In the mining, building materials, and road construction industries, jaw crushers are undoubtedly the heart of the production line, undertaking the most arduous primary crushing tasks. Faced with a dazzling array of brands and models on the market, how to choose a high-efficiency, durable, and cost-effective jaw crusher has become a core concern for many investors.

This article will act as your professional advisor, guiding you through a comprehensive understanding of jaw crushers, from their working principles and model differences to price factors and key selection considerations, helping you make the wisest investment decisions.

I. Understanding the Construction Site Giant Jaw: How Does a Jaw Crusher Work?

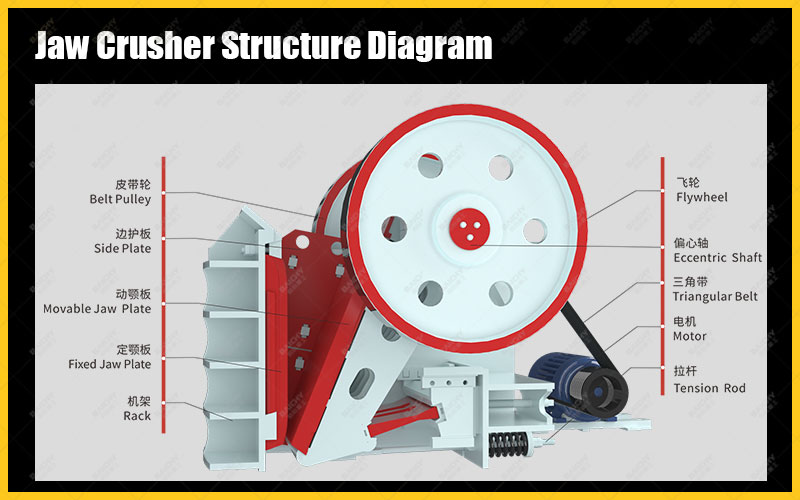

The working principle of a jaw crusher is simple and efficient, mimicking the movement of an animal's jaws. Its main structure includes a fixed jaw plate and a movable jaw plate. When material enters the crushing chamber from the feed inlet, the movable jaw plate periodically reciprocates against the fixed jaw plate, squeezing and grinding the material, thus crushing it. As the movable jaw plate moves away, the crushed material smaller than the discharge opening is discharged under gravity, achieving continuous operation.

This hard-on-hard compression crushing principle makes it particularly suitable for processing various hard materials with a compressive strength not exceeding 320MPa, such as granite, basalt, and river pebbles.

II. How to Choose the Right Model for You? Detailed Explanation of PE and PEX Series

Model selection is key to ensuring production efficiency and return on investment. The two most common series are the PE series and the PEX series.

• PE Series Jaw Crusher (First Choice for Coarse Crushing): Known for its large feed opening and high crushing ratio, it is the absolute mainstay of primary crushing. It is typically used in the first crushing stage of a production line, capable of crushing large pieces of raw stone to medium particle size.

◦ Features: Robust structure, high output, large feed size.

◦ Common Models: PE600×900, PE750×1060, PE900×1200, etc.

• PEX Series Fine Jaw Crusher (Fine Crushing Expert): Designed specifically for medium and fine crushing, producing finer and more uniform particle sizes. Commonly used in secondary crushing, it further processes materials crushed from PE series materials to obtain finished products that meet requirements.

◦ Features: Small discharge adjustment range, uniform product particle size, and aesthetically pleasing appearance.

◦ Common models: PEX250×1000, PEX300×1300, etc.

Selection suggestions: Determine the main model based on your maximum feed size and expected output (tons/hour), and then decide whether to configure a PEX series for secondary fine crushing based on the finished product particle size requirements.

III. Key Factors Affecting Jaw Crusher Prices

How much does a jaw crusher cost? This is a question without a standard answer; the price is affected by many factors:

1. Model and Specifications: This is the most important factor. The larger the equipment and the higher the output, the more expensive it will be. The price of a small laboratory jaw crusher (PE150×250) can differ from that of a large mining jaw crusher (PE1200×1500) by tens of times.

2. Technology and Configuration: Does it employ advanced welding technology? Do core components such as bearings and jaw plates use internationally renowned brands (e.g., SKF bearings, ZGMn13 high-manganese steel jaw plates)? Higher specifications mean longer service life and lower failure rates, but also a higher price.

3. Manufacturer Strength: Well-known brands, with their accumulated technology, quality control, and after-sales service, typically price their products higher than small workshops.

4. Market Demand and Supply Chain: Fluctuations in the price of raw materials such as steel directly affect equipment costs.

IV. Beyond Price: Four Key Considerations When Purchasing

Besides the initial purchase price, a savvy investor should also pay attention to the following:

• Wear Component Lifespan: Jaw plates are major wear parts. Their wear resistance directly affects long-term operating costs. Inquiring about the material and expected service life of the jaw plates is crucial.

• Energy Consumption: Choosing energy-efficient motors and equipment with optimized crushing chambers can save you significant electricity costs.

• After-sales service capability: Reliable manufacturers provide timely installation guidance, technical training, and spare parts supply to ensure the continuous and stable operation of your production line.

• On-site inspection and trial run: If conditions permit, visiting the factory in person and testing the machine with your materials is the most direct and effective way to verify equipment performance.

Conclusion: Choose us, choose stability and efficiency

As a professional manufacturer of mining crushing equipment, Baichy Heavy Industry understands your needs. Every jaw crusher we provide undergoes precise design and rigorous quality inspection to ensure excellent performance even under the most demanding operating conditions.

• Complete model range: From PE series to PEX series, we comprehensively cover various output and particle size requirements.

• Quality commitment: Using high-quality materials and core components, our equipment is robust, durable, and has a longer service life.

• Cost-effective choice: Through large-scale production and meticulous management, we offer you the most competitive prices.

• Comprehensive service: From site surveys and equipment selection to installation, commissioning, and after-sales support, we provide you with a one-stop solution.

Act now! If you are looking for a reliable jaw crusher for your project, please feel free to contact us. Our technical experts will recommend the most suitable equipment and provide a detailed quotation based on your specific working conditions and budget.