Belt Conveyor

In modern mining and aggregate production, mobile crushing and screening plants have become the industry standard due to their flexibility and efficiency. However, within this highly integrated mobile plant, there is a core component that, while not directly involved in "crushing" and "screening," acts as the "artery" connecting the entire production process and ensuring its continuous and efficient operation – the belt conveyor.

Overview: More than just "transportation"

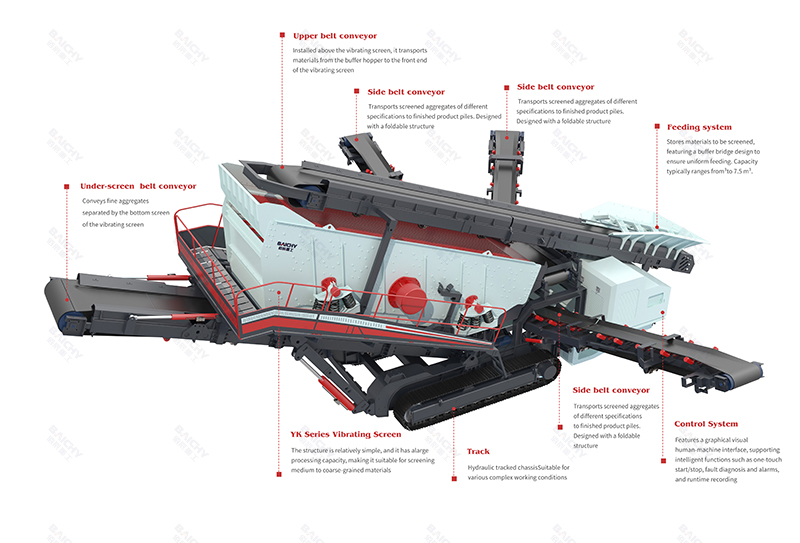

Belt conveyors play a crucial role in material handling within mobile crushing and screening plants. They are responsible for transporting raw materials from the feeder to the jaw crusher, transferring the primary crushed material to the cone crusher or impact crusher, and then accurately delivering aggregates of different particle sizes before and after screening to designated locations (such as finished product stockpiles or return material cycles). A well-designed conveyor system ensures smooth and unobstructed material flow through each process, maximizing the efficiency and capacity of the entire production line.

Key Role of Belt Conveyors in the Process

Connecting process stages: Seamlessly connecting various modules such as feeding, crushing, screening, and stockpiling, forming a continuous operation.

Regulating production pace: By controlling the conveying speed and start/stop, it coordinates the production rhythm of upstream and downstream equipment, avoiding equipment idling or overloading.

Reducing overall costs: Compared to traditional vehicle transportation, belt conveyors significantly reduce fuel consumption and labor costs, making them the most economical material handling solution for long-term operation.

Core Advantages: Why it's an essential choice for mobile plants

Equipping mobile crushing and screening equipment with an optimized belt conveyor system brings immediate benefits.

Improved overall operational efficiency

Dedicated mobile belt conveyors are designed to work in conjunction with the main equipment, enabling quick positioning and connection. Smooth material flow eliminates waiting times, allowing the crushing host to operate continuously at near-maximum theoretical capacity, significantly increasing the daily processing volume of the entire work area.

Enhanced system flexibility and scalability

The modular design of the belt conveyor system allows for various layouts of the mobile plant based on site topography and process requirements. Whether it's a straight line arrangement, an L-shaped layout, or multi-stage climbing, flexible conveying solutions can easily handle diverse situations. When future process adjustments are needed, you only need to add, remove, or rearrange the conveyor units, offering excellent scalability.

Reduced Operating Costs and Maintenance Difficulty

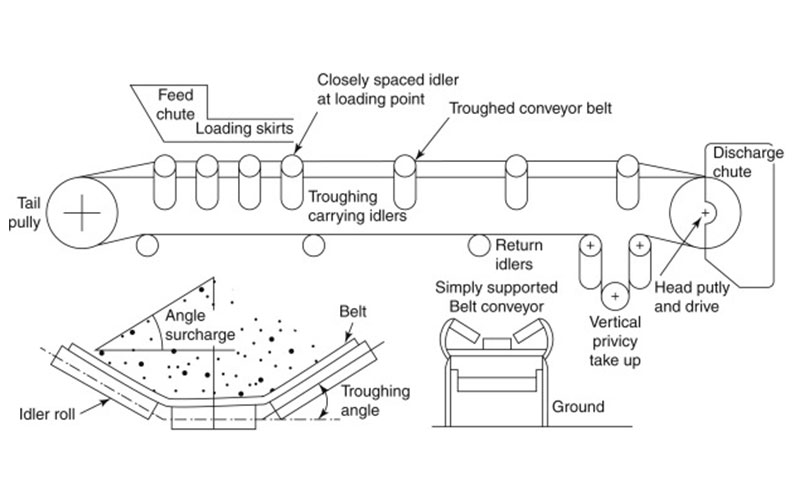

Belt conveyors consume significantly less energy than loaders and trucks. Their relatively simple structure and easy maintenance of core components (such as rollers, idlers, and belts) result in fewer failure points, effectively reducing unplanned downtime and lowering long-term operating and maintenance costs.

