The following is a detailed description of the key steps and precautions for replacing the jaw head (also known as the jaw plate) of a jaw crusher:

Preparation Before Replacement

1. Shutdown and Power Off

• Completely stop the equipment, disconnect the power supply, and lock out the machine (LOTO procedure) to ensure safety.

• Wait until the material in the crushing chamber is completely drained, and clean out any remaining rock to prevent material from falling during replacement.

2. Tool and Spare Parts

• New jaw head (movable and fixed jaw plates must match models, such as PE-400×600).

• Special wrench, hydraulic jack, wire rope, lifting equipment (such as a crane), copper rod, grease, bolt loosening agent, etc.

3. Safety Inspection

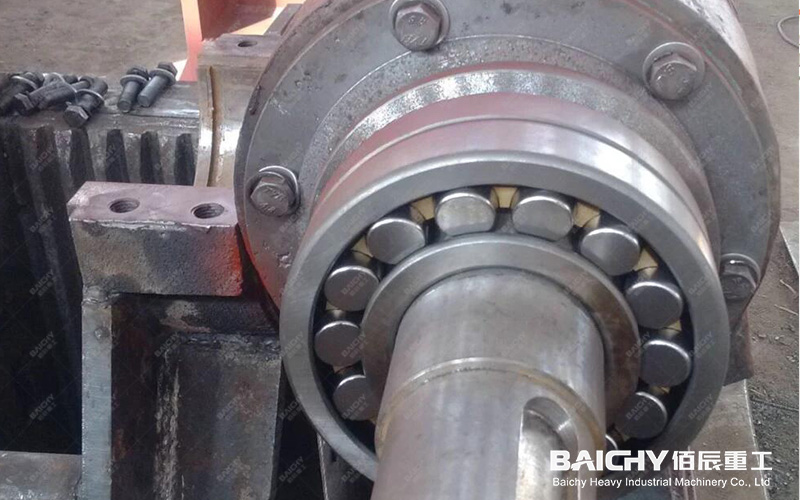

• Check the equipment's lubrication system to ensure that bearings and other components are not severely worn.

• Verify the condition of the mounting bolts. If rusted, spray them with loosening agent beforehand.

Replacement Procedure

1. Disassemble the Old Jaw Head

Step 1: Loosen the Fixings

• Use a hydraulic tool to loosen the wedge-shaped clamps or bolts on the back of the jaw plate (note that the bolts may lock due to vibration, so proceed slowly).

• If the jaw plate is segmented, mark the removal locations in order.

Step 2: Lift Out the Jaw Plate

• Use a lifting device to lift the jaw plate and gently tap it to separate it from the machine body (avoid damaging the bearing seat with forceful impact).

• Inspect the support pads (such as the toggle plate) on the back of the jaw plate for wear and replace them if necessary.

2. Install the New Jaw Head

Step 1: Cleaning and Inspection

• Clean the jaw plate mounting slots of the jaw plate and inspect the contact surface between the movable jaw bearing and the machine frame for damage.

• Apply molybdenum disulfide grease to the new jaw plate to reduce initial wear.

Step 2: Positioning and Securing

• Align the new jaw plate with the mounting slots and initially secure it with a jack or adjusting bolts.

• Align the segmented jaw plates according to the markings to ensure smooth joints (misalignment can cause premature wear).

Step 3: Tightening and Alignment

• Tighten the bolts diagonally to the specified torque (refer to the equipment manual; for example, M24 bolts require 450 N·m).

• Manually crank the movable jaw to check for smooth movement and no binding.

Post-Replacement Commissioning

1. No-Load Test Run

• Start the machine with a jog motion and observe for any abnormal vibration or noise. Verify that the bearing temperature rise is normal (≤70°C).

• Check the hydraulic system pressure (for example, to see if the over-iron protection device has reset).

2. Load Test

• Gradually load material to 50%, 80%, and 100% of the rated capacity, monitoring current fluctuations and crushing particle size to ensure compliance.

• Initially, avoid using the new jaw plates with extremely hard materials (such as granite) to extend their service life.

Precautions

1. Safety Regulations

• Never operate the machine until it is completely stationary. The crusher's high inertia can easily cause mechanical damage. • Wear a dust mask and goggles to prevent debris from flying during cleaning.

2. Maintenance Recommendations

• Regularly rotate the upper and lower jaw plates (e.g., every three months) to ensure even wear.

• Record replacement times and wear conditions, and analyze the jaw plate lifespan (usually 500-1200 hours, depending on material hardness).

3. Troubleshooting

• Broken bolts: Replace with high-strength bolts (grade 8.8 or higher) and use thread lock compound.

• Loose jaw plates: Stop the machine and re-tighten, inspecting the wedges for deformation.

Spare Parts Selection Recommendations

• Material: High manganese steel (Mn13Cr2) is suitable for medium-hard materials, while high-chromium cast iron (Cr20) offers better corrosion resistance.

• Tooth Profile Optimization: Select wavy or triangular tooth plates based on material characteristics to improve crushing efficiency.

Proper operation and regular maintenance can significantly extend jaw life and reduce equipment failure rates. If you encounter complex problems (such as cracks in the bearing seat), it is recommended to contact professional technicians for processing.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)