In stone crushing production in industries such as mining, building materials, transportation, and energy, impact crushers, as an important secondary crushing equipment, have become a key choice for many users to improve product quality and efficiency due to their unique crushing principle and significant technological advantages. Working in conjunction with primary coarse crushing equipment such as jaw crushers, they together form a highly efficient and energy-saving modern crushing production line.

I. Impact Crusher vs. Jaw Crusher: Positioning and pision of Labor

First, it is important to clarify that jaw crushers and impact crushers play different roles in the crushing process; they are complementary rather than substitutive.

• Jaw Crusher (Coarse Crushing Equipment): As the "pioneer" of the production line, it is mainly responsible for the first stage of coarse crushing of large raw materials. Its structure is robust, and it excels at handling large-sized, high-hardness raw stones, but its output particle size is usually uneven, with many sharp edges.

• Impact Crusher (Medium and Fine Crushing Equipment): As a secondary crushing equipment, it receives products from jaw crushers or other coarse crushing equipment. Its core value lies in "shaping." Utilizing the impact crushing principle of "stone-on-stone" or "stone-on-iron," it effectively crushes particles into cubic shapes, resulting in a final product with uniform particle size and reasonable gradation, significantly enhancing its market value.

Simply put: the jaw crusher handles the "breaking down," while the impact crusher handles the "finishing."

II. Six Core Advantages of Choosing an Impact Crusher

1. Excellent Product Particle Shape and High Value

The biggest advantage of the impact crusher is that its crushed product is predominantly a regular cubic shape with extremely low needle-like and flaky content. This particle shape is a mandatory requirement in high-standard applications such as high-grade highway surface materials and commercial concrete mixing plants, significantly increasing the selling price of aggregates.

2. Flexible and Adjustable Discharge Particle Size, Wide Application

The equipment can flexibly and extensively control the discharge particle size by adjusting the rotor speed and the gap between the impact plates, meeting the perse needs of different customers for finished product specifications and achieving "one machine for multiple uses."

3. Strong Wet Material Handling Capacity, No Clogging

Compared to other types of crushers, impact crushers perform better when handling materials with high moisture content. Their design effectively reduces material adhesion within the crushing chamber, thus preventing discharge port blockage and ensuring continuous and stable production line operation.

4. High Crushing Ratio, Simplified Process

Impact crushers have a high crushing ratio, sometimes replacing two-stage crushing processes, simplifying production and reducing equipment investment costs.

5. Durable Wear-Resistant Parts, Low Maintenance Costs

Taking Baichy Machinery's impact crushers as an example, their core components (such as hammers, rotors, and liners) are made of high-chromium cast iron, multi-alloy steel, and ultra-high manganese steel, resulting in high wear resistance and a long service life. Simultaneously, parts are easy to replace, and metal utilization is high, significantly reducing long-term maintenance costs and downtime.

6. Wide Range of Applications

Effectively crushes various medium-hard and below brittle materials with a compressive strength not exceeding 350MPa and a side length less than 500mm, such as limestone, granite, concrete, coal, quartz, and gypsum. Its applications are extremely wide-ranging.

III. Baichy Impact Crusher: Building Core Competitiveness Through Material and Craftsmanship

Baichy Machinery deeply understands the principle that "to do a good job, one must first sharpen one's tools." Our advantage lies not only in the overall machine design but also in the pursuit of the highest quality materials for core components:

• Customized Wear-Resistant Solutions: Based on the different characteristics of the materials being crushed (such as hardness and corrosiveness), we match the most suitable hammer and liner materials for users, from high-chromium cast iron to multi-alloy steels, ensuring the longest service life and best economic benefits under specific working conditions.

• Free Customization Service: In addition to core components, we also offer free customization services for the equipment's color, markings, and other appearance, making the equipment a unique symbol representing your company image.

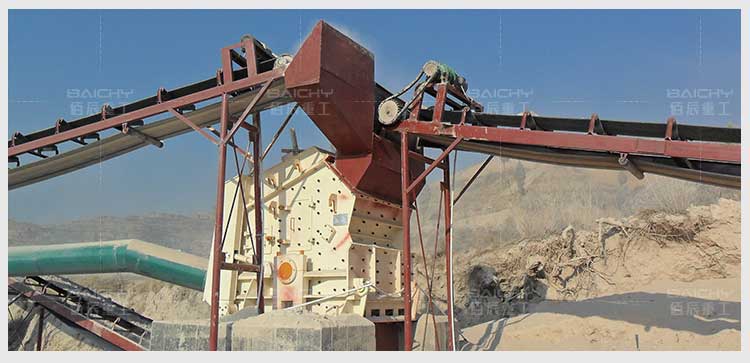

Case Study: As shown in the image, we have just completed the production and testing of two sets of PF1007 and PF1010 impact crushers, which are about to be shipped to our customer's site in Indonesia. This fully demonstrates the competitiveness and recognition of Bestch equipment in the international market.

Choosing an impact crusher is not just choosing a piece of equipment, but choosing a solution that can enhance product added value, optimize production line efficiency, and reduce overall operating costs. Whether used for shaping sand and gravel aggregates or for fine crushing medium-hard materials, impact crushers demonstrate their irreplaceable value.

If you are looking for a high-efficiency, reliable, and high-quality secondary crushing equipment, Bestch impact crushers are your ideal choice. Contact us for a customized equipment quote and technical solutions!