A customer from Congo found us through a foreign trade company in Guangdong and wanted to build a 100tph stone production line.

The customer was not very familiar with the equipment but learned that the material crushed by the crushing plant was limestone. We made a plan for the limestone crushing production line:

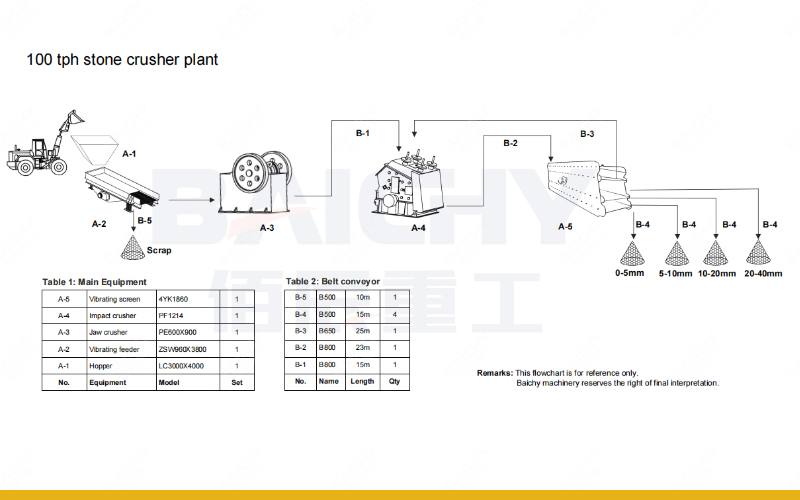

For the 100tph limestone crushing production line plan, we can elaborate on the equipment configuration, production process flow, and performance characteristics. The following is an example of a plan that integrates information from multiple sources:

100tph limestone crushing production equipment configuration

• Vibrating feeder: used to feed the raw limestone material into the crusher evenly and continuously. According to the specific needs of the production line, you can choose a suitable model, such as ZSW9638 Vibrating feeder;

• Jaw crusher: As primary crushing equipment, the jaw crusher can crush large pieces of limestone into smaller particles. For a 100tph production line, you can choose models such as PE-600x900 jaw crusher or PE-500x750 jaw crusher, which have the advantages of high hourly output, large crushing ratio, and easy maintenance.

• Secondary crushing equipment: According to the hardness of the limestone and the particle size requirements of the finished product, you can choose a cone crusher or an impact crusher as the secondary crushing equipment. For example, for limestone with higher hardness, you can choose a 1200 cone crusher; for limestone with moderate hardness, you can choose a PF1214 impact crusher or an HP300 cone crusher. These devices can further crush the material and achieve the required finished particle size.

• Vibrating screen: used to screen the crushed material and separate stones of different specifications. According to production needs, you can choose models such as 1854 vibrating screen, 3YK1545 vibrating screen, or 4YK1545 vibrating screen.

• Belt conveyor: responsible for transporting and transferring materials between various equipment. According to the specific layout and needs of the production line, multiple conveyors of different lengths can be configured, such as B50010m, B50015m, B800*22m, etc.

• Centralized electronic control system: Centrally control and monitor the entire production line to ensure the safe and stable operation of the equipment.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.