PE600x900 Jaw Crusher Manufacturer | SGS/CE/ISO Certified

In mining operations, aggregate production, and large-scale construction projects, choosing a reliable, efficient, and compliant primary crushing equipment is crucial for success. The PE600x900 jaw crusher, a classic core component of medium-to-large crushing production lines, derives its value not only from its durable design and superior performance but also from the international quality and safety standards it represents—SGS, CE, and ISO triple certification.

As a mining crushing equipment manufacturer with 20 years of extensive experience, we understand that certification is more than just a few certificates; it's the cornerstone of our commitment to our customers.

| Key Words | PE600x900 Jaw Crusher Manufacturer |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤500mm |

| Motor Power | 55kw |

| Capacity | 90-180t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

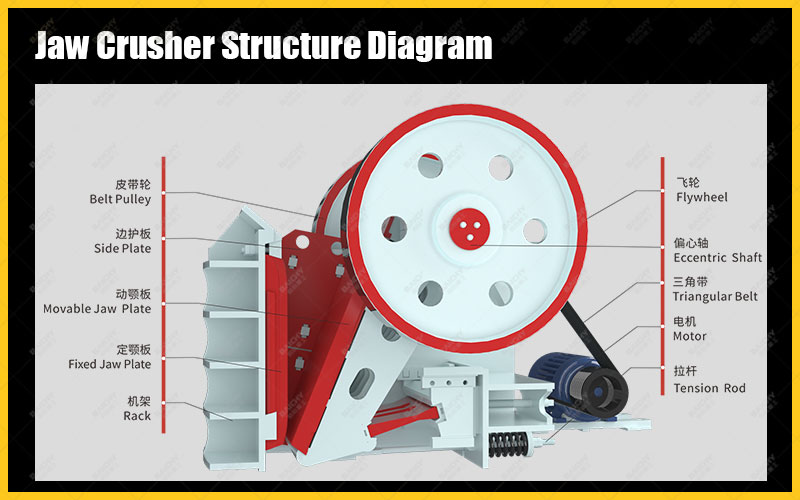

PE jaw crusher structure diagram

The theme PE600x900 Stone Jaw Crusher, SGS/CE/ISO Certified precisely addresses the core purchasing needs of high-end global customers.

• PE600x900: Defines the specific model and capacity of the equipment (feed opening size 600x900mm), representing the core technical parameters.

• Stone Jaw Crusher: Clearly identifies the equipment type and application field, serving as a fundamental keyword.

• SGS/CE/ISO Certification: This is the soul of the theme. It conveys multiple layers of assurance to customers:

◦ ISO certification: Represents that the manufacturer has a stable, controllable, and continuously improving quality management system, ensuring that every piece of equipment leaving the factory meets consistently high standards.

◦ CE certification: Is the passport for products entering the European market, proving that the equipment meets the strict health, safety, and environmental requirements of the European Union, and that its electrical system and mechanical design have reached advanced international safety levels.

◦ SGS certification: As a leading global inspection, testing, and certification organization, SGS certification provides authoritative third-party endorsement, enhancing customer trust in the authenticity of product specifications, performance, and quality.

The combination of these three certifications elevates an ordinary crusher to the level of an internationally compliant and reliable product, significantly reducing customer purchasing risks.

Equipment Overview: Classic Design, a Pillar of Strength

The PE600x900 jaw crusher is a robust and high-output primary crushing equipment. Its feed opening size is 600mm x 900mm, with a maximum feed size of up to 500mm. The discharge opening is adjustable from 65-160mm, and the hourly output is between 90-180 tons (depending on material properties and discharge setting). It adopts a classic V-shaped crushing chamber design, using the periodic reciprocating motion of the movable jaw to crush the stone, making it particularly suitable for primary crushing of high-hardness materials such as granite, basalt, and river pebbles.

Core Advantages: Why choose our triple-certified equipment?

1. Unparalleled Reliability: Based on 20 years of manufacturing experience, we use high-strength cast steel components (such as the movable jaw and frame) and heavy-duty eccentric shafts. The core components of the equipment are durable and can withstand high-intensity continuous operation.

2. Excellent Crushing Efficiency: The optimized crushing chamber design and larger stroke design improve processing capacity and finished product yield, reduce the content of flaky and elongated particles, and create favorable conditions for the next stage of crushing.

3. Extremely Low Operating Costs: The flywheel design effectively balances energy consumption and ensures stable operation. Wear parts (jaw plates) are made of high-manganese steel, which is highly wear-resistant and easy to replace, significantly reducing long-term maintenance costs.

4. Global Certification and Safety Assurance: SGS/CE/ISO certification ensures that the equipment meets the stringent requirements of international markets and large-scale engineering project tenders. Its safety design maximizes protection for operators.

5. Strong Adaptability: Whether for fixed production lines or mobile crushing plants, the PE600x900 is an ideal primary crushing unit, with flexible power configurations (electric or diesel engine driven).

Stationary crushing production line

Success Story: Witnessing the Strength

In a large highway aggregate project in Southeast Asia, the client strictly required all equipment to have international certification. Our PE600x900 jaw crusher, as the primary crusher, combined with our cone crusher and sand making machine, formed a basalt crushing production line with an hourly output of 350 tons. Thanks to its stable output, extremely low failure rate, and safety features that fully comply with CE standards, the equipment has been operating without failure for over 2 years, winning high praise from the client and serving as an equipment model for their subsequent projects. Related Equipment Recommendations

An efficient production line requires not only an excellent primary crusher but also subsequent equipment that works in synergy:

• Secondary Crushing: We recommend our HPT/HST series multi-cylinder hydraulic cone crushers for medium and fine crushing, producing high-quality aggregates.

• Sand Making and Shaping: We recommend the VSI6X series vertical shaft impact crusher for producing high-quality manufactured sand.

• Feeding and Screening: Matching ZG series vibrating feeders and YKN series vibrating screens to form a closed-loop automated production system.

Frequently Asked Questions (FAQ)

Q1: What materials does the PE600x900 jaw crusher typically process?

A1: It is ideal for processing various ores and rocks with a compressive strength of no more than 320MPa, such as granite, basalt, river pebbles, limestone, iron ore, etc.

Q2: Does the equipment require frequent maintenance?

A2: Routine maintenance mainly focuses on lubrication and tightening checks. The main wear part is the jaw plate, and depending on the hardness of the material, the service life is usually several months to more than a year. Replacement is designed to be simple.

Q3: What are the practical benefits of SGS/CE/ISO certification for my local use?

A3: Even if not used in Europe, these certifications represent the top quality, safety, and environmental friendliness of the equipment. It ensures operator safety, reduces the risk of downtime due to equipment failure or accidents, and helps you pass stricter project audits.

Q4: Can I visit the factory and test the equipment?

A4: Absolutely! We welcome customers from around the world to visit our factory and our manufacturing workshop with 20 years of experience. We will arrange material testing for you so you can witness the equipment performance firsthand.

Q5: Do you provide installation guidance and technical support?

A5: We provide a full range of services, from basic drawings, installation guidance, and commissioning training to long-term after-sales support, ensuring the smooth operation of your production line.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.