When mining or building materials companies enter the equipment selection phase, the configuration of the crushing system always puts immense pressure on decision-makers. Faced with equipment investments often reaching millions, should they choose the simple jaw crusher or the technologically advanced cone crusher? What is the actual difference in their return on investment?

This article will break away from the general discussions of traditional equipment comparisons and provide a practical selection methodology through a systematic analysis of five key indicators. Whether you are a novice in equipment procurement or an experienced project manager, you can gain useful decision-making support from this article.

I. Basic Understanding: Equipment Principles and Positioning

1.1 Jaw Crusher (Jaw Crusher): A Pioneer in Coarse Crushing

PE Jaw Crusher

Working Principle: The jaw crusher uses the most direct compression crushing principle. Through the periodic relative movement of the moving jaw and the fixed jaw, it simulates the chewing action of an animal to crush materials. This simple and direct working method makes it a classic design in the crushing field.

Equipment Positioning: As the first line of defense in the crushing production line, the jaw crusher is specifically designed to handle large pieces of raw material directly transported from the mining face. Its powerful throughput capacity makes it irreplaceable in the coarse crushing stage.

Applicable Scenarios: Particularly suitable for processing raw ore and rock with a particle size exceeding 500mm, performing excellently in primary crushing in mines and pre-processing of construction waste.

1.2 Cone Crusher (Cone Breaker): The Fine Processing Expert for Medium and Fine Crushing

Hydraulic Cone Crusher

Working Principle: The cone crusher uses the principle of layered crushing. Material is continuously subjected to compression, grinding, and impact within the annular crushing chamber formed by the moving and fixed cones. This multi-dimensional force distribution makes it significantly efficient in the fine crushing stage.

Equipment Positioning: Typically used as a secondary or tertiary crushing unit in a production line, responsible for further processing the material coarsely crushed by the jaw crusher to the required finished particle size.

Applicable Scenarios: Particularly suitable for the fine crushing of high-hardness materials (such as granite and basalt), and for the production of commercial concrete aggregates with high requirements for finished particle shape.

1.3 A Simple Distinction

A jaw crusher is like a rugged strongman, responsible for crushing boulders into smaller pieces; a cone crusher is like a delicate sculptor, grinding the stones into aggregate that meets the required specifications. The two work more in synergy than as simple substitutes.

II. Detailed Explanation of 5 Core Selection Criteria

Criterion 1: Material Hardness and Abrasiveness ⭐⭐⭐⭐⭐

Technical Comparison Analysis:

| Dimension | Jaw Crusher | Cone Crusher |

| High Hardness Materials (Granite, Basalt, Quartzite) | ✅ Can be processed, but wears out quickly | ✅✅ Laminated crushing, excellent wear resistance |

| Medium-Low Hardness Materials (Limestone, Coal Gangue) | ✅✅ Economical and efficient | ⚠️ Underutilization of resources, high cost |

| Highly abrasive materials | Jaw plates wear out quickly | mantle is more durable |

Selection Recommendations:

• When the material's Mohs hardness is >5, the cone crusher has a significant wear resistance advantage in the medium and fine crushing stages, resulting in lower total lifespan costs.

• For materials with high abrasiveness, the mantle life of a cone crusher is typically 2-3 times that of a jaw crusher's jaw plates.

• For medium-low hardness materials (such as limestone), a jaw crusher is more economical, avoiding waste due to over-configuration.

Criterion 2: Feed Size and Capacity Requirements ⭐⭐⭐⭐⭐

Technical Parameter Comparison:

| Parameters | Jaw Crusher | Cone Crusher |

| Maximum Feed Size | Up to 1200mm+ | Typically <300mm (requires primary crushing) |

| Discharge Size Range | 10-300mm | 3-64mm (fine crushing type can handle even finer materials) |

| Capacity Characteristics | High throughput in primary crushing | High efficiency in fine crushing, low unit energy consumption |

Selection Recommendations:

• When raw material particle size > 500mm, a jaw crusher is the only choice; a cone crusher cannot directly process large materials.

• When producing 0-5mm manufactured sand, a combination of a cone crusher and a vertical shaft impact crusher is the best choice.

• For large projects with single-line capacity requirements > 500t/h, a multi-cylinder hydraulic cone crusher has significant advantages in stability and energy consumption.

