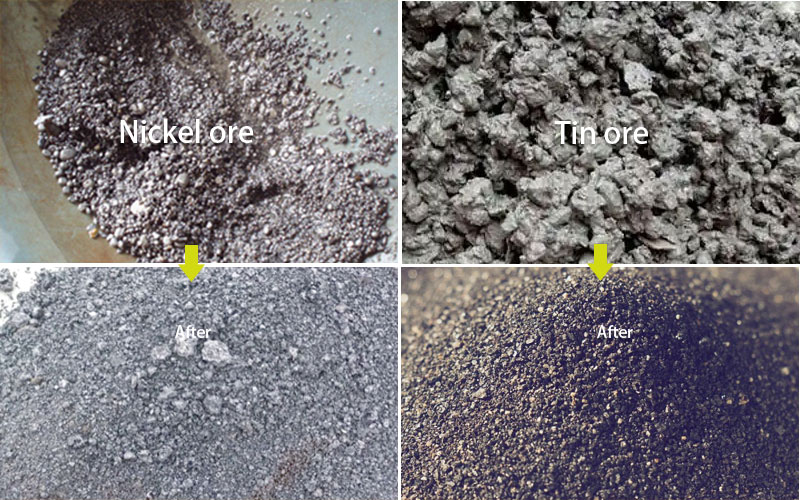

At tin and nickel mining sites in Indonesia and Malaysia, damp ore often becomes a hidden killer of production efficiency. High moisture content leads to soaring transportation costs, increased smelting energy consumption, and even compromises the quality of the final metal. A solution? Single-drum dryers are becoming key equipment for upgrading the Southeast Asian mining industry, helping companies reduce costs and increase efficiency with efficient, low-energy drying solutions.

1. Pain Points: Why is the Southeast Asian mining industry in urgent need of dryers?

1.1 Climate Challenges

Southeast Asia experiences frequent high temperatures and heavy rainfall (for example, Indonesia experiences an average annual rainfall of over 3,000 mm). The moisture content of mined ore can reach as high as 15-30%. Direct transportation or smelting results in:

• Transportation waste: Increased freight costs per ton of ore (the higher the moisture content, the higher the inefficient transportation costs).

• Smelting losses: Wet ore increases fuel consumption (for example, nickel ore smelting energy consumption can be reduced by over 10%).

1.2 Quality Requirements

• Nickel ore (latite nickel ore) must have a moisture content of ≤25% to meet smelter standards.

• Tin concentrate moisture content must be ≤12% to avoid agglomeration and grade degradation.

2. Solution: How do single-drum dryers empower the mining industry?

2.1 Efficient Dehydration, Direct Cost Reduction

• Single-drum dryers can process ore in batches (capacity of 1-20 tons/hour), rapidly evaporating moisture through high-temperature airflow, precisely controlling moisture content within the target range.

Case Study: After adopting a dryer, a nickel mining company in Sulawesi, Indonesia, reduced transportation costs by 18% and smelting fuel costs by 12%.

2.2 Strong Adaptability to Complex Ore Types

Due to the high viscosity of laterite nickel ore, a custom deagglomeration device can be added to prevent agglomeration within the drum.

Corrosion-resistant designs (such as 316L stainless steel linings) cope with the high salinity of Southeast Asia's air.

2.3 Environmental Compliance

• Enclosed drying reduces dust emissions, complying with Indonesia's Mining Environmental Protection Regulations for particulate matter emissions. • Waste heat recovery systems can reduce energy consumption by 30%, helping companies achieve carbon emission reduction targets.

3. Recommended Dryer Selection for Southeast Asian Mining Industries

3.1 Selection by Ore Type

• Nickel Ore/Laterite Ore: Prefer a large-diameter single-drum dryer (Ø2.2m or larger) with an anti-sticking design.

• Tin Ore/Concentrate Ore: Medium-sized dryer (5-10 tons/hour capacity) with a precise temperature control system.

3.2 Energy Adaptation

• Areas with stable power supply: Electric motor drive (e.g., the west coast of Malaysia).

• Remote mining areas: Diesel/biomass fuel models (e.g., the mining areas of Kalimantan, Indonesia).

3.3 Value-Added Features

• Intelligent Humidity Monitoring: Real-time adjustment of drying parameters to avoid over-drying or under-drying.

• Modular Design: Easy disassembly and transportation, adapting to mine relocation needs.

4. Success Stories: How Do Dryers Transform the Mining Production Chain?

Case Study: Tin Mine Project in Perak, Malaysia

Problem: Ore moisture content exceeded 20% during the rainy season, resulting in a 15% rejection rate at the concentrator.

Solution: Installed two gas-fired single-drum dryers with a capacity of 8 t/h.

Results:

• Moisture content was stably controlled at 10%-12%.

• Ore recovery rate increased by 7%, resulting in an annual revenue increase of over US$1.2 million.

With Indonesia tightening its ban on raw ore exports (starting in 2023, nickel ore must be processed to a moisture content of ≤25% before export), drying equipment has gone from being an option to an essential requirement. Whether it's boosting profit margins or addressing environmental scrutiny, single-drum dryers have become a strategic investment for Southeast Asian mining companies.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)