Coal Hammer Crusher | Heavy Hammer Crusher

In the field of mining crushing, coal, as an important energy mineral, has always been a focus of the industry due to the need for efficient and environmentally friendly crushing processes. As a mining crushing equipment manufacturer with 20 years of professional experience, we understand that choosing the right crushing equipment is crucial for improving coal processing efficiency and reducing operating costs.

Coal hammer crushers, especially heavy-duty hammer crushers, have become one of the core pieces of equipment in coal crushing production lines due to their unique structural design and powerful crushing capabilities.

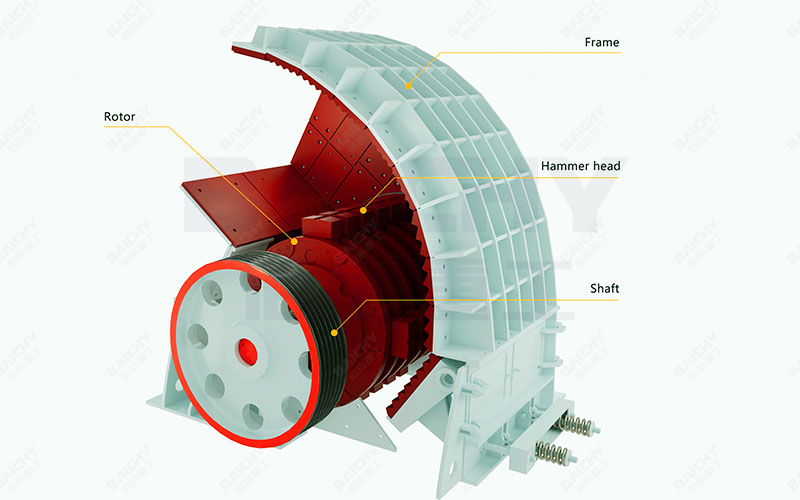

I. Overview of Coal Hammer Crushers: The Core Structure of Heavy-Duty Hammer Crushers

Coal hammer crushers, commonly known as heavy-duty hammer crushers, are devices that utilize high-speed rotating hammers to impact materials, causing them to break along natural fissures, bedding planes, and joint surfaces. Its core structure includes:

1. Rotor Assembly: Consists of the main shaft, hammer disc, hammer shaft, and hammers, and is the power and execution center of the crusher.

2. Crushing Chamber: Uses heavy-duty impact liners to create an efficient impact crushing space.

3. Grate Screen: Controls the output particle size to ensure the product meets specifications.

4. Drive System: Usually composed of a motor, pulley, and V-belt, which transmits power.

The design of heavy-duty hammer crushers is specifically tailored to the characteristics of medium-hard and less abrasive materials such as coal, achieving highly efficient "one-step" crushing, reducing the number of crushing stages, and simplifying the process flow.

Structural diagram of a heavy-duty hammer crusher

II. Outstanding Advantages of Heavy-Duty Hammer Crushers in Coal Crushing

Based on twenty years of manufacturing and technical service experience, we have summarized five core advantages of coal hammer crushers (heavy-duty hammer crushers):

1. Large Crushing Ratio and Excellent Capacity: Heavy-duty hammer crushers have a crushing ratio of up to 40-50, capable of crushing large lumps of raw coal to the required particle size in one go. The high single-machine output significantly improves the processing capacity of the entire production line.

2. Low Operating Costs and Easy Maintenance: The equipment has a compact structure, and wear parts (such as hammers) are made of wear-resistant materials such as high-chromium alloy, resulting in a long service life. The unique hinged hammer design allows for quick replacement by only one person, greatly reducing maintenance time and labor costs.

3. Excellent Product Particle Shape and Minimal Over-crushing: Utilizing the impact crushing principle, the finished material is mostly cubic in shape with uniform particle size and low needle-like and flaky content, making it particularly suitable as raw material for power coal or briquettes. The optimized grate bar structure effectively controls over-crushing, improving coal utilization efficiency.

4. Enhanced Intelligence and Adaptability: Modern heavy-duty hammer crushers can be equipped with a PLC intelligent control system to monitor bearing temperature and vibration in real time, enabling early warning and protection. Simultaneously, by adjusting the grate bar gap, it can flexibly adapt to different discharge particle size requirements, allowing for multi-purpose use.

