In the sand and gravel aggregate industry, achieving efficient, energy-saving, and environmentally friendly crushing while precisely controlling the finished particle size (40mm, 20mm, and 10mm) is a core concern for many companies. Leveraging years of technological expertise, Baichy Heavy Industry has launched a 200tph (tons per hour) aggregate crushing system solution to help companies increase production capacity, reduce energy consumption, and meet their high-quality aggregate production needs.

Process Design: Three-Stage, One Closed Circuit, Precise Classification

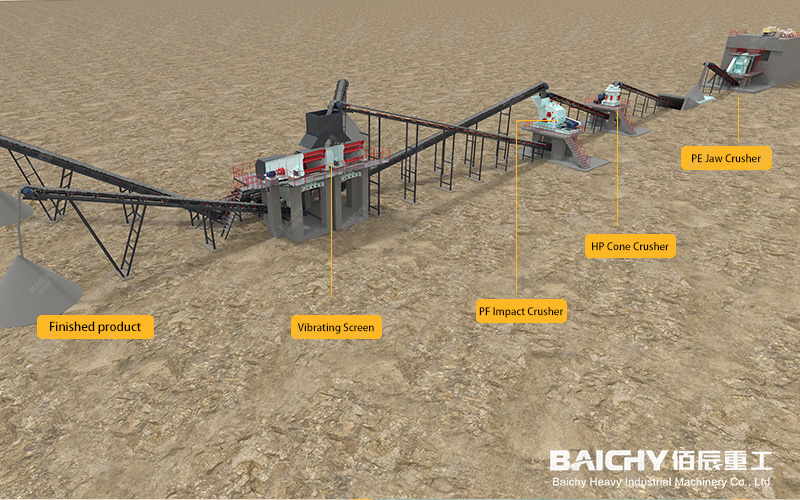

For aggregate crushing needs up to 200 t/h, Baichy Heavy Industry recommends a "three-stage, one closed circuit" crushing system to ensure efficient crushing and precise screening:

1. Coarse Crushing: Jaw Crusher (JC110) - Initially crushes bulky raw materials to ≤150 mm

2. Secondary Crushing: Cone Crusher (HPT300) - 45% of 40 mm aggregate

3. Fine Crushing: Impact Crusher (VSI6X1263) - Optimizes particle shape, with 10-20 mm aggregate accounting for 60%

4. Closed Circuit Screening: 3YK3072 vibrating screen (three-layer screen) achieves precise classification of 40 mm, 20 mm, and 10 mm

Advantages:

✔ High pass rate: 90% of raw materials pass the first crushing step

✔ Low return rate: Closed-circuit design reduces over-crushing

Flexible Adjustment: Adjustable screens adapt to different market demands.

Core Equipment Configuration: Highly Efficient, Energy-Saving, Stable and Reliable.

Jaw Crusher (C110)

• Processing Capacity: 200-250tph

• Discharge Adjustment: 80-180mm, accommodating materials of varying hardness.

Cone Crusher (HP300)

• Hydraulically adjustable discharge opening (25-45mm) ensures high yield of 40mm aggregate.

Vertical Shaft Impact Crusher (VSI8518)

• Fine crushing and shaping, achieving a flake content of less than 8%, improving aggregate quality.

Vibration Screening System

• Three-layer screens (45mm/22mm/12mm) for precise grading.

• Automatic return of returned material to the cone crusher, improving system efficiency.

Core System Advantages: Energy-Saving, Environmentally Friendly, Intelligent.

• Low Energy Consumption: ≤1.8kWh per ton; frequency conversion technology saves 15% energy. Environmentally Friendly: Fully enclosed design + pulse dust removal, emissions <20mg/m³

Intelligent (optional):

• Online particle size monitoring, automatic discharge adjustment

• Remote monitoring, real-time monitoring of production status

Case Application and Benefit Analysis

Application Results at a Large-Scale Andesite Sand and Gravel Plant in Indonesia:

• Production Capacity: Stable ≥200tph, 8,000 operating hours per year

• Finished Product Qualification Rate: ≥95% (Compliant with GB/T 14685-2022 Standard)

• Economic Benefits: Compared to traditional production lines, energy consumption is reduced by 20% and maintenance costs by 30%.

Amid the high-quality development of the sand and gravel industry, Baichy Heavy Industry's 200tph aggregate crushing system, with its high efficiency, energy-saving, and intelligent features, is an ideal choice for medium- and large-scale sand and gravel companies. For customized solutions or technical consultation, please contact Baichy Heavy Industry and we will provide you with professional support!

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)