Introduction: Why Does the 100 TPH Stationary Crushing Solution Remain Popular?

In the mining and large-scale quarrying industries, a processing capacity of 100 tons per hour (100 TPH) is a classic and highly favored production benchmark. It meets the needs of medium to large-scale production projects while achieving the optimal balance between equipment investment, operating costs, and space layout. Although mobile crushing equipment is becoming increasingly popular due to its flexibility, for customers with stable raw materials, long production cycles, and a pursuit of ultimate efficiency and low operating costs, a well-designed 100 TPH stationary crushing plant remains an irreplaceable cornerstone. This article will delve into the core advantages, application scenarios, and investment value of the 100 TPH stationary crushing plant.

Overview of the 100 TPH Stationary Crushing Plant

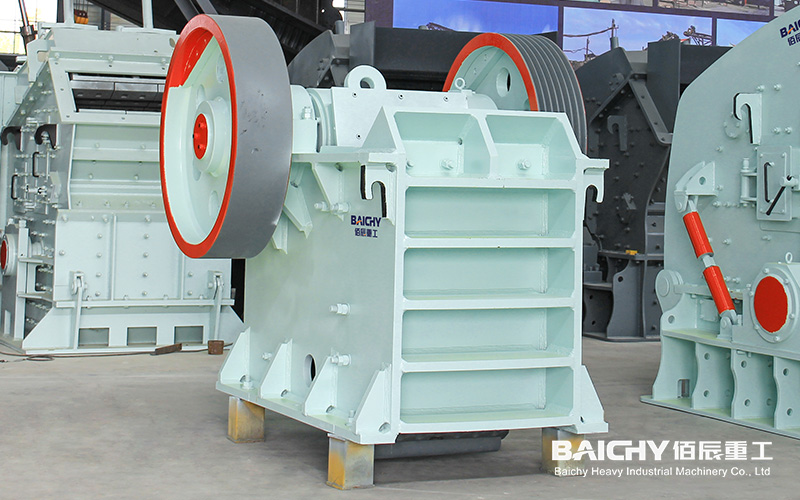

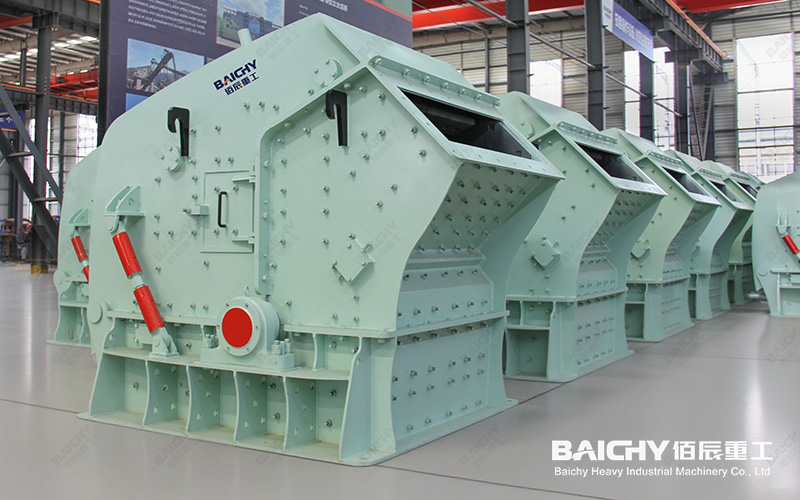

A 100 TPH stationary crushing plant is a complete fixed crushing production line system designed for continuous, large-scale crushing and screening operations at a fixed site. Its core objective is to achieve a stable output of 100 tons per hour of qualified aggregate (such as 0-5mm, 5-10mm, 10-20mm, etc.) with optimal energy consumption and labor input. The entire system typically includes feeding, primary crushing (mostly jaw crushers), secondary crushing (cone crushers or impact crushers), screening, conveying, and electrical control systems. All equipment is securely fixed through concrete foundations and steel structures, forming an efficient and continuous stationary aggregate production line.

Outstanding Advantages of Choosing a 100 TPH Stationary Crushing Plant

1. Excellent Stability and High Output

The stationary crushing plant has a solid foundation, low equipment vibration, and compact connections, enabling it to withstand long-term, high-load continuous operation. This ensures that the rated capacity of 100 TPH is stably and even exceptionally achieved, guaranteeing project supply and contract fulfillment.