5. Outstanding Environmental Performance: The equipment operates smoothly with low vibration. It can be equipped with dry fog dust suppression or enclosed covers to effectively control dust dispersion during the crushing process, meeting increasingly stringent environmental standards.

Heavy-duty hammer crusher customer site

III. Application Cases: Performance of Heavy-Duty Hammer Crushers in Actual Coal Production Lines

Case Background: A large open-pit coal mine in North China originally used a two-stage crushing system of "jaw crusher + impact crusher," which had problems such as complex process flow, high energy consumption, and difficulty in dust control.

Solution: We recommended and provided a heavy-duty hammer crusher with a capacity of 800 tons per hour as the core crushing equipment, adopting a single-stage crushing and screening process of "heavy-duty hammer crusher + mobile screening station."

Implementation Results:

Improved Efficiency: The process flow was simplified, system power consumption was reduced by approximately 25%, and production capacity stably reached the design requirements.

Reduced Costs: The cost of wear parts was reduced by more than 30% compared to the original system, and maintenance workload was significantly reduced.

Environmental Compliance: Combined with enclosed belt conveyors and a centralized dust removal system, the dust concentration in the working area was far below national standards.

Fast Return on Investment: Due to the high efficiency and reliability of the equipment, the investment is expected to be recovered within 14 months through cost savings.

IV. Equipment Selection and Related Recommendations

Selecting a suitable coal hammer crusher requires considering multiple factors:

Material Characteristics: Key considerations include the hardness (Proctor hardness), moisture content, gangue content, and maximum feed size of the coal. Capacity Requirements: Determine equipment specifications based on hourly processing capacity and annual operating time.

Discharge Requirements: Clearly define the final product particle size distribution (e.g., 0-30mm, 10-50mm, etc.).

Process Layout: Consider site limitations and choose between fixed or mobile heavy-duty hammer crusher units.

Recommended Related Equipment:

1. Feeding Equipment: Heavy-duty plate feeder to ensure uniform and stable feeding to the heavy-duty hammer crusher.

2. Iron Removal Equipment: Powerful belt magnetic separator to pre-remove iron and other impurities from the coal, protecting the hammer heads from accidental damage.

3. Screening Equipment: Circular vibrating screen or flip-flop screen, forming a closed-loop or open-loop system with the heavy-duty hammer crusher for precise classification.

V. Frequently Asked Questions (FAQ)

Q1: Can the heavy-duty hammer crusher handle wet and sticky coal?

A1: Yes, but it requires a specific design. For high-humidity, easily clogging coal, we use an anti-clogging design in the grate discharge area (such as a grate-less adjustable or heated grate), and increase the discharge space of the crushing chamber to ensure smooth passage.

Q2: What is the service life of the hammer heads? Is replacement complicated?

A2: The service life of the hammer heads is directly related to the abrasiveness of the coal (especially the gangue content), usually reaching hundreds to thousands of hours under high-abrasion conditions. Replacement is very simple; open the inspection door, pull out the hammer shaft, and replace them one by one. It can be operated by a single person, resulting in short downtime.

Q3: Can a single-stage heavy-duty hammer crusher completely replace traditional two-stage crushing?

A3: In most coal crushing scenarios, yes. The large crushing ratio and high capacity of the heavy-duty hammer crusher allow it to crush large lumps of raw coal ≤1200mm to less than 50mm in one pass, completely replacing the traditional "jaw crusher + impact crusher/cone crusher" two-stage system, resulting in lower investment and a simpler process.

Q4: How does the equipment ensure long-term operational stability?

A4: The key lies in the quality of critical components and intelligent monitoring. We use heavy-duty cast steel rotors with high dynamic balancing accuracy; equipped with bearings from brands such as SKF/TIMKEN; and integrate an online condition monitoring system to provide real-time vibration and temperature data, enabling preventive maintenance and avoiding unexpected downtime.

Coal hammer crushers, especially technologically mature heavy-duty hammer crushers, have become one of the best choices for modern coal crushing production lines due to their comprehensive advantages of high efficiency, energy saving, reliability, and environmental friendliness. As an equipment manufacturer with twenty years of experience in the industry, we not only provide equipment with excellent performance but are also committed to providing customers with full-cycle solutions from design and installation to lifetime service, helping each customer create greater production value.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.