| Belt width (mm) |

Conveying length (m)

Power (kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

| 500 |

≤ 12/3 |

≤ 12-20/4-5.5 |

≤ 20-30/5.5-7.5 |

1.3-1.6 |

40-100 |

| 650 |

≤ 12/4 |

≤ 12-20/5.5 |

≤ 20-30/7.5-11 |

1.3-1.6 |

80-120 |

| 800 |

≤ 10/4 |

≤ 10-15/5.5 |

≤ 15-30/7.5-15 |

1.3-1.6 |

120-200 |

| 1000 |

≤ 10/5.5 |

≤ 10-20/7.5-11 |

≤ 20-40/11-22 |

1.3-2.0 |

200-320 |

| 1200 |

≤ 10/7.5 |

≤ 10-20/11 |

≤ 20-40/15-30 |

1.3-2.0 |

300-500 |

Application Case: Excellent Performance in Real-World Conditions

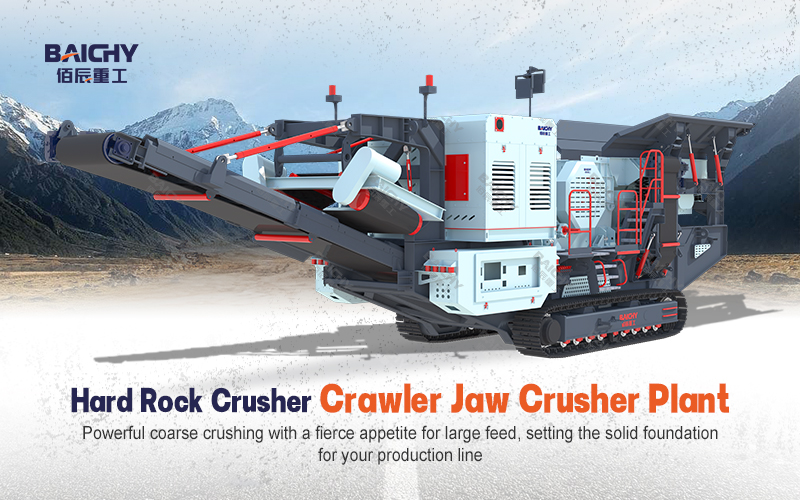

Our experience in a large granite quarry project in Southeast Asia fully demonstrates the importance of a high-quality conveying system. The client adopted our "crawler-mounted jaw crusher + crawler-mounted cone crusher + mobile screening plant" combination. We designed multiple heavy-duty, tear-resistant belt conveyors for them, including a main discharge belt conveyor over 20 meters long with a climbing angle of 18 degrees.

In continuous, high-intensity production operations, this conveying system performed exceptionally well: anti-deviation and anti-spillage designs ensured a clean site environment; high-impact idlers withstood the impact of large-sized material falling from the cone crusher; the entire system ran smoothly, helping the quarry achieve a stable output of 450 tons per hour and completing production targets ahead of schedule due to efficient continuous operation.

Equipment Selection Recommendations

Choosing the right belt conveyor requires considering multiple factors. As a manufacturer, we recommend that you focus on the following points:

Matching the main equipment's capacity: The belt conveyor's width, speed, and maximum inclination must meet the maximum discharge capacity and material characteristics of the crushing equipment.

Focus on the quality of key components:

Belt: Choose a wear-resistant, tear-resistant grade, especially at the loading point.

Drive and tensioning: A powerful and reliable drive motor and automatic tensioning device are essential for stable operation.

Structural strength: The rigidity and fatigue resistance of the frame determine its reliability during mobile transfers and long-term use.

Intelligent control integration: Choose a conveyor that can be integrated with the main equipment's control system to achieve one-button start/stop, interlocking control, and fault alarms, moving towards intelligent management.

Frequently Asked Questions (FAQ)

Q1: Can the belt conveyor on the mobile station be adjusted at multiple angles?

Yes. Most modern mobile crushing and screening equipment features discharge conveyor belts with hydraulic or mechanical lifting and slewing capabilities. Hydraulic adjustment is more common, allowing the operator to easily control the discharge height and lateral swing angle (typically up to ±30° or more) of the conveyor belt from the cab, adapting to different heights of transport vehicles or stacking locations, greatly increasing operational flexibility.

Q2: How to address belt misalignment and material spillage issues?

This is a key indicator of conveyor design quality. High-quality designs include multiple anti-misalignment measures, such as self-aligning idler sets and V-shaped forward-tilting side rollers. At the receiving point, buffer rollers, sealed guide chutes, and wear-resistant skirt boards are designed to prevent impact and spillage. Regularly checking the flexibility of the idler rollers and adjusting the tension are also important maintenance tasks to prevent misalignment.

Q3: Do belt conveyors require special configurations in extremely cold or rainy environments?

Yes. For extremely cold regions, low-temperature resistant belt materials and bearing lubricants should be used to prevent embrittlement and freezing. For rainy or humid environments, rain covers can be considered, and the motor and drive components need to meet a higher protection rating (such as IP65). In working conditions prone to sticky mud, the belt surface can use special patterns or coatings to reduce adhesion.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!