2. Better Long-Term Economics (TCO)

Although the initial civil engineering investment is higher, stationary crushing equipment typically uses larger, more durable models with longer maintenance cycles, longer wear part life, and often lower unit energy consumption than mobile equipment of the same capacity. Over its 3-5 year lifecycle, it offers significant advantages in total cost of ownership (TCO).

3. High Automation and Low Labor Requirements

Fixed crushing production lines are easy to integrate with advanced central electronic control systems, enabling one-button start/stop, remote monitoring, fault alarms, and fully automated operation. This greatly reduces the number and skill requirements of operators and minimizes human error.

4. Greater Customization and Flexible Configuration

Customers can flexibly select the most suitable crusher type (such as a cone crusher for hard rock using lamination crushing, or an impact crusher for medium-hard rock using impact crushing) based on raw material hardness (such as granite, river pebbles) and desired output particle size, and design the optimal screening and circulation process to achieve the best finished product particle shape and gradation.

| Key Words |

Is a 100 TPH Stationary Stone Crushing Plant the Most Cost-Effective Solution for Your Long-Term Quarry Operation? |

| Product Model |

Stone Crushing Plant |

| Capacity |

0-2000t/h |

| Core Advantages |

Multi-stage fragmentation and reshaping |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Success Story: A Granite Quarry Project with an Annual Output of 300,000 Tons

Project Background: A large quarry in Central China, using high-hardness granite as raw material, required the production of various specifications of construction aggregates, with a designed annual output of 300,000 tons.

Solution: We designed and built a complete 100 TPH fixed crushing plant for them.

Core Configuration: PE600×900 jaw crusher (primary crushing) + HPT300 multi-cylinder hydraulic cone crusher (secondary crushing) + 3YK2460 vibrating screen (three-layer screening).

Operating Results: Since commissioning, the production line has operated smoothly, with an actual average capacity of 110-115 TPH. The finished aggregate has excellent particle shape and low flakiness content, fully meeting the standards for high-speed rail construction materials. The automation system requires only 2-3 operators per shift, and electricity consumption costs are reduced by approximately 15% compared to the original old production line.

Recommended Related Equipment

To build an efficient 100 TPH fixed crushing production line, in addition to the classic jaw crusher + cone crusher/impact crusher combination, the following key equipment can also be considered to improve overall efficiency:

Heavy-duty plate feeder: Ensures uniform and continuous feeding to the jaw crusher, preventing blockages, and is the "first line of defense" for stable production.

Circular Vibrating Screen (Multi-layer): Performs fine screening, enabling simultaneous production of multiple product specifications and improving the overall profitability of the production line.

Centralized Dust Removal System: Covers all dust-generating points, meeting environmental protection requirements and creating a green mine.

Intelligent Electrical Control Room: Integrates PLC control system and video surveillance, achieving intelligent management that is "visual, perceptible, and predictive."

Frequently Asked Questions (FAQ)

Q1: What is the approximate total investment for a 100 TPH fixed crushing plant?

A1: The price of a 100 TPH fixed crushing plant is not fixed; it mainly depends on the equipment brand and model selection, the complexity of the configuration (such as the number of crushing stages and screening layers), the degree of automation, and the amount of civil engineering work. For a basic configuration of a fixed crushing production line, the equipment investment typically ranges from RMB 1.5 million to 3 million. We recommend providing specific raw material information and finished product requirements to obtain an accurate quotation.

Q2: Should I choose a fixed plant or a mobile plant?

A2: The choice between fixed and mobile crushing equipment primarily depends on your production scenario. If your material source is fixed (such as your own mine), the production cycle exceeds 2-3 years, and you are pursuing the lowest per-ton production cost and highest stability, a 100 TPH fixed crushing plant is the ideal choice. If your work site requires frequent relocation (such as engineering demolition projects), space is limited, or you require extremely fast deployment, then a mobile plant is more suitable.

Q3: How long does it take from installation to commissioning?

A3: For a standard 100 TPH fixed crushing plant, the time frame is usually 2-4 months. This includes: preliminary foundation drawing design (1-2 weeks), on-site civil engineering construction (3-5 weeks), equipment hoisting and mechanical installation (2-3 weeks), and electrical installation and system debugging (1-2 weeks). The exact time depends on site conditions, weather, and the client's cooperation progress.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!