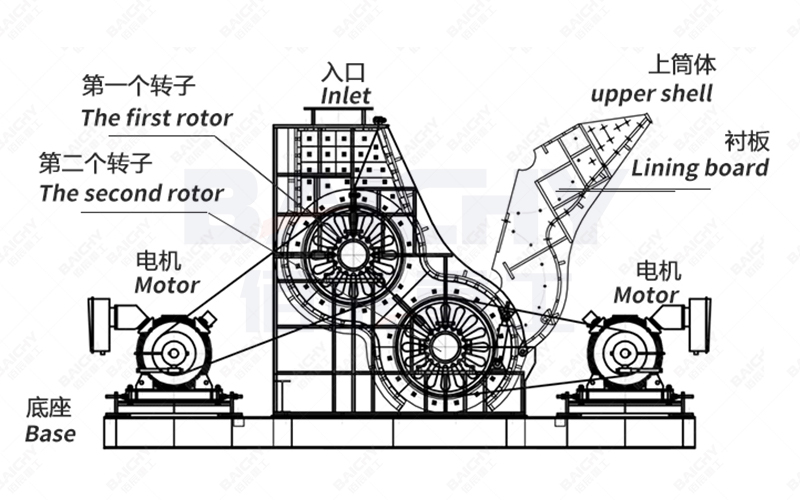

Double Rotor Hammer Crusher

In the mining crushing industry, efficiency and output quality are core pain points. Traditional single-rotor hammer crushers often face problems such as clogging, caking, and efficiency fluctuations when processing high-humidity, high-impurity, or medium-to-high hardness materials.

The emergence of double-rotor hammer crushers represents a structural innovation specifically addressing these industry challenges. It's not simply a matter of adding two rotors; rather, it achieves a qualitative leap in the crushing process through a dual crushing chamber, a stepped crushing process, and synergistic action.

The core of the double-rotor hammer crusher lies in its two parallel rotor systems, each independently driven and equipped with multiple rows of high-strength, heavy-duty hammers. The two rotors rotate in opposite directions.

After the material enters the crushing chamber, it undergoes two stages:

1. Primary crushing zone: The first rotor performs initial impact and tearing of the material.

2. Secondary crushing zone: The pre-crushed material is immediately thrown towards the second counter-rotating rotor for further, even multiple, impacts, collisions, and grinding.

This design essentially creates a continuous, high-intensity collision zone, where the material is repeatedly impacted within the chamber until it reaches the desired particle size and is discharged through the grate openings.

Structural diagram of a double-stage hammer crusher

Why choose our double-rotor hammer crusher?

Based on twenty years of technological accumulation and process improvements, our equipment offers the following significant advantages:

Exceptional processing capacity, doubled output: The double-rotor structure significantly increases the number of impacts per unit time. Compared to single-rotor equipment of the same specifications, processing capacity can be increased by 30%-60%, making it particularly suitable for large-scale production lines.

Uniform output particle size and excellent particle shape: The stepped crushing process ensures thorough crushing of the material, minimizing over-crushing. The finished product is mostly cubic in shape, with a reasonable gradation, meeting the requirements for high-quality aggregates.

Anti-clogging and resistant to sticky and wet materials: The strong airflow generated by the double rotors helps to expel moisture and fine particles. The unique chamber design minimizes the risk of clogging when processing materials with high water and soil content. Strong Adaptability, Multi-purpose Machine: Easily handles medium-to-low hardness materials such as limestone, bluestone, coal gangue, and shale, and can even be used for the recycling and crushing of construction waste, offering a wide range of applications.

Stable Operation, Low Maintenance Costs: The dual-rotor system distributes the load, resulting in more balanced stress on each rotor and more even wear. Key components utilize high-chromium alloy wear-resistant materials and a modular design, ensuring a long service life and easy replacement.

Double-stage hammer crusher customer site

Application Case: Successful Practice Proves Strength

In a renovation project for a large cement group's aggregate production line in North China, we replaced the original two-stage crushing system (jaw crusher + impact crusher) with a single PCZ-1820 dual-rotor hammer crusher.

Material: Medium-hardness limestone, containing a certain amount of clay.

Challenge: The original process was complex and energy-intensive; clay easily caused blockages in the impact crusher during the rainy season.

Result: After the renovation, single-stage crushing was achieved, with a product particle size of ≤80mm, and a stable output of over 800 tons/hour. Electricity consumption was reduced by approximately 25%, and the problem of material blockage was completely solved, significantly improving the customer's overall efficiency.

Recommended Related Equipment

For building an efficient crushing production line, the dual-rotor hammer crusher often serves as the core secondary crushing equipment. We recommend the following high-quality equipment to complement it:

1. Upstream Feeding: Heavy-duty plate feeder (for uniform and stable feeding)

2. Primary Crushing: Jaw crusher (for primary crushing of large materials)

3. Downstream Screening: Circular vibrating screen (for finished product classification and return material separation)

4. Conveying System: Belt conveyor (for connecting the entire process)

Frequently Asked Questions (FAQ)

Q1: Is the power consumption of a dual-rotor hammer crusher much higher than that of a single-rotor crusher?

A1: Not necessarily. Although the absolute value of the driving power increases, due to its extremely high crushing efficiency, the energy consumption per unit output (kWh per ton) is usually lower than traditional equipment, resulting in a better overall energy efficiency ratio.

Q2: Do the hammer heads wear out quickly, and is replacement difficult?

A2: Our hammer heads feature a symmetrical, replaceable design. When one working edge wears out, the other side or end can be used, resulting in high utilization. Replacement only requires opening the inspection door; no other structures need to be disassembled. One person can complete the replacement quickly, making maintenance convenient.

Q3: Does the equipment have strict requirements for the material feed size?

A3: Yes, there are requirements. Generally, the feed size should not exceed 1/3 of the rotor's working diameter (this varies depending on the model). We recommend using a jaw crusher at the front end for primary crushing to ensure efficient and stable operation of this machine and protect the rotor from accidental impact from unbreakable materials (such as iron blocks).

Q4: How is the output particle size controlled?

A4: This is mainly controlled by adjusting the size of the grate bar gaps at the bottom. We provide grate bar assemblies with different gap sizes, allowing customers to select and replace them according to their final product requirements, providing flexible adjustment.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.