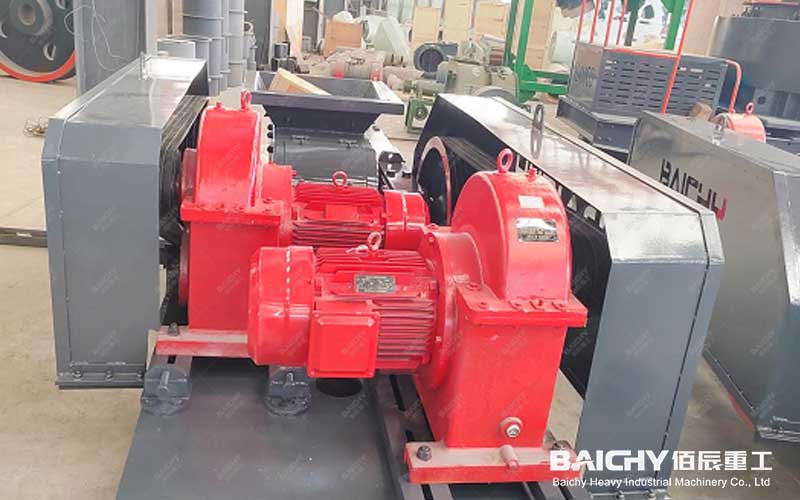

In medium and fine crushing operations in mining, building materials, and chemical industries, double-roll crushers have established a niche market due to their simple structure, reliable operation, and low over-crushing rate. Today, we'll focus on a classic small- to medium-sized machine—the 2PG60x400 double-roll crusher—and provide a comprehensive inside-and-out analysis.

I. Model Explanation: Understanding the "2PG60x400" Naming Convention

The "2PG600x400" model itself provides a concise technical description:

• 2PG: Stands for "Double-Roll Crusher."

• 600: Refers to the roller diameter of 600 mm.

• 400: Refers to the effective working length of the rollers of 400 mm.

Thus, this is a double-roll crusher with rollers measuring φ600 × 400 mm. Its compact design is ideal for small and medium-capacity crushing lines.

II. Core Advantages: Why Choose the 2PG60x400 Double-Roll Crusher?

1. Uniform and Controllable Output Particle Size: By simply adjusting the gap between the two rollers, the output particle size can be precisely controlled (typically between 2-10mm), effectively reducing over-crushing and increasing product value.

2. Simple Structure and Low Maintenance Cost: The mechanical structure is simple, with a low failure rate and easy operation. Routine maintenance and replacement costs for wearing parts (such as roller skins) are relatively low.

3. Versatile Application: It can be used for medium and fine crushing of medium- and low-hardness ores (such as coal, limestone, and gypsum). With proper adjustment, it can also be used for sand production, producing sand and gravel with excellent particle shape.

4. Reliable Overload Protection: The equipment is typically equipped with a spring or hydraulic overload protection device. If uncrushable objects (such as iron blocks) enter, the rollers automatically retract to expel the foreign matter, protecting the main unit from damage.

III. Technical Parameters Overview (Reference Standard Model)

| Parameter Name | Value/Description |

| Roller Dimensions (Diameter × Length) | 600 mm × 400 mm |

| Maximum Feed Size | ≤ 30 mm |

| Discharge Opening Adjustment Range | 2 - 10 mm |

| Processing Capacity | 5 - 15 t/h (Varies depending on material properties and discharge size) |

| Motor Power | 2 × 7.5 kW or 2 × 11 kW (Dual Motor Drive) |

| Weight | Approximately 1.5 tons (Varies slightly depending on manufacturer design) |

IV. Main Applications

• Mining Crushing: Suitable for secondary crushing (medium and fine crushing) of ores with a hardness below medium, such as coal, limestone, gypsum, and coke.

• Building Material Sand Making: Ideal for small sand production lines, especially for materials such as pebbles and river stones, providing excellent sand shaping.

• Metallurgy and Chemical Industry: Suitable for crushing raw materials such as sintered ore, coal, and slag.

V. Purchasing and Usage Guide

When considering the 2PG60x400 double-roll crusher, please pay attention to the following points:

1. Material Compatibility: This equipment is most suitable for low- to medium-hardness materials with a compressive strength of ≤160 MPa. High-hardness, highly abrasive materials can lead to increased roller wear, increasing production costs.

2. Core Component Material: Be sure to inquire with the manufacturer about the material used for the roller (wear-resistant liner). Wear-resistant materials such as high-manganese steel or high-chromium alloy steel are preferred, as this directly impacts the equipment's service life.

3. Manufacturer Competence and After-Sales Service: Choose a reputable manufacturer to ensure comprehensive technical support, installation guidance, and timely supply of wear parts.

The 2PG60x400 double-roll crusher, with its moderate specifications, stable performance, and wide applicability, is an ideal choice for many small and medium-sized crushing projects. A thorough understanding of its characteristics and appropriate selection will ensure significant economic benefits for your production.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)