The 1200 wet pan mill is a grinding equipment widely used in the industrial field. Its core feature is that it participates in the grinding process through liquid media (such as water, oil or other solvents), which has the advantages of cooling, dust prevention, and improved material dispersion.

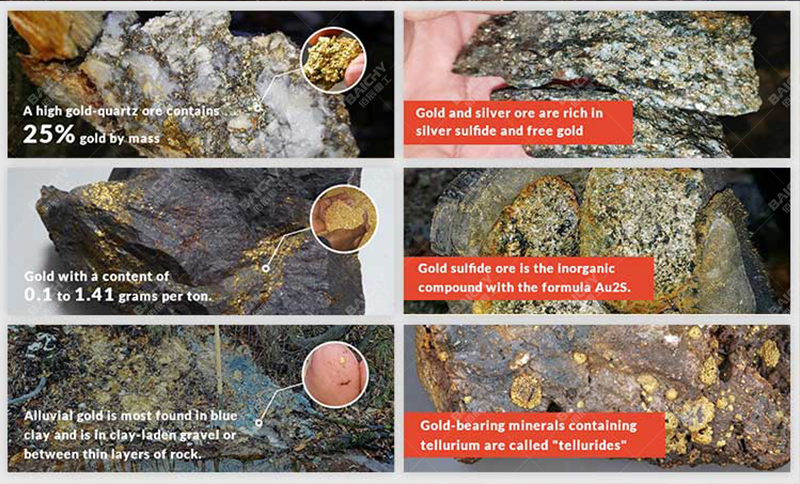

Applicable scenarios: coarse or fine grinding of metal ores and non-metallic ores (such as quartz, feldspar, fluorite, etc.).

| Key Words | 1200 Wet Mill Application Scenarios |

|---|---|

| Product Model | Wet Pan Mill |

| Feed Size | ≤30mm |

| Motor Power | 3-30kw |

| Capacity | 3-20t/h |

| Core Functions | Kinetic energy transfer + abrasion + hydraulic classification |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Function of the 1200 wet pan mill :

• Crushing the ore to the required particle size for subsequent flotation, magnetic separation or gravity separation.

• The liquid medium can suppress dust pollution and reduce equipment wear (especially for high-hardness ores).

• Applicable to slurry preparation in hydrometallurgy (such as hydrometallurgy copper smelting).

Application scenarios of 1200 wet pan mill in metal mines

1200 wet pan mill is mainly used for coarse grinding, fine grinding and slurry preparation of metal minerals, which are commonly used in the following links:

1. Ore pretreatment: After crushing the block ore (such as iron ore, copper ore, lead-zinc ore, etc.), it is further ground to a certain particle size (usually 0.1~3 mm) to prepare for subsequent flotation, magnetic separation or gravity separation processes.

2. Concentrate regrinding: Secondary grinding of the concentrate after roughing to improve the dissociation degree of useful minerals (such as the monomer dissociation of sulfides in copper concentrate).

3. Tailings treatment: Treat fine-grained minerals in tailings and recover residual valuable components (such as rare elements in rare earth ore tailings).

Working principle and basic process of 1200 wet pan mill

1. Feed: After crushing, the ore enters the mill through a feeding device (such as a screw conveyor).

2. Grinding: The grinding disc and roller rotate at high speed (usually 5~20 rpm) driven by the driving motor to form a centrifugal field. The material is squeezed, sheared and impacted between the grinding disc and the grinding roller, and a liquid medium (such as water or ore pulp) is added as a lubricant and grinding medium.

3. Classification: The ground material enters the classifier (such as a spiral classifier) through the overflow port, the coarse particles return to the mill for further grinding, and the fine particles enter the next process.

4. Discharge: The ore pulp with qualified fineness (usually 20%~40% solid-liquid ratio) is transported to flotation or subsequent processing.

The role of liquid medium in 1200 wet pan mill

1. Cooling: Reduce the heat generated by grinding and prevent the material from overheating and denaturing (such as oxidation of sulfide ore).

2. Lubrication: Reduce the wear of the grinding disc and grinding roller and extend the life of the equipment.

3. Dispersion: Prevent mineral particles from agglomerating and improve grinding efficiency.

4. Environmental control: suppress dust flying and improve workshop environment.

1200 wet pan mill core advantages

1. Low energy consumption: low friction resistance during wet grinding, 15%~30% lower power consumption than dry grinding.

2. High processing capacity: 1200mm wet pan mill diameter design can meet the continuous production needs of small and medium-sized mines (single unit processing capacity can reach 5~20 t/h).

3. High and uniform fineness: ultra-fine powder below **-0.074 mm (200 mesh)** can be achieved, meeting the requirements of mineral dissociation degree for flotation.

1200 wet pan mill environmental protection and safety

Fully enclosed structure + liquid medium, completely eliminate dust pollution, in line with mine environmental protection standards.

Avoid the risk of static sparks caused by dry grinding, suitable for the processing of flammable and explosive minerals (such as sulfur mines).

Strong wear resistance

Grinding discs and rollers can be equipped with rubber lining or high chromium alloy steel, which significantly extends the service life (especially for high-hardness ores such as hematite and ilmenite).

Process flexibility

Supports a variety of liquid media (water, oil or inhibitors), and can adjust grinding parameters (such as pH value, concentration) according to ore characteristics to optimize mineral processing indicators.

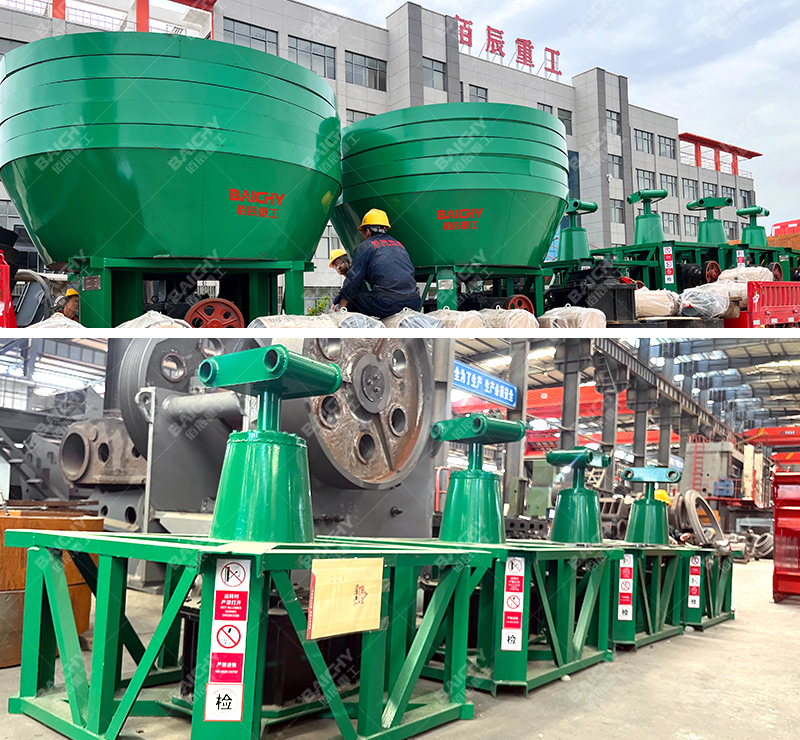

About of Baichy Heavy Industry

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)

Further reading:

How To Reduce The Energy Consumption Of Ball Mill? 5 Practical Energy-Saving Tips

Iron Ore Beneficiation Process: Magnetic Separation/Flotation/Gravity Separation