Indicator 3: Finished Product Particle Shape and Grading Requirements ⭐⭐⭐⭐

Particle Shape Quality Analysis:

• Jaw Crusher Finished Product Characteristics: Due to its simple compression crushing mechanism, the finished product has a high content of needle-like and flaky particles (approximately 15-20%), with distinct angular edges but poor regularity.

• Cone Crusher Finished Product Characteristics: The layered crushing principle subjects the material to multiple forces within the chamber, resulting in a high cubic content (>90%) and good gradation continuity.

Key Application Scenarios:

• High-standard concrete aggregate (highway, high-speed rail projects): Strict restrictions on needle-like and flaky particle content (usually <10%) make the cone crusher the obvious choice.

• Asphalt concrete aggregate: Highly sensitive to particle shape; cone crushers are recommended to ensure pavement quality.

• Ordinary building backfill and subgrade materials: Particle shape requirements are not high; jaw crusher finished products are perfectly acceptable and cost-effective.

Indicator 4: Investment Costs and Operating Expenses ⭐⭐⭐⭐

In-depth Cost Structure Analysis:

Initial Investment Comparison

• Jaw Crusher Advantages: Relatively simple mechanical structure; equipment price is typically only 30-50% of a cone crusher for the same capacity.

• Cone Crusher Characteristics: Complex hydraulic system and automatic control, higher unit price, but better automation and safety.

Detailed Comparison of Operating Costs

| Cost Items | Jaw Crusher | Cone Crusher |

| Lifespan of Wear Parts | Jaw Plate: Approx. 3-6 months | Jaw Wall: Approx. 6-12 months |

| Unit Energy Consumption | Lower in coarse crushing stage | Better energy efficiency in fine crushing stage |

| Labor Costs | Requires frequent manual adjustment of discharge opening | Hydraulic automatic adjustment, one person can manage multiple units |

| Maintenance Complexity | Simple maintenance, low technical threshold | Requires a professional hydraulic system maintenance team |

TCO (Total Cost of Ownership) Analysis:

• Short-term projects under 3 years: Jaw crushers have a significant initial investment advantage, suitable for situations with tight funds or short project cycles.

• Long-term operation over 5 years: Although cone crushers have a higher initial investment, low maintenance costs and long lifespan of wear parts can allow the total cost to surpass that of jaw crushers within 2-3 years.

Indicator 5: Operating Environment and Space Limitations ⭐⭐⭐

Site Advantages of Jaw Crusher:

• Compact structure, low installation height, and small space requirements for the plant.

• Particularly suitable for mobile crushing plants (wheel-mounted/tracked), offering flexible and convenient relocation.

• Relatively simple foundation requirements, allowing for rapid installation and commissioning.

Space considerations for cone crushers:

• Relatively high equipment height, requiring a feed buffer silo and supporting foundation.

• Primarily used in fixed production lines; mobile versions are more expensive.

• Multi-cylinder hydraulic models require additional consideration of hydraulic station layout and pipeline space.

