer screen plates with various gap sizes to meet different product particle size requirements.

Q4: Compared with the jaw crusher + impact crusher solution, what are the advantages of the heavy-duty hammer crusher solution?

A4: The core advantages lie in a shorter process flow, smaller footprint, lower equipment investment and maintenance costs, and lower power consumption. While meeting process requirements, it can significantly improve project economics.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.