Cone Crusher Supplier | For Ethiopia

Ethiopia is experiencing a period of rapid economic growth and extensive infrastructure development. From national-level projects like the Grand Renaissance Dam to roads, railways, and urban construction across the country, the demand for high-quality aggregate is unprecedented. Simultaneously, Ethiopia's abundant mineral resources are in urgent need of efficient development. In this context, choosing an efficient, reliable, and durable cone crusher has become crucial for the success of quarry and mine owners. As a manufacturer of mining crushing equipment with 20 years of professional experience, we deeply understand the challenges and needs of the local market and provide customized cone crusher solutions.

| Key Words | Cone Crusher Supplier |

|---|---|

| Product Model | Symons Cone Crusher |

| Feed Size | ≤284mm |

| Motor Power | 75-400kw |

| Capacity | 27-1814t/h |

| Core Advantages | Lamination failure, overload protection. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

The Hard Rock Crusher for Medium and Fine Crushing

Cone crushers, with their unique lamination crushing principle and stable structure, are designed specifically for processing medium to high-hardness ores and rocks. Combined with jaw crushers in a classic jaw crusher + cone crusher production line, they are the core equipment for producing high-quality aggregate with uniform specifications and cubic particle shape. They are particularly suitable for processing highly abrasive materials common in Ethiopia, such as granite, basalt, and river pebbles.

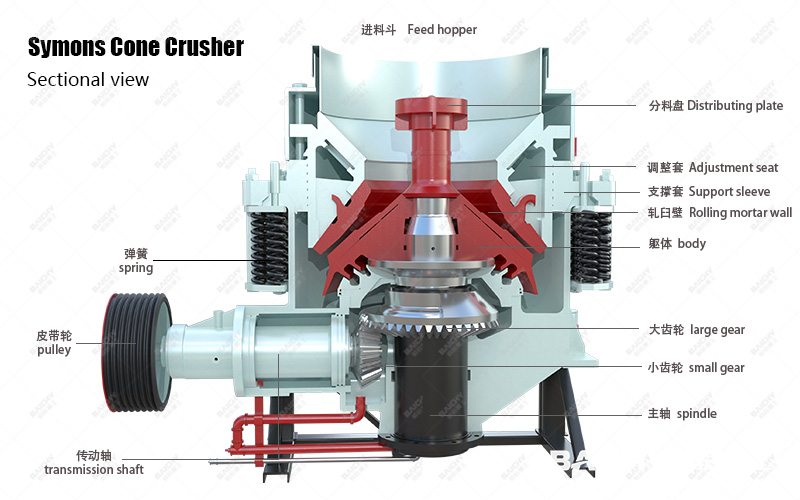

Symons Cone Crusher Structural Diagram

Core Working Principle and Types

The core principle is that the material is continuously squeezed, impacted, and bent between the stationary cone and the eccentrically rotating moving cone, achieving continuous crushing. Based on their application, they are mainly pided into:

• Spring Cone Crusher: Traditional and reliable, with strong overload protection capabilities.

• Hydraulic Cone Crusher (Single-cylinder/Multi-cylinder): Modern mainstream, highly automated, easy to adjust the discharge opening and clear the cavity, resulting in higher production efficiency.

• Compound Cone Crusher: Combines the advantages of spring and hydraulic crushers, offering outstanding cost-effectiveness.

Our Cone Crusher's Core Advantages

Designed for Ethiopia's Demanding Working Conditions

Based on 20 years of global application experience, especially our understanding of the African market, our cone crushers possess the following outstanding advantages, perfectly matching the needs of Ethiopian customers:

1. Excellent Wear Resistance and Long Service Life: The core crushing parts (mantle and concave) are made of high-manganese steel or special alloys, and undergo optimized heat treatment processes, increasing wear resistance by more than 30%, significantly reducing replacement frequency and operating costs when crushing high-hardness materials.

2. High Efficiency and Energy Saving, Low Operating Costs: The optimized crushing chamber design and higher swing speed enable higher processing capacity and finer product under the same power. The efficient hydraulic system and drive design effectively reduce unit energy consumption, saving valuable electricity costs for customers.

3. Intelligent Hydraulic Control and Easy Operation: Equipped with an advanced hydraulic system, it achieves one-button adjustment of the discharge opening and one-button chamber cleaning, significantly reducing downtime and manual intervention. The PLC control system monitors the operating status in real time, ensuring the equipment operates under optimal load.

4. Excellent Finished Product Particle Shape: The lamination crushing principle ensures excellent aggregate particle shape and low needle-like and flaky content, which is crucial for high-standard concrete pouring and asphalt pavement construction, significantly improving the quality of the final construction project.

5. Robust Structure and Global Service Network: The heavy-duty frame design ensures stable operation under continuous heavy load. We have service points and spare parts warehouses in Africa, providing timely technical support, installation guidance, and spare parts supply to Ethiopian customers, eliminating worries.

Symons cone crusher customer site

Our Cone Crushers in Similar Regional Applications

Our equipment has been widely used in many large-scale projects worldwide. For example, in a granite quarry in an East African country, the customer used one of our HPM400 multi-cylinder hydraulic cone crushers, combined with a jaw crusher for two-stage crushing. This equipment efficiently achieved a stable output of 350 tons per hour, with uniform aggregate particle shape, fully meeting local highway construction standards. The equipment ran continuously for over 6000 hours, and the core wear parts remained in good condition, receiving high praise from the customer.

Complete Crushing and Screening Solutions

A cone crusher needs to work in conjunction with other equipment. We can provide Ethiopian customers with complete production line design and equipment supply:

• Primary Crushing: PE/PEX series jaw crushers for powerful coarse crushing.

• Feeding and Screening: ZG series vibrating feeders and YK series circular vibrating screens to ensure uniform feeding and accurate classification.

• Conveying System: TD series belt conveyors to connect the entire process. • Mobile Crushing Plants: If you require a more flexible relocation solution, we also offer wheeled or tracked mobile cone crushing plants.

Frequently Asked Questions (FAQ)

1. What is the replacement cycle for the main wear parts of the cone crusher in Ethiopia?

This mainly depends on the hardness (abrasiveness) of the crushed material. For typical granite crushing, under normal working conditions and maintenance, the service life of our high-manganese steel crushing liners/mantles is usually between 800-1500 operating hours. We offer wear parts made of different materials for you to choose from, balancing initial investment and operating costs.

2. How adaptable is the equipment to the power supply?

We can fully customize the motor and electrical system according to the local voltage and frequency standards in Ethiopia (such as 380V/50Hz), ensuring that the equipment is ready to use upon arrival without requiring any additional modifications from the customer.

3. Can you provide on-site installation guidance and operation training?

Absolutely. We provide comprehensive pre-sales, in-sales, and after-sales services. This includes free basic engineering design support, dispatching engineers for on-site installation and commissioning guidance, and providing systematic training for your operation and maintenance team to ensure the production line is successfully put into operation and achieves optimal performance.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.