Rock, Concrete, Asphalt, and Granite Jaw Crusher Manufacture

In industries such as mining, building demolition, road reconstruction, and aggregate production, rock, concrete, asphalt, and granite are among the most common and challenging materials to process. These materials are highly hard and abrasive, making them difficult for ordinary crushing equipment to handle, resulting in low efficiency and severe wear. Therefore, jaw crushers, specifically designed to handle these high-hardness, highly abrasive materials, have become a core requirement in the industry. Their unique working principle and robust structural design enable them to handle various demanding conditions, from primary to secondary crushing.

20 Years of Technological Expertise: Building a Solid Foundation for Crushing

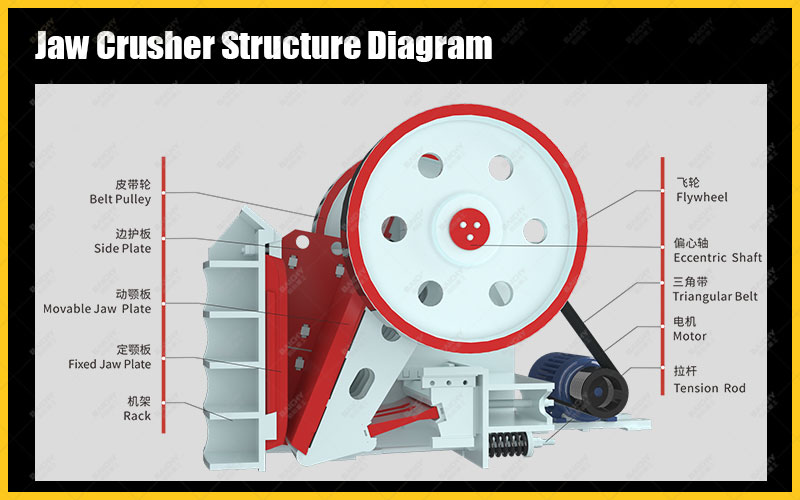

As a mining crushing equipment manufacturer with 20 years of experience, we deeply understand the challenges that different material characteristics pose to the crushing process. Our jaw crushers, optimized for crushing rock, concrete, asphalt, and granite, combine classic structure with modern innovation. The equipment utilizes the principle of the movable jaw periodically squeezing the material. Through optimized cavity design and stronger crushing force, it ensures reliable crushing and high processing capacity for hard materials, making it the ideal core equipment for various primary crushing stations.

The structure of the PE jaw crusher.

Core Advantages: Why Choose Our Jaw Crusher?

1. Exceptional Durability and High-Strength Frame: Utilizing high-quality cast steel or welded heavy-duty frames, and equipped with larger shafts and bearings than competitors, it is specifically designed to withstand the continuous high stress from crushing granite and concrete, significantly extending its lifespan.

2. High Efficiency and High Throughput: The optimized deep crushing chamber and larger feed opening design not only increase the single-pass processing capacity, but its higher crushing ratio also reduces the pressure on subsequent crushing stages, resulting in an overall efficiency increase of approximately 30%.

3. Low Operating and Maintenance Costs: Replaceable wear-resistant liners protect the core frame, making replacement convenient; the hydraulic discharge opening adjustment device is safe and easy to operate, greatly reducing downtime and lowering long-term operating costs.

4. Wide Applicability: From the hardest granite to resilient recycled concrete and asphalt pavement materials, one machine can flexibly handle various materials, helping customers expand their persified businesses.

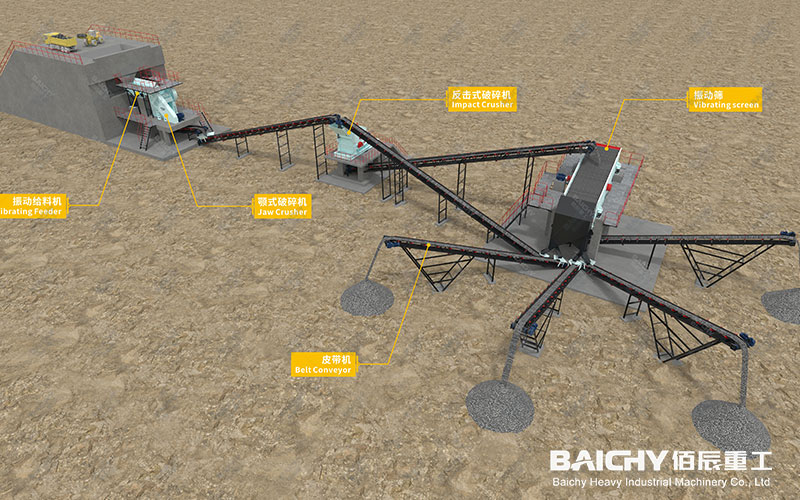

Stationary crushing production line

Application Cases: Global On-Site Verification

* North China Granite Quarry Project: The customer uses our PEV series large jaw crusher as the primary crusher to process raw granite ore, achieving a stable output of over 800 tons per hour. The equipment has been running continuously for over 2 years, with long replacement cycles for key wear parts, saving the customer significant maintenance costs.

* Southeast Asia Urban Construction Waste Recycling Center: Our medium-sized jaw crusher is used to crush discarded concrete and asphalt blocks. Its powerful impact resistance and anti-clogging design effectively handle complex materials containing rebar, producing uniform output particle size and laying a good foundation for subsequent sand production processes.

Jaw Crushing Plant

Recommended Related Equipment

To build a more efficient and complete crushing production line, we recommend linking this jaw crusher with the following equipment:

1. Medium and Fine Cone Crusher: As a secondary crusher, it further processes the semi-finished products from the jaw crusher, especially suitable for processing high-hardness granite aggregates, resulting in excellent finished product particle shape.

2. Heavy-Duty Feeder: Ensures that large rocks and concrete are fed into the jaw crusher evenly and continuously, preventing blockages and maximizing the jaw crusher's capacity.

3. Mobile Crushing Plant: Integrates this jaw crusher onto a mobile chassis, forming a flexible mobile crushing unit, particularly suitable for on-site asphalt pavement recycling and decentralized processing of construction waste.

Frequently Asked Questions (FAQ)

Q1: What is the maximum feed size that this jaw crusher can handle?

A1: This depends on the specific model. Our jaw crusher series has a maximum feed opening size of over 1500mm, easily handling large rocks and concrete blocks. Specific parameters need to be selected based on your material characteristics and production targets.

Q2: Is it prone to sticking or clogging when crushing sticky materials like asphalt?

A2: We have considered this. The equipment's cavity design is more streamlined, and optional heating devices or special liner surface treatments are available to effectively reduce the adhesion of wet and sticky materials (such as recycled materials containing asphalt), ensuring smooth production.

Q3: Compared to your competitors, what is the main difference that your 20 years of experience brings?

A3: Our 20 years of deep industry experience have allowed us to accumulate a vast database of materials and application cases. Our difference lies in deep customization: we can fine-tune equipment parameters, such as eccentric shaft speed and toggle plate angle, based on the specific hardness, silicon content, and abrasiveness of the materials you are processing (such as granite characteristics). This allows us to provide a tailor-made solution, rather than just standard machines, ensuring optimal performance and durability of the equipment under your specific working conditions.