Vibrating Grid Feeder 100 tph

The bar vibrating feeder is an indispensable key piece of equipment in industries such as mining, metallurgy, and building materials. It can uniformly, regularly, and continuously feed lumpy and granular materials from storage bins to receiving devices. As a mining equipment manufacturer with 20 years of experience, we deeply understand the importance of the bar vibrating feeder in the entire production line—it not only provides continuous and uniform feeding for crushing machinery but also performs coarse screening of materials, making it a core component of combined crushing and screening equipment.

Working Principle and Technical Features

Vibrating feeder structure

The bar vibrating feeder uses a vibrating motor as the excitation source. Centrifugal force is generated by the rotation of an eccentric block, causing the screen box and vibrator to perform forced continuous circular motion. When the vertical component of the acceleration of the feeding trough vibration exceeds the acceleration due to gravity, the material in the trough is thrown up and jumps forward along a parabolic trajectory, completing the throwing and falling process within 1/50th of a second. Due to the continuous excitation of the vibrating motor, the material is continuously thrown up and jumps forward at a frequency of 3000 times per minute, achieving the purpose of uniform and continuous feeding.

Core Advantages

1. High-Efficiency Processing Capacity

• Processing capacity up to 80-1000 t/h, meeting the needs of different production scales

• Adopts a double eccentric shaft vibrator structure, providing strong excitation force and large feeding capacity

• Vibration intensity up to 4.0G, increasing processing capacity by more than 20% compared to traditional feeders

2. Energy Saving and Environmental Protection

• Vibration motor as the excitation source, low noise and low power consumption

• Adjustable excitation force, allowing for easy and stable flow control and adjustment

• Enclosed body structure prevents dust pollution

3. Reliable Structure

• Stable vibration, reliable operation, and long service life

• Simple structure, reliable operation, and convenient adjustment and installation

• Lightweight, compact, and easy to maintain

Technical Parameters for a 100 Ton/Hour Processing Capacity

For a processing capacity of 100 tons of material per hour, we recommend the following technical specifications:

| Parameter Item | Technical Indicators |

| Processing Capacity | 80-120 t/h |

| Maximum Feed Particle Size | 400mm |

| Motor Power | 1.5×2kw |

| Vibration Frequency | 16Hz |

| Dual Amplitude | 2-5mm |

| Dimensions | 3100×1800×1600mm |

| Weight | Approx. 3895kg |

Note: Actual processing capacity can be adjusted according to material specific gravity, moisture content, etc. A 10° downward tilt can increase processing capacity by 5%-10%, and a 15° downward tilt can increase it by 50%-100%.

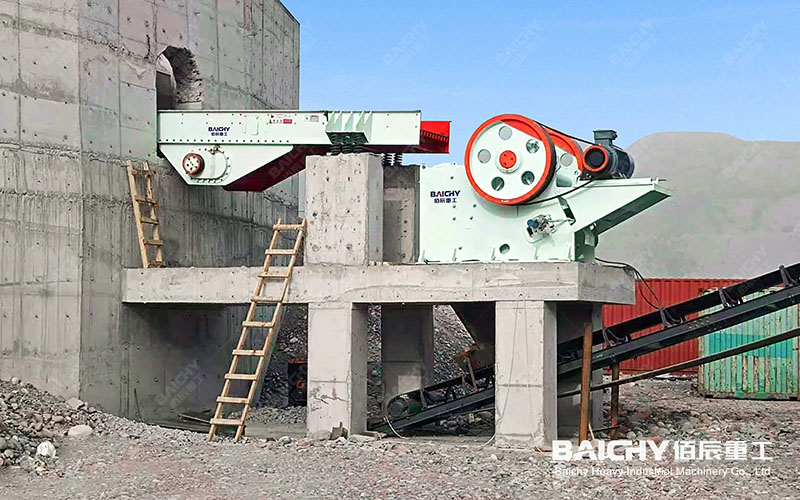

Vibrating feeder on-site operation diagram

Application Areas and Case Studies

Application Areas

Vibrating bar feeders are widely used in:

• Metallurgical Industry: Crushing and screening of metal minerals such as iron ore and copper ore

• Coal Mining Industry: Conveying and screening of raw coal

• Mineral Processing Industry: Feeding before coarse crushing of various ores

• Building Materials Industry: Crushing production lines for building materials such as limestone and granite

• Chemical Industry: Uniform feeding of chemical raw materials

• Abrasive Industry: Conveying and screening of abrasive materials

Successful Case Studies

Case Study 1: Large-scale sand and gravel aggregate production line in Southeast Asia

• Configuration: GZD-800×3000 vibrating bar feeder

• Processing Capacity: 100t/h

• Material: Granite

• Operating Results: Continuous and stable operation for over 2000 hours without any downtime, providing uniform feeding for jaw crushers, increasing overall production efficiency by 15%

Case Study 2: Mexican iron ore beneficiation plant

• Configuration: ZSW-490×110 Vibrating Feeder

• Processing Capacity: 150-320t/h

• Material: Iron ore

• Operating Effect: Effectively removes mud and impurities, significantly improves pre-screening effect, and reduces crusher load by 18%.

