Tanzania Dolomite Grinding Mill Production Line Supplier

Recently, we received an inquiry from a client in Tanzania, whose core requirement focused on a dolomite grinding production line. This is not just an ordinary inquiry, but a reflection of the African continent's industrialization process and its demand for efficient and reliable mining equipment. As a manufacturer of mining crushing and grinding equipment with 20 years of extensive technical experience, we understand that every production line exported overseas carries the development dreams of our clients. This article will delve into the applications and prospects of dolomite processing and demonstrate why we are your trustworthy partner.

Tanzania possesses abundant dolomite mineral resources. This mineral is a key raw material for the preparation of magnesium salts, and the production of refractory materials, glass, ceramics, and soil conditioners. With the booming development of Tanzania's construction and agricultural industries and the urgent need for industrialization, localized and large-scale dolomite deep processing has become an inevitable trend. An efficient dolomite grinding production line can transform raw ore into high-value-added powders of different fineness (80-2500 mesh), directly meeting or creating local market demand, reducing import dependence, and creating jobs and economic benefits.

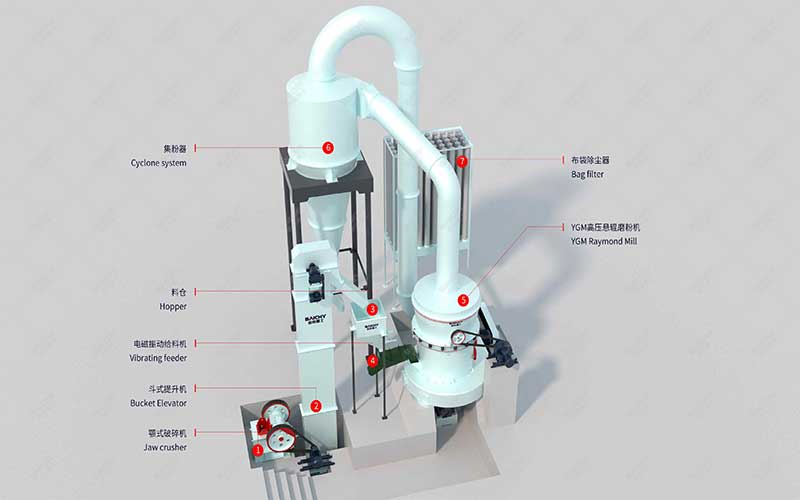

Dolomite grinding production line

Production Line Core Overview

A complete dolomite grinding production line is not simply a combination of a few machines, but a systematic engineering project. It typically includes the following core stages:

1. Coarse Crushing and Conveying Stage

Large pieces of raw ore are uniformly fed into a jaw crusher by a vibrating feeder for preliminary crushing. The crushed material is then transported to the next stage by a belt conveyor.

2. Medium and Fine Crushing and Grinding Stage

This is the core of dolomite grinding. After medium and fine crushing by a hammer crusher or cone crusher, materials of the appropriate particle size are sent to a Raymond mill, high-pressure suspension roller mill, or a more advanced vertical grinding mill for fine grinding. We can customize the most suitable grinding mill model for you based on your target powder fineness and output.

3. Classification and Collection Stage

The ground powder is carried by airflow into a classifier. Materials that do not meet the fineness requirements are returned for regrinding, while the qualified fine powder enters a pulse dust collector for collection, resulting in the finished product. The entire process is conducted under negative pressure, ensuring an environmentally friendly and dust-free operation.

Our Core Advantages: Reliable Quality Forged by 20 Years of Experience

Choosing us means you'll receive a "turnkey" project, not just equipment procurement.

• Mature Process Solutions: For 20 years, we have provided hundreds of grinding production lines to over 50 countries worldwide, possessing a rich project database and process expertise in the processing of non-metallic minerals such as dolomite, calcite, and barite.

• High Equipment Adaptability and Durability: We understand the challenges of local power stability and maintenance convenience in Tanzania. Our equipment design balances efficiency and strong adaptability, with key components made of high-strength materials to ensure long-term stable operation in harsh environments.

• Comprehensive Technical Services: From on-site surveys, process design, equipment installation and commissioning to operator training, we provide one-stop service. Our multilingual (English, Swahili technical manual support) technical support team ensures seamless communication.

Tanzania flour milling production line site

Success Story

We provided a 15-ton per hour dolomite grinding production line to a building materials company in Ethiopia, used for producing paint fillers and putty powder raw materials. The project took only 4 months from contract signing to commissioning, with the finished product fineness consistently at 200 mesh, fully meeting customer requirements. The equipment has been operating stably for 3 years, and its excellent powder output rate and low failure rate have earned high praise from the customer, who subsequently chose our equipment again for their expansion.

Related Equipment Recommendations

In addition to the core grinding mill, an efficient production line also requires the following high-quality equipment:

• PE Series Deep Cavity Jaw Crusher: Used for coarse crushing of dolomite, with a large crushing ratio and robust structure.

• HC Series Pendulum Grinding Mill: Suitable for 80-400 mesh fineness processing, with low energy consumption and high cost-effectiveness.

• Pulse Bag Dust Collector: Ensures that the entire dolomite grinding production line meets strict environmental standards and achieves green production.

Frequently Asked Questions (FAQ)

1. What are the power consumption and installation site requirements for the entire production line in Tanzania?

Power consumption depends on the production line capacity and finished product fineness. Taking a production capacity of 10 tons per hour (200 mesh) as an example, the total power consumption is approximately 300-400 KW. We will calculate the exact requirements based on your specific needs. The site needs sufficient space to accommodate the equipment (approximately 40-60 meters long and 20-30 meters wide) and raw material/finished product storage areas, and must meet the basic load-bearing and power supply requirements.

2. What are the replacement cycle and cost of the equipment's wear parts?

Grinding rollers, grinding rings, and scraper blades are the main wear parts. Their service life depends on the hardness and abrasiveness of the material and maintenance conditions. Under normal processing of dolomite, the core grinding roller can last for 800-1500 hours. We provide original spare parts at transparent prices and guide you on scientific maintenance to extend their lifespan.

3. Can you provide localized after-sales and maintenance support?

Yes, this is one of our major advantages. We have resident service engineers and spare parts warehouses in East Africa, enabling us to provide rapid on-site response. At the same time, we provide each customer with detailed video operation guides and regular remote diagnostic services to ensure the continuous and efficient operation of the production line.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!