Coarse aggregates ranging from 19 to 37.5 mm are the "backbone" materials for structural concrete, roadbed paving, and railway ballast. The quality of their particle shape and the accuracy of their gradation directly affect the quality and safety of engineering projects.

Achieving efficient and large-scale production of aggregates within this specific particle size range is not possible with a single piece of equipment, but rather the result of a coordinated operation of crushing and screening equipment.

Stone Crushing Plant PDF, Download ↓↓↓

This article will delve into the core equipment in the production line and its role.

I. Core Production Equipment: The "Golden Combination" of Crushing and Screening

A single piece of equipment can hardly directly "discharge" aggregates that perfectly meet the gradation requirements. The real key lies in the linked system of "crushing + screening."

1. Crushing Equipment: The Core of Particle Size Shaping

• Jaw Crusher (Coarse Crushing Stage)

◦ Role: The "vanguard" of the production line. Primarily responsible for the primary (coarse) crushing of large raw materials.

• Key Role: Although it doesn't directly produce aggregates with a precise 19-37.5mm particle size, its output particle size determines the efficiency of subsequent processes and the quality of the finished product. By adjusting the discharge port size, it can provide raw materials of ideal size for medium crushing equipment, which is the foundation for subsequent precision crushing.

• Cone Crusher / Impact Crusher (Medium and Fine Crushing Stage)

• Role Positioning: The "main force" of the production line, responsible for precise particle size shaping.

• Advantages of Cone Crusher: Layered crushing principle, large crushing ratio, high degree of automation, and easy control of output particle size. Especially suitable for crushing high-hardness materials, and can stably and efficiently produce coarse aggregates with excellent particle shape (19-37.5mm).

• Advantages of Impact Crusher: Impact crushing principle, the finished product has a more cubic particle shape and better quality. By adjusting the gap between the hammer and the impact plate, it can also effectively crush medium-hard materials and produce aggregates that meet the requirements.

2. Screening Equipment: The "Commander" of Precise Grading

• Vibrating Screen (Grading Screen)

◦ Role: The "quality inspector" of the production line. This is the most indispensable key equipment for separating and obtaining coarse aggregates of 19-37.5mm.

◦ Core Function: The crushed mixed aggregates pass through the vibrating screen, where the equipment precisely grades them according to preset screen sizes (e.g., multi-layer screens of 19mm, 26.5mm, 31.5mm, and 37.5mm). Aggregates that meet the particle size requirements are screened out, while oversized aggregates are returned to the crusher for further crushing.

II. Classic Production Line Flow: The Journey from Raw Material to Finished Product

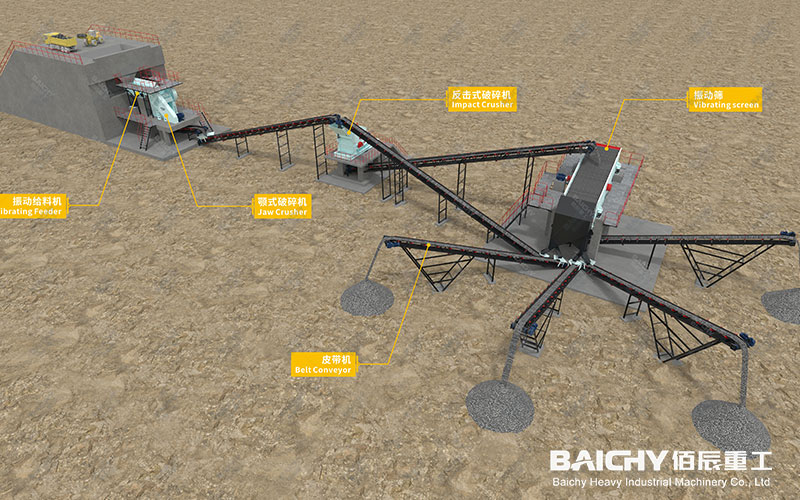

An efficient production line is an organic combination of the above equipment.

A typical flow is as follows:

1. Feeding and Coarse Crushing: The raw material is evenly fed into the jaw crusher by a vibrating feeder for primary crushing.

2. Secondary Crushing and Shaping: The coarsely crushed material is conveyed by a belt conveyor to a cone crusher or impact crusher for secondary crushing to achieve a particle size close to the target range.

3. Screening and Grading: The crushed mixture is conveyed to a vibrating screen.

4. Finished Product Output: The vibrating screen precisely screens out 19-37.5mm finished coarse aggregate, which is directly conveyed to the finished product stockpile.

5. Circulating Crushing: Aggregates with excessively large particle sizes are returned to the secondary crushing equipment for closed-loop circulating crushing until the required size is achieved.

Producing 19-37.5mm coarse aggregate is a complex process. Jaw crushers are fundamental, cone crushers/impact crushers are crucial, and vibrating screens are the core component ensuring the precision of the finished product. Equipment selection and production line configuration heavily depend on raw material characteristics (hardness, moisture content, etc.) and production capacity requirements.