BAICHY PE600x900 Jaw Crusher | Primary Crushing Expert

I. In-Depth Topic Analysis: Why is Primary Crushing So Crucial?

In aggregate production lines for mining, quarrying, and construction waste recycling, primary crushing is the "bottleneck" of the entire process. Its performance directly determines the efficiency of subsequent secondary and tertiary crushing, screening, and other stages, as well as the quality of the final product. Choosing an efficient, stable, and durable jaw crusher is fundamental to ensuring continuous, high-yield, and low-cost operation of the entire production line.

The BAICHY PE600x900 (feed opening size 24 inches x 35 inches) jaw crusher is a classic model designed to handle this core task. It can handle a maximum feed size of up to 500mm, with an adjustable discharge opening range of 65-160mm, making it an ideal choice for the primary crushing stage in medium-sized production lines.

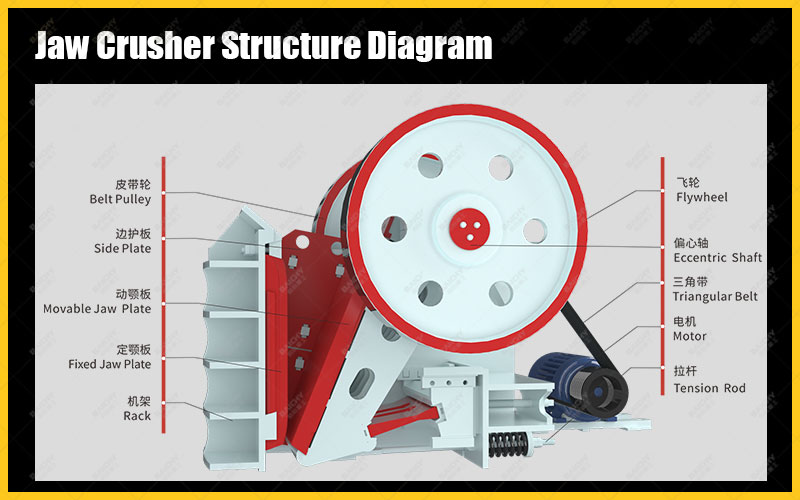

II. Equipment Overview: Classic Structure, Mature and Reliable

As a mining equipment manufacturer with 20 years of professional manufacturing experience, Northern Heavy Industry deeply understands the fundamental needs of the market for primary crushing equipment. The PE series jaw crusher adopts the classic "toggle plate" mechanical design structure, which has been proven in the global market for decades, and is known for its simple structure, easy maintenance, and low operating costs.

| Key Words | Primary Crushing |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤500mm |

| Motor Power | 55kw |

| Capacity | 90-180t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

PE jaw crusher structure diagram

III. Core Advantages: Excellent Performance Forged by 20 Years of Expertise

1. Exceptional Durability: Key components such as the movable and fixed jaw plates are made of high-strength manganese steel castings and undergo special heat treatment processes, resulting in extremely high wear resistance and impact resistance, effectively extending the replacement cycle of wear parts.

2. Deep "V" Shaped Crushing Chamber: The optimized chamber design ensures that material begins crushing at the top of the crushing chamber, preventing material blockage, improving crushing efficiency and throughput, and achieving higher output.

3. Stable and Reliable Overall Structure: The frame adopts an integral cast steel or welded structure, ensuring excellent rigidity and stability during high-intensity, high-impact crushing operations, resulting in low vibration and smooth operation.

4. Convenient Adjustment and Maintenance: The discharge opening uses a wedge adjustment device, which is convenient and offers a wide adjustment range. All lubrication points are centrally located, making daily maintenance simple and easy, effectively reducing downtime.

5. Wide Material Adaptability: Suitable for primary crushing of various hard and medium-hard materials such as granite, basalt, river pebbles, limestone, iron ore, and construction waste, making it a true "all-rounder."

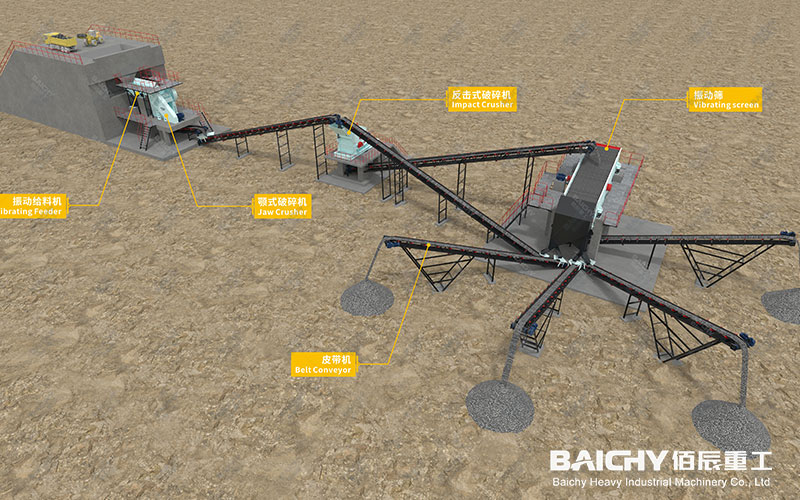

Stationary crushing production line

IV. Application Cases: Successful Practices Validate Strength

In a granite quarry project with a daily output of 2000 tons, the customer's original primary crusher had a high failure rate and unstable output. After replacing it with the BAICHY PE600x900 jaw crusher:

- Increased Output: The average hourly output stabilized at over 110 tons, fully meeting the material supply requirements for subsequent secondary crushing.

- Reduced Operating Costs: The wear life of the wear-resistant jaw plates was extended by approximately 30%, and lubrication and maintenance time was reduced by approximately 5 hours per week, significantly lowering overall operating costs.

- Excellent Stability: After 6 months of continuous operation, there were no unplanned shutdowns due to main equipment failures, and the customer highly praised the reliability of the equipment.

Jaw Crushing Plant

V. Related Equipment Recommendations

To achieve optimal crushing results and production efficiency, we usually recommend combining the PE600x900 with the following equipment to form an efficient production line:

- Feeding Equipment: ZSW series vibrating feeder, for uniform and continuous feeding, maximizing the efficiency of the jaw crusher.

- Secondary Crushing Equipment: PF series hard rock impact crusher or PY series spring cone crusher, used for medium and fine crushing to produce finished aggregates of different specifications. - Screening Equipment: YA series circular vibrating screen for efficient classification, ensuring the finished product meets the required particle size.

- Conveying Equipment: TD series belt conveyor, connecting various process stages to form an automated production line.

VI. Frequently Asked Questions (FAQ)

Q1: What is the maximum material hardness that the PE600x900 can handle?

A1: This equipment can effectively crush various minerals and rocks with a compressive strength not exceeding 320MPa, such as most granite, basalt, and quartz.

Q2: Does the equipment delivery include installation guidance?

A2: Yes. We provide a complete set of technical documents, including detailed installation foundation drawings and electrical schematic diagrams. We can also dispatch engineers for on-site installation, commissioning guidance, and technical training upon customer request.

Q3: What is the approximate lifespan of the key wear parts?

A3: This depends on the abrasiveness of the material being crushed. Taking medium-hardness granite as an example, under normal working conditions, a set of high-manganese steel jaw plates typically lasts 6-12 months. We provide high-quality original spare parts to ensure optimal equipment performance.

Q4: What is the power consumption of the equipment?

A4: The matching motor power is 55-75kW. In actual operation, the actual power consumption will vary depending on the material and discharge opening settings. It is a highly efficient crushing equipment with excellent energy consumption performance.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.