Portable Jaw Crusher, 2026 Rock Crusher, Mobile Crushing Equipment

As a mining crushing equipment manufacturer with 20 years of experience, we closely monitor industry technological trends and market demand changes. The theme Jaw Crusher - Portable Rock Crusher 2026 not only reflects the evolution of equipment design but also reveals three major development directions for the future mining crushing industry: mobility, intelligence, and environmental friendliness. 2026 is expected to be a turning point for the large-scale application of this technology, driving a fundamental transformation of traditional crushing operations.

Overview: Technological Evolution of Portable Jaw Crushers

Building on the high-efficiency crushing capabilities of traditional jaw crushers, portable jaw crushers integrate a mobile chassis, intelligent control system, and modular design, enabling rapid relocation, flexible deployment, and efficient operation. The new generation of equipment in 2026 will achieve breakthroughs in the following areas:

- Enhanced Mobility: More compact structural design reduces transportation limitations.

- persified Energy Sources: Pure electric, hybrid, and traditional power options will be available.

- Intelligent Control: IoT integration and remote monitoring will become standard features.

- Improved Environmental Standards: Dust and noise control will reach new heights.

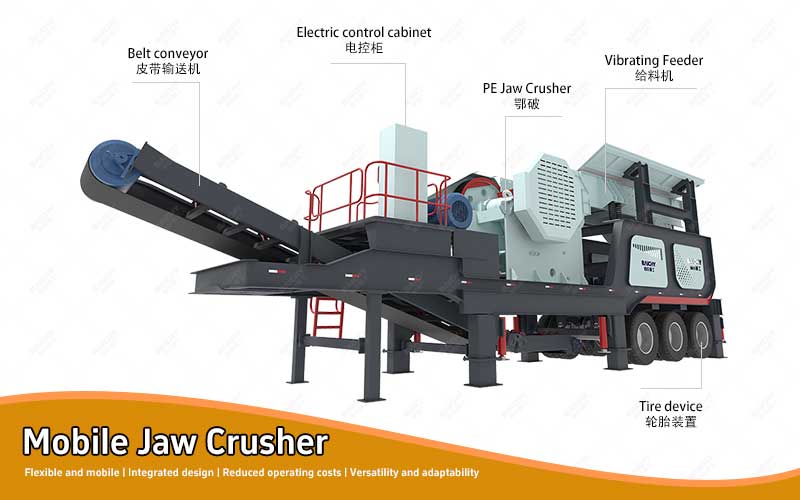

Structural diagram of a mobile jaw crusher plant

Core Advantages: Why Choose the 2026 Portable Equipment?

1. Excellent Operational Flexibility

Portable jaw crushers do not require fixed infrastructure and can be quickly deployed in various scenarios such as mines, construction sites, and road projects, making them particularly suitable for dispersed, phased, or short-term crushing projects.

2. Significant Operating Cost Savings

Reduced material transportation distances lower handling costs; rapid relocation shortens project cycles; modular design reduces maintenance downtime, resulting in a 30-40% reduction in overall operating costs compared to traditional fixed crushing lines.

3. Leading Environmental Compliance

The 2026 equipment will meet stricter environmental regulations, equipped with advanced dust removal systems, noise suppression technology, and emission control devices, helping customers successfully pass environmental impact assessments.

4. Intelligent Operation Management

Integrated sensors monitor equipment status, production data, and wear conditions in real time, enabling predictive maintenance, production optimization, and remote troubleshooting through a cloud platform.

Mobile jaw crusher plant at a customer's site.

Application Cases: Value Demonstration in Real-World Scenarios

Case 1: Mountain Highway Construction Project

A mountain highway project required processing scattered rock obstacles along the route. Using our portable jaw crusher, the equipment moved with the project progress, allowing for on-site crushing and utilization, saving approximately 45% in transportation costs and shortening the project duration by 3 months.

Case 2: Urban Construction Waste Recycling

In urban renewal projects, portable equipment directly processes construction concrete at demolition sites, producing recycled aggregates for new project construction, achieving a zero transportation, zero waste green construction model.

Recommended Equipment

1. PEY Series Hydraulic Portable Jaw Crusher: Patented hydraulic adjustment system, one-button adjustment of discharge particle size.

2. PEC Series Electric Portable Jaw Crusher: Zero-emission design, suitable for environmentally sensitive areas.

3. PEM Series Modular Portable Jaw Crusher: Quick assembly and disassembly design, suitable for extremely narrow sites.

Frequently Asked Questions (FAQ)

Q1: Is the production capacity of portable jaw crushers lower than that of fixed equipment?

A: Modern portable equipment has a single-machine capacity close to that of a medium-sized fixed crushing plant. Through optimized cavity design and power systems, some models can achieve a production capacity of 300-500 tons/hour, fully meeting the needs of most small and medium-sized projects.

Q2: How long does it take to relocate the equipment?

A: The new generation of equipment uses a hydraulic folding mechanism and quick-connect design. From stopping operation to transportation status usually only takes 30-60 minutes. Some models even support a crushing while moving mode.

Q3: Is equipment maintenance more complex than fixed equipment?

A: Actually, it's simpler. The modular design makes key components easier to disassemble, and the centralized lubrication system and remote diagnostic functions significantly reduce on-site maintenance workload. We provide a global spare parts network and online technical support.

Industry Outlook

By 2026, with the deep integration of 5G IoT, artificial intelligence, and new energy technologies, portable jaw crushers will no longer be simply mobile equipment, but will evolve into intelligent crushing workstations. As a manufacturer with 20 years of technological expertise, we will continue to invest in research and development to provide our customers with more efficient, environmentally friendly, and intelligent crushing solutions, and together we will embrace a new era in the mining and crushing industry.