Selection Guide

When selecting a grid vibrating feeder, the following key factors need to be considered:

1. Material Characteristics

• Material Particle Size: Select the appropriate model based on the maximum feed particle size.

• Material Specific Gravity: Different specific gravities require adjustments to the processing capacity calculation.

• Moisture Content: High moisture content materials require a model with better anti-clogging performance.

2. Processing Capacity

• Matches the output of the entire production line.

• Coordinates with the processing capacity of the downstream crushing equipment.

• Avoids excessive feed rate causing crusher overload or blockage.

3. Installation Space

• Selects equipment of appropriate size based on actual site conditions.

• Considers that the effective discharge opening of the hopper should not exceed one-quarter of the hopper width.

• The optimal inclination angle for the rear wall of the silo is 55-65 degrees.

4. Energy Consumption and Maintenance

• Choose a model with low energy consumption and easy maintenance.

• Consider long-term electricity and maintenance costs.

• Prioritize equipment with advanced technology and long service life of wear parts.

Recommended Models

Based on a processing capacity of 100 tons/hour, we recommend the following models:

GZD-800×3000

• Tank Dimensions: 850×3000mm

• Processing Capacity: 80-120t/h

• Motor Power: 1.5×2kw

• Applicable Scenarios: Small and medium-sized sand and gravel production lines, mineral processing plants

ZSW-490×110

• Tank Dimensions: 490×110mm

• Processing Capacity: 150-320t/h

• Motor Power: 22kw

• Applicable Scenarios: Medium-sized mines, building material factories

Frequently Asked Questions (FAQ)

Q1: What should I do if the vibrating feeder does not vibrate or operates intermittently after startup?

A: First, check if the vibrating motor fuse is blown or if the coil is short-circuited. Replace the fuse promptly and inspect the coil. Second, check if the protective cover is damaged and if it is rubbing against the eccentric block. If damaged, repair or replace it, and adjust the eccentric block angle. It is recommended to check and tighten all bolts daily during the first week of equipment use. After one week, check every other day.

Q2: What are the reasons for insufficient feed or uneven discharge from the feeder?

A: Possible causes include: The hopper load compresses the feeder trough, causing fatigue damage to the spring plate and connecting fork; excessive feed causing material accumulation; small vibration amplitude, preventing the vibrator from properly adjusting the amplitude; the vibrator's SCR is broken down; the air gap between the core and armature is not within the standard range. Solutions: Reduce the feed rate and maintain uniformity; clear blockages; replace the vibrator's SCR; adjust the air gap to the standard value of 2mm.

Q3: What should I do if the equipment makes abnormal noise or loud impact sounds during operation?

A: Check if the anchor bolts or the bolts connecting the vibrator and the tank are loose or broken. Tighten or replace them promptly. Check if the vibration spring is broken; replace it if necessary. Check if the vibration motor voltage is stable and maintain the rated operating voltage. It is recommended to check moving parts for abnormal noises monthly to identify potential problems early.

Maintenance Recommendations

Daily Maintenance

1. Regular Inspection: Check the equipment's operating status every shift, observing the stability of amplitude, current, and noise.

2. Bolt Tightening: Retighten bolts after 3-5 hours of equipment operation, especially the foundation bolts of the vibratory motor.

3. Lubrication Maintenance: Add grease to the motor bearings every 2 months, and monthly during high-temperature seasons.

4. Regular Dust Removal: Keep the equipment surface clean to prevent dust accumulation from affecting heat dissipation.

Regular Maintenance

1. Vibrator Inspection: Inspect the vibrator bearings every six months and replace worn parts.

2. Spring Inspection: Check the vibration springs for fatigue damage or breakage.

3. Liner Inspection: Inspect the wear of the tank liner and replace it promptly.

4. Electrical Inspection: Check for loose motor wiring and ensure the control circuit is functioning correctly.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.