Professional processing of 20-50mm anthracite, consistently controlling moisture content to ≤2%, and utilizing closed-loop dust removal throughout the process to ensure compliance with emission standards.

Anthracite is highly sought after in the energy and industrial materials sectors for its high fixed carbon content, low volatile matter, and high calorific value. However, the transition from raw material to high-quality finished product often requires critical pre-processing steps such as crushing and drying. Faced with stringent industrial standards and environmental requirements, efficiently and cleanly processing 20-50mm anthracite to the target particle size while strictly controlling moisture content (≤2%) has become a core requirement for many companies. An intelligent system integrating crushing, drying, and dust removal offers the perfect solution to this problem.

1. Solving the Particle Size Challenge: Precision Crushing Technology

Anthracite is hard and wear-resistant. Traditional crushing methods can easily lead to over-crushing or uneven particle size, resulting in resource waste and reduced product value. Modern high-efficiency crushing solutions utilize a multi-stage crushing concept and laminated crushing principles. Through a "coarse + fine crushing" process, combining the efficient primary crushing of a jaw crusher with the precise fine crushing of a cone crusher, they not only consistently process 20-50mm raw materials to a target particle size of 1-10mm or even finer, but also achieve a more concentrated product particle size distribution and significantly reduce over-crushing. Optimized crushing chamber geometry and speed control not only improve efficiency but also significantly reduce energy consumption and wear parts wear, resulting in more economical operating costs.

2. High-efficiency, low-cost drying process

Moisture content is a key indicator affecting the performance of anthracite coal. Excessive moisture content reduces calorific value, affects reaction efficiency, and can even cause blockages in subsequent processing steps. Traditional drying methods often consume a lot of energy, have low thermal efficiency, and are prone to oxidation. Modern high-efficiency drying systems utilize indirect heating and waste heat recovery technology. Through precise temperature and air speed control, they ensure uniform heating of the anthracite coal during the drying process, preventing local overheating and inadequate drying. The innovative three-stage drying process (pre-drying, main drying, and homogenization) not only stably controls moisture content below 2% but also maximizes the preservation of anthracite's physical and chemical properties. The system's integrated hot air circulation device significantly reduces energy consumption, achieving green and low-carbon operation.

3. Fully Closed-Loop Dust Removal System

Anthracite easily generates dust during the crushing, conveying, and drying processes. This not only causes material loss but also puts a strain on the working environment and surrounding ecology. With increasingly stringent environmental regulations, dust removal has become an essential component of any project. The integrated solution employs a comprehensive dust control strategy: high-efficiency dust collection hoods are installed at key dust-generating points, such as the crusher discharge, conveyor transfer points, and drying kiln entrances and exits. These dust is then directed to a centralized treatment system through negative pressure extraction. A two-stage purification process, combining cyclone dust removal and pulse bag dust removal, achieves dust removal efficiencies exceeding 99.9%, ensuring emissions are well below national standards. Collected coal dust is returned to the system for reuse, achieving the dual goals of zero waste and clean production.

4. Why choose an integrated solution?

• Doubled Efficiency: Seamless integration of the crushing and drying processes reduces intermediate steps, lowering energy consumption and operating costs.

• Intelligent Control: A central control system monitors key parameters such as particle size, moisture, and temperature in real time to ensure product stability.

• Environmental Compliance: A full-system dust removal design helps companies easily comply with environmental inspections and establish a green brand image.

• High Return on Investment: Durable equipment with a high degree of automation delivers significant long-term operational benefits.

From raw materials to finished product, every step is precise and efficient; from production to discharge, every link is clean and environmentally friendly. We are committed to providing customers with anthracite deep processing solutions that not only meet their needs but exceed their expectations, helping them gain an advantage in the market competition.

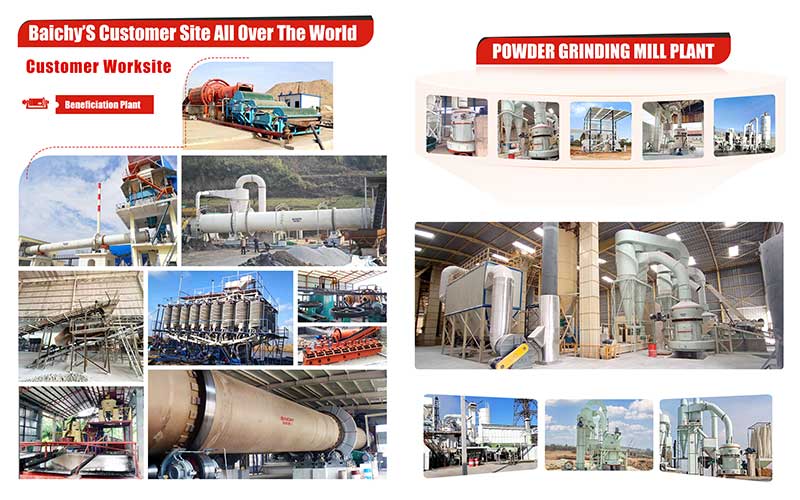

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)