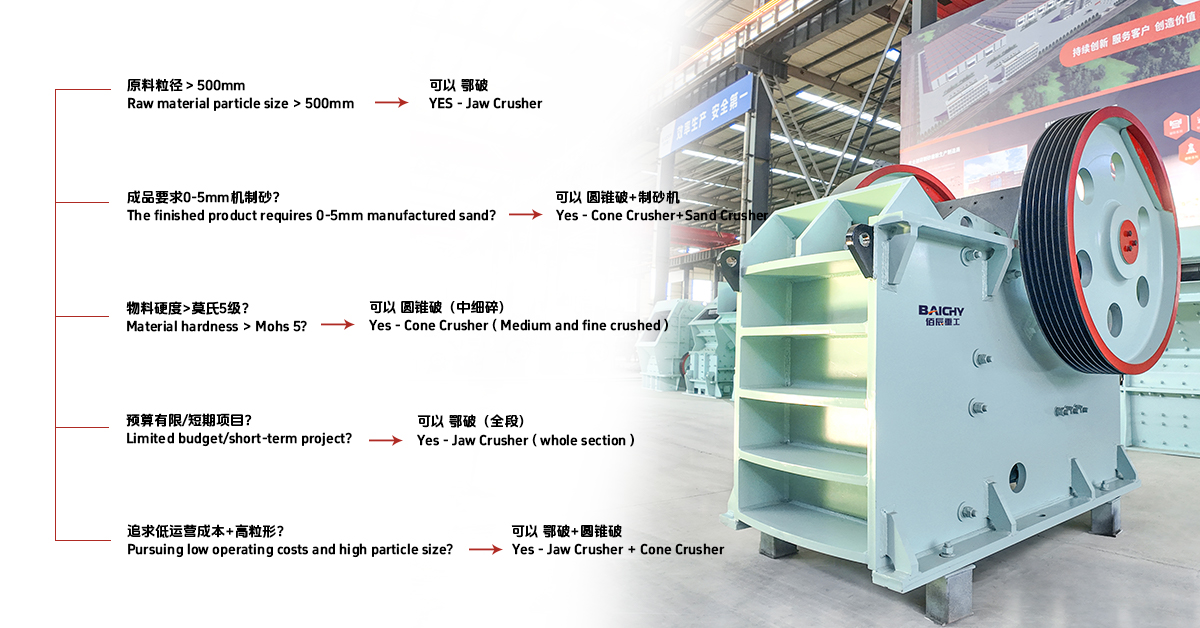

III. Typical Application Scenarios Decision Tree

Application scenarios of jaw crushers and cone crushers

IV. Common Selection Misconceptions and Avoidance Guidelines

❌ Misconception 1: Cone crushers can completely replace jaw crushers.

Truth Analysis: This is the most common misconception. Cone crushers have limited feed size (usually <300mm). Directly feeding large pieces of raw material into a cone crusher can lead to stalling, overload protection shutdown, and severely impact equipment lifespan and production efficiency. The correct approach is to use a stepped configuration of jaw crusher for coarse crushing + cone crusher for medium and fine crushing.

❌ Myth 2: Focusing only on unit price, ignoring the cost of wearing parts

The truth about cost: When choosing equipment for crushing highly abrasive materials, many users only compare the purchase price. In reality, when crushing hard rocks like granite, the jaw plates of a jaw crusher may need replacement every 3 months, while the jaw walls of a cone crusher can last for over a year. In the long run, the cost of wearing parts and downtime losses may far exceed the price difference in equipment.

❌ Myth 3: Blindly pursuing high speed/high capacity

The truth about technology: Cone crushers require a full-cavity feed to fully utilize the advantages of laminar flow crushing. Insufficient or intermittent feeding will lead to insufficient material density in the crushing chamber, increasing the content of needle-like and flaky particles, reducing product quality and equipment efficiency.

❌ Myth 4: Ignoring the matching of feeding equipment

Systematic thinking: Cone crushers have extremely high requirements for feed uniformity and require a suitable vibrating feeder and iron removal device. Many users invest in high-performance cone crushers but are stingy with investment in feeding equipment, resulting in the system's capacity not being fully utilized.

V. Summary: Selection Quick Reference Table

| Your Needs | Recommended Choice | Key Reasons |

| Large Ore Coarse Crushing (>500mm) | Jaw Crusher (Required) | The only equipment capable of directly processing large materials |

| Medium and Fine Crushing of High-Hardness Materials | Cone Crusher (Preferred) | Good wear resistance, low cost per ton |

| Limited Budget, Simple Crushing | Jaw Crusher (Economy Model) | Low investment, simple maintenance |

| Concrete Aggregate, High Particle Shape Requirements | Cone Crusher (Cubic Finished Product) | Needle-like and flaky content <10% |

| Mobile Crushing, Frequent Relocation | Jaw Crusher Mobile Station (More Flexible) | Quick relocation, strong adaptability |

| Long-Term Operation, Pursuing Low TCO | Cone Crusher (Superior Overall Cost) | Lowest Total Cost Over 5 Years |

| Complete Crushing Production Line | Jaw Crusher + Cone Crusher Combination (Classic Configuration) | Complementary Advantages, Optimal System |

In choosing between cone crushers and jaw crushers, there is no absolutely better equipment, only the more suitable solution. It is recommended to establish a comprehensive evaluation system based on three dimensions: raw material characteristics, production capacity requirements, and investment budget. If necessary, consult professional manufacturers for customized solution design. Correct equipment selection is the cornerstone of project success and deserves sufficient effort and resources for scientific decision-making.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!