What is a small mobile crushing station?

A small mobile crushing station is a mobile stone crushing equipment that integrates feeding, crushing, screening and conveying. It is suitable for scenes such as construction waste treatment, mining crushing, and road construction. Compared with traditional fixed crushers, it has the advantages of flexible transfer, rapid production, environmental protection and energy saving, and is particularly suitable for small and medium-sized engineering projects or frequent changes in work sites.

Second, the core advantages of small mobile crushing stations

✅ Strong mobility-adopting tire or crawler drive, no fixed foundation is required, and it can be quickly transferred to work.

✅ Energy saving and environmental protection-equipped with noise reduction and dust removal systems, in line with environmental protection requirements, reduce dust pollution.

✅ One machine for multiple uses-can be matched with a variety of crushing hosts such as jaw crusher, impact crusher, cone crusher, etc., to adapt to different materials (such as concrete, rock, construction waste).

✅ Lower cost-compared with fixed production lines, it has small investment and simple maintenance, suitable for small and medium-sized enterprises and individual contractors.

3. Application scenarios of small mobile crushing stations

Construction waste recycling-crushing concrete, bricks, asphalt, and realizing resource recycling.

Mine crushed stone-processing limestone, granite, pebbles, etc., to produce aggregates of different specifications.

Road construction-crushing roadbed materials on site to reduce transportation costs.

Urban transformation-flexible operation in narrow sites to reduce the impact on the surrounding environment.

4. How to choose a suitable small mobile crushing station?

1. Select by driving mode

Tire-type mobile crushing station: suitable for short-distance transfer, relying on traction head, economical and affordable.

Crawler mobile crushing station: fully hydraulically driven, adaptable to complex terrain, with a high degree of automation.

2. Select by crushing machine

Crushing machine type Applicable materials Output size Features

Jaw crusher Hard rock, construction waste 10-350mm Large crushing ratio, wear resistance

Impact crusher Medium hardness stone 5-60mm Good finished product particle shape, suitable for sand making

Cone crusher High hardness ore 3-64mm Stable operation, long life

3. Select by output demand

Small (10-50 tons/hour): Suitable for individual contractors and small quarries.

Medium (50-150 tons/hour): Suitable for construction waste treatment stations and medium-sized mines.

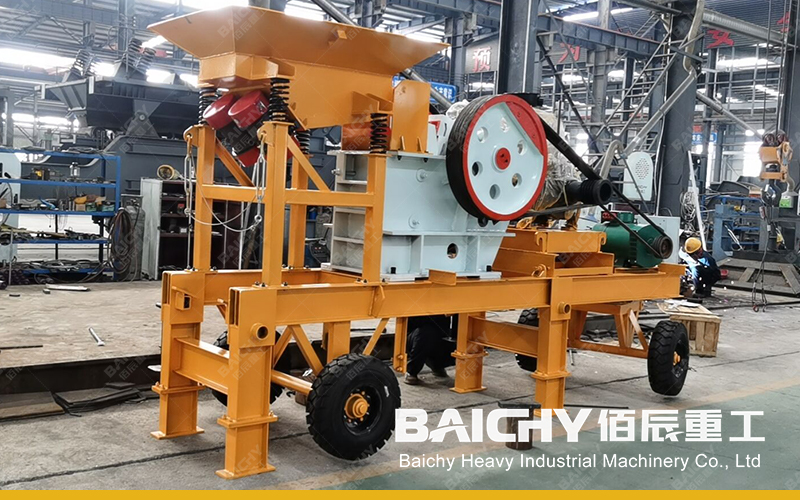

5. Baichy Heavy Industry Small Mobile Crushing Station - Factory Direct Sales, Quality Assurance

🔹 10+ years of industry experience, providing customized solutions

🔹 Direct sales at factory prices, no price difference from middlemen, saving 30% of costs

🔹 National after-sales support, 24-hour technical response

Consult now: 0086 15093222637

Official website: www.baichychina.com

VI. Frequently Asked Questions (FAQ)

Q1: What is the price of a small mobile crushing station?

A: Depending on the configuration, the price is between 200,000-1 million. Please consult the manufacturer for a quote.

Q2: Can a small mobile crushing station be rented?

A: Support short-term rental, suitable for temporary engineering needs, please contact customer service for details.

Q3: Is the equipment maintenance complicated?

A: Modular design, key components are easy to replace, and operation training is provided to reduce maintenance difficulty.

Small mobile crushing stations are becoming the preferred equipment for construction waste treatment and mine crushing due to their flexibility, efficiency and low cost. If you are looking for a mobile crushing solution with high cost performance and strong adaptability, please contact XX Machinery. We will provide you with professional products and services!

Consult now and enjoy free on-site inspection + solution customization!