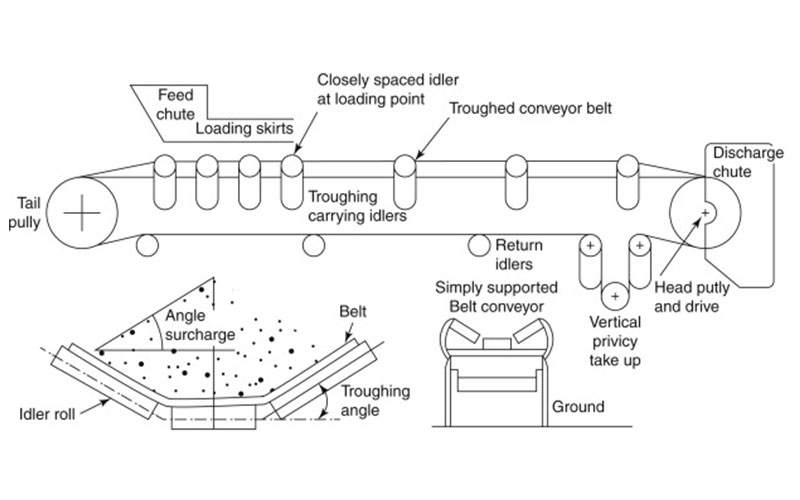

Belt Conveyor

In mobile crushing production lines, the conveyor belt plays a silent yet crucial role. It's not only the link connecting the feeding, crushing, and screening units, but also the frontline component directly subjected to the most severe challenges – the impact of sharp materials, continuous wear, and critical challenges from hot materials. As a manufacturer of mobile crushing equipment for the mining industry, we understand that a durable and heat-resistant conveyor belt is fundamental to ensuring the continuous, efficient, and safe operation of the entire production line. This article will delve into why this type of specialized conveyor belt is a wise investment.

Core Challenges: Why are Specialized Conveyor Belts Necessary?

Primary aggregates from jaw crushers have sharp edges and high impact force; while materials from impact crushers or cone crushers may carry high temperatures, especially when processing silica, basalt, or recycled asphalt pavement (RAP). General-purpose conveyor belts quickly encounter the following problems in this environment:

Cover layer cuts and peeling: Sharp stones penetrate or cut the belt body.

Carcass layer damage: Strong impacts cause canvas or steel cord core breakage.

Thermal aging and cracking: High temperatures cause the rubber to harden, lose elasticity, and eventually crack.

Abnormal wear: Rapid wear significantly reduces service life, and frequent replacement increases downtime and costs.

Therefore, Crusher Conveyor Belts specifically designed for crushing applications must combine exceptional durability and excellent heat resistance.

| Belt width (mm) |

Conveying length (m)

Power (kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

| 500 |

≤ 12/3 |

≤ 12-20/4-5.5 |

≤ 20-30/5.5-7.5 |

1.3-1.6 |

40-100 |

| 650 |

≤ 12/4 |

≤ 12-20/5.5 |

≤ 20-30/7.5-11 |

1.3-1.6 |

80-120 |

| 800 |

≤ 10/4 |

≤ 10-15/5.5 |

≤ 15-30/7.5-15 |

1.3-1.6 |

120-200 |

| 1000 |

≤ 10/5.5 |

≤ 10-20/7.5-11 |

≤ 20-40/11-22 |

1.3-2.0 |

200-320 |

| 1200 |

≤ 10/7.5 |

≤ 10-20/11 |

≤ 20-40/15-30 |

1.3-2.0 |

300-500 |

Exclusive Advantages: How Durability and Heat Resistance are Achieved

A qualified conveyor belt for crushing applications addresses these challenges through material and structural innovation. Its main advantages are reflected in:

Exceptional Impact and Tear Resistance

Using high-tension, high-elasticity carcass materials (such as heavy-duty EP canvas or steel cord core), combined with a specially designed thick, highly wear-resistant rubber cover layer. This structure effectively absorbs the impact of large materials falling, resists penetration and longitudinal tearing by sharp materials, and significantly improves the durability of the belt in the critical area of the crusher discharge port. H3: Excellent High-Temperature Resistance

Heat-resistant conveyor belts are not completely impervious to high temperatures, but rather can withstand a specific temperature range without rapid aging. Their cover rubber uses a special EPDM or SBR blend formula, maintaining physical properties at material temperatures up to 150°C-180°C (for short periods), preventing premature hardening, cracking, and delamination of the rubber, ensuring reliability when conveying hot asphalt or high-temperature crushed stone.

Optimized Total Cost of Ownership (TCO)

Although the initial investment may be higher than for ordinary conveyor belts, their exceptionally long service life, extremely low failure rate, and reduced replacement frequency directly reduce downtime, maintenance costs, and parts inventory. In the long run, choosing durable and heat-resistant conveyor belts effectively lowers the total cost of ownership and ensures production efficiency.

Case Study: How Heat-Resistant Conveyor Belts Solved a Customer's Problem

One of our customers encountered difficulties when processing recycled asphalt (RAP). The high temperature of the recycled asphalt processed by their mobile impact crusher caused the original conveyor belt to harden, crack extensively, and wear at the edges within three months. Frequent downtime for repairs severely impacted project progress.

Solution: We recommended and replaced it with a specially designed HR (Heat Resistant) heavy-duty conveyor belt, which features a thicker heat-resistant cover layer and reinforced edge protection.

Results: After replacement, the conveyor belt operated stably for over 12 months under the same working conditions, showing only normal wear and tear, without any signs of heat aging or cracking. The customer's production continuity was ensured, and overall operating costs were significantly reduced.

How to Choose and Maintain? Our Professional Recommendations

Choosing the right crusher conveyor belt requires considering:

Material type: Hardness, sharpness, and particle size.

Material temperature: Normal temperature and peak temperature.

Crusher type: Equipment with higher impact force (such as impact crushers) requires a higher impact resistance rating.

System parameters: Belt width, belt speed, and tension.

We recommend regularly inspecting the belt, paying attention to cover wear, edge damage, longitudinal scratches, and the condition of the splices. Ensure the conveyor belt cleaner is functioning correctly to prevent sharp materials from getting caught in the return section and causing damage. Establish a preventative replacement plan instead of waiting for complete failure.

Frequently Asked Questions (FAQ) about Crusher Conveyor Belts

FAQ 1: Are all crusher conveyor belts heat-resistant?

No. Heat resistance (HR) is a specific rating. Standard wear-resistant conveyor belts are primarily designed for materials at ambient temperature. If you are handling hot materials (such as RAP, freshly produced clinker, or certain high-temperature ores), you must specify this and select Crusher Conveyor Belts with an HR rating, whose cover rubber compound and structure are specifically designed for heat aging resistance.

FAQ 2: How can I tell if my conveyor belt needs to be upgraded to a more durable/heat-resistant model?

Observe the following: abnormally rapid wear or cuts on the cover layer; numerous small cracks on the belt surface (thermal aging); frequent visible damage to the carcass layer; or an increase in unplanned downtime due to belt problems. If any of these occur, you should evaluate upgrading to a higher-performance, specialized conveyor belt.

FAQ 3: Can heat-resistant conveyor belts be used in any high-temperature application?

There are temperature limits. Common HR-type conveyor belts are typically designed for material temperatures of ≤150°C to 180°C. If the material temperature consistently exceeds 200°C, a more specialized model (such as an extremely high heat-resistant type) is required. Always provide your supplier with accurate material temperature information.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!