Configuration Structure Of The Dryer

The rotary dryer adopts modern advanced scientific drying technology, with reasonable structural design and stable and efficient operation. The whole set of equipment consists of the following core components:

1. Heat source system: Provides stable heat energy and supports multiple fuels such as gas, coal, and biomass.

2. Feeding device: Feeds evenly, prevents blockage, and improves drying efficiency.

3. Belt feeder: Accurately controls the material conveying volume to ensure drying uniformity.

4. Rotary drum: Made of high-quality high-temperature resistant steel, with lifting plates installed inside to enhance heat exchange efficiency.

5. Belt unloader: Automatic discharge, reduce manual intervention, and improve production efficiency.

6. Draft fan: Optimize hot air circulation, reduce energy consumption, and increase drying speed.

7. Dust collector: Efficiently filters dust and meets environmental emission standards.

8. Distribution cabinet: Intelligent control system to achieve automated operation and ensure safe operation of equipment.

Heat source selection for dryer

The heat source of the dryer directly affects the drying efficiency, operating cost and environmental performance. At present, the coal slime dryer mainly uses the following heat source equipment:

1. Gas heating equipment: suitable for natural gas, coke oven gas, etc., with full combustion, high thermal efficiency and excellent environmental performance.

2. Coal-fired heating equipment: economical and affordable, suitable for areas rich in coal resources, and needs to be equipped with a dust removal system to reduce pollution.

3. Biomass heating equipment: using renewable fuels such as straw and sawdust, low-carbon and environmentally friendly, in line with the trend of sustainable development.

4. Steam conversion equipment: suitable for factories with steam supply, stable heat source and low operating cost.

Applicable heat sources include:

✔ Natural gas ✔ Steam ✔ Coke oven gas ✔ Coal gas ✔ Biomass fuel

1200x15000mm dry Technical Parameters

| Spec.(Dia.x Length mm | Volume(m³) | Capacity (t/h) | Gradient(%) | Highest Inlet AirTemperature(℃) | Rotate Speed(r/min) | Main Motor(kw) |

| Φ1500x12000 | 21.2 | 4.5-5.7 | 3-5 | 700~800 | 2~6 | 15 |

Product Description of YGM 130 Grinding Mill

The maximum feed particle size of the YGM high-pressure mill is 35mm, and the diameter of the most significant output particle size is only 30 mesh. The general particle size diameter is 500 mesh, and the smallest particle size can reach 1000 mesh. The maximum production capacity is as high as 2.5-9.5 tons per hour. YGM high-pressure mill has a high-pressure spring pressure device inside, which increases the grinding pressure of the roller by 800-1200kg under the action of the high-pressure spring. Compared with other mills, the production capacity under the same power condition is also increased. 20-30%. The grinding roller device in the YGM high-pressure mill adopts overlapping multi-stage seals, which have good sealing performance and the dust removal effect fully meets the national dust emission standards. An excellent environmental protection effect has been achieved.

130YGM Grinding Mill Technical Parameters

| Number of rollers | 5 |

| Roller size | 410×230mm |

| Maximum Feed Size | 30mm |

| Finished product size | 30-500 mesh, some can reach 1000 mesh |

| Capacity | 2.5-9.5t/h |

| Monitor rate | 75kw |

| Fan power | 75kw |

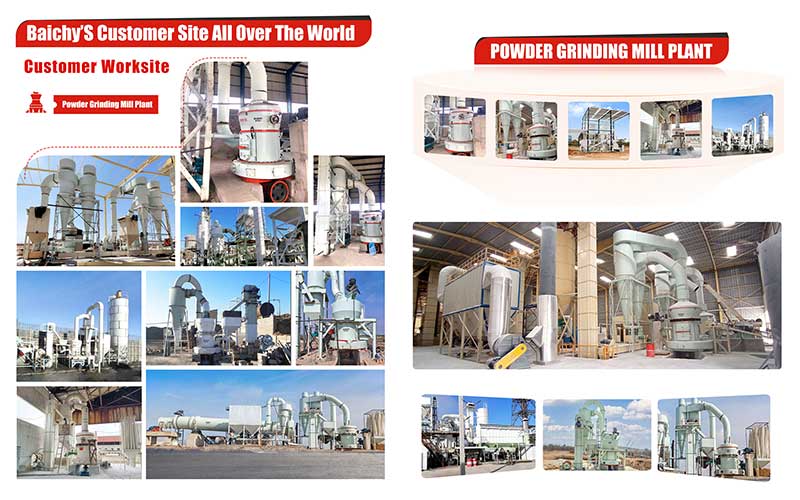

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)