In industries such as building materials, brick and tile, and metallurgy, material crushing is the first critical step in the production line. However, traditional crushers are prone to clogging when dealing with high-moisture materials (such as coal gangue, shale, and slag), leading to frequent downtime, low output, and high maintenance costs, becoming a major headache for many companies. Today, we will introduce a revolutionary solution—the double-stage hammer crusher, which, with its unique design, is becoming a high-efficiency expert in the field of crushing medium- and low-hardness materials.

I. Core Advantages: Why Choose a Double-Stage Hammer Crusher?

The double-stage hammer crusher is not a simple upgrade, but a revolution in design philosophy. Its core advantages are mainly reflected in the following points:

1. High-efficiency one-time crushing, one machine replaces two: The equipment has two sets of rotor systems working in series. After the material is crushed by the upper rotor, it is immediately further crushed by the high-speed rotating lower rotor, thus achieving one-time crushing of the material. Secondary crushing is unnecessary, greatly simplifying the process and reducing equipment and infrastructure investment.

2. Unique screen-free design, preventing clogging with wet materials: This is its most prominent advantage. Traditional crushers rely on screen plates to control output particle size, which is prone to clogging with wet materials. The double-stage hammer crusher completely eliminates the screen plate, controlling particle size by adjusting the gap between the hammers and the liner, fundamentally solving the clogging problem of high-moisture materials, allowing for normal production even in rainy weather.

3. Unique output particle size, low energy consumption: Due to the two-stage continuous crushing, the material is fully crushed within the chamber, resulting in uniform and finely crushed output particles (most can be controlled below 3mm), and a high yield. Simultaneously, its optimized overall design significantly reduces energy consumption compared to two-stage inpidual crushers.

4. Stable operation, easy maintenance: The machine body has a compact structure, and wear parts such as the hammers are made of high-wear-resistant alloy materials, ensuring a long service life and easy replacement, guaranteeing the stability of long-term continuous operation.

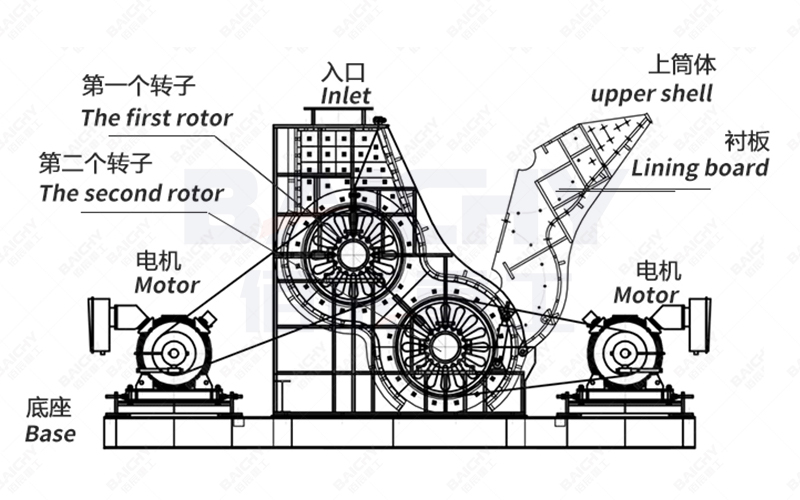

II. Working Principle: How does the dual rotor achieve powerful crushing?

The working principle of a double-stage hammer crusher is clear and efficient: Material enters the crushing chamber through the feed inlet and is first crushed by the high-speed rotating hammers on the upper rotor. Under the influence of gravity and the rotor, the crushed material quickly falls into the working area of the lower rotor. The lower rotor further crushes the material at an even higher speed. Material crushed to the specified particle size is discharged directly from the bottom of the machine without the need for screening.

III. Wide Range of Applications: Which industries and materials are best suited for it?

• Brick Industry: Ideal for crushing coal gangue and shale, providing high-quality raw materials for brick making.

• Building Materials Industry: Used for crushing limestone, gypsum, slag, etc., to produce cement or new building materials.

• Metallurgy and Chemical Industry: Processes ores, boric acid, and other materials with medium to low hardness.

• Energy Industry: Suitable for crushing coal, coke, etc.

In short, if your material has medium to low hardness and high moisture content, a double-stage hammer crusher is an excellent choice.

IV. How to Choose a Suitable Double-Stage Hammer Crusher Manufacturer?

When selecting equipment, in addition to focusing on the price of the double-stage hammer crusher, you should comprehensively consider the manufacturer's strength:

• Technology and Process: Understand the manufacturer's technological accumulation and manufacturing process.

• Material Quality: The material of core components (such as hammers and main shaft) directly determines the equipment's lifespan.

• Success Stories: Examine whether the manufacturer has application experience in relevant industries.

• After-Sales Service: Ensure timely installation, commissioning, and maintenance support.

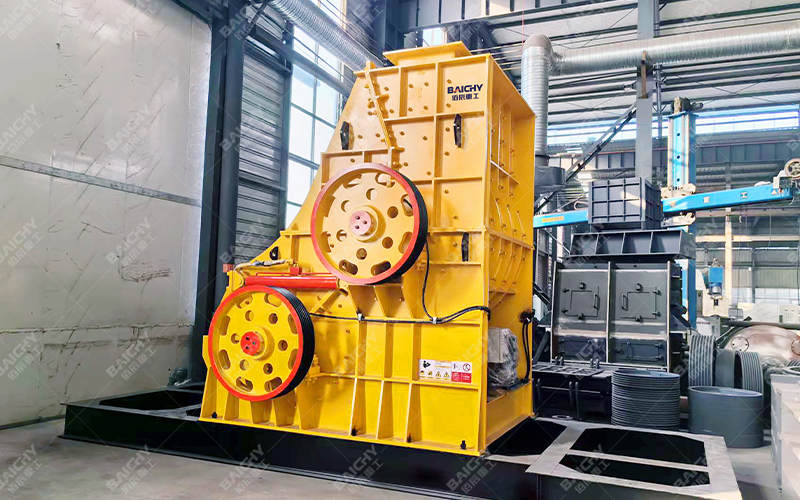

As a professional double-stage hammer crusher manufacturer, Baichy has many years of R&D and production experience, offering a complete range of product models and supporting customized services. We are committed to providing customers with crushing solutions that are not only efficient and reliable but also economical.

Contact us now for a customized solution and quote!

If you are troubled by material crushing problems, please feel free to contact our technical consultants. Please leave your material type, moisture content, and output requirements, and we will provide you with the most professional technical selection advice and the most competitive double-stage hammer crusher price.