Spiral Conveyor Chutes | Gravity Chutes

High-Efficiency Conveying and Sorting Tools in Mineral Processing

In complex mineral processing workflows, efficient and low-cost material conveying and pre-sorting are crucial for overall efficiency. As a mineral processing equipment manufacturer with 20 years of experience, we understand the importance of having the right tools for the job. Spiral chutes and gravity chutes, two types of equipment with similar names but different functional focuses, are classic solutions for achieving this goal. They both utilize the material's own gravity as the primary power source, but due to their unique designs, they each have their own advantages in application scenarios, sorting accuracy, and space utilization. This article will provide an in-depth analysis of these two types of equipment to help you make the most informed choice.

| Key Words | Spiral Conveyor Chutes | Gravity Chutes |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Functionally Different Twin Brothers

Gravity Chute: The Sorting Master Focused on Material Classification

Gravity chutes, usually referring to inclined chutes or vibrating chutes, primarily utilize the differences in speed and trajectory of material particles moving on an inclined surface due to differences in density, particle size, and shape for sorting. It is not simply a conveying pipe, but a sorting device. Material is fed from the top, and as it slides or rolls down the chute, heavier mineral particles stay closer to the bottom of the chute, while lighter mineral particles remain in the upper layer, thus achieving separation. Its structure is relatively simple, with no moving parts (except for vibrating types), and the sorting effect is mainly adjusted by the slope angle.

Spiral Conveying Chute: A Space-Saving Conveying and Sorting All-Rounder

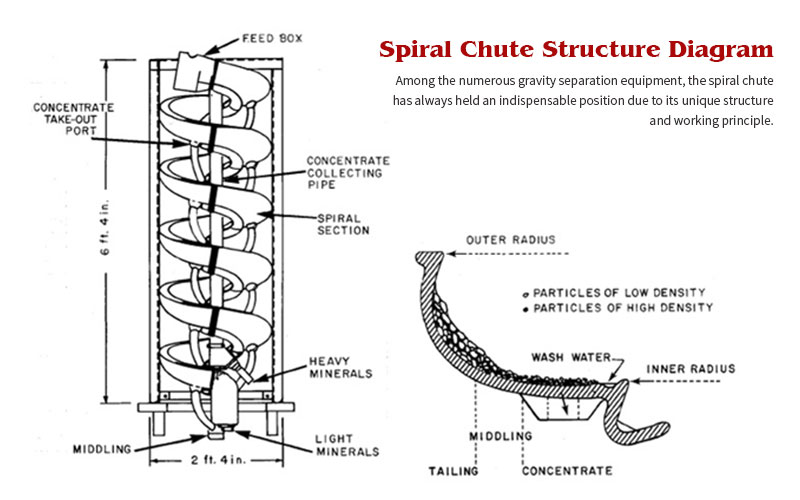

The core of the spiral conveying chute lies in its spiral structure. It arranges a continuous spiral-shaped chute vertically around a central column. After the material is fed from the top, it rotates downwards along the spiral chute under the combined action of gravity and centrifugal force. This process cleverly combines vertical conveying and light sorting functions. It achieves high-altitude material conveying within a very small footprint, and at the same time, during the conveying process, denser particles tend to accumulate towards the outer edge of the chute, allowing for preliminary enrichment or de-sliming.

Spiral chute structure diagram

Core Advantages Comparison: How to Tailor the Solution for Your Mine?

Advantages of Gravity Chutes

• High-efficiency separation: High separation efficiency for minerals with coarser particle sizes or significant density differences (such as gold, tin, and tungsten ores).

• Simple structure and low maintenance costs: No complex transmission mechanisms, fewer failure points, and reliable operation.

• Large processing capacity: Flexible design of chute width and length can meet the separation needs of high-flow materials.

• Extremely low energy consumption: Driven entirely by gravitational potential energy, resulting in significant energy savings.

Advantages of Spiral Conveyor Chutes

• Extreme space saving: Vertical arrangement, using height to save area, especially suitable for factories with limited space or processing plants requiring multi-story layouts.

• Two-in-one conveying and separation: While completing vertical lifting or lowering, it also provides a separation effect, simplifying the process.

• Good sealing and environmental protection: Can be designed as a fully enclosed structure, effectively preventing dust dispersion and meeting environmental requirements.

• Smooth operation and low noise: Material friction with the chute is the main interaction, without strong impact, resulting in a friendly working environment.

Application Case Studies: 20 Years of Experience, Witnessing Success

1. Case Study 1: Pre-selection stage of a certain iron mine

• Challenge: The raw ore contains a large amount of low-grade waste rock, and direct grinding results in excessively high energy consumption.

• Solution: Using our designed large-angle gravity chute, pre-discarding of -30mm material is performed after crushing and before grinding. Heavy minerals (iron ore) are enriched at the bottom of the chute and enter the next process, while light gangue is discharged from the top.

• Results: The grade of the material entering the grinding process increased by 15%, and the grinding energy consumption decreased by approximately 20%, resulting in significant economic benefits.

2. Case Study 2: Re-selection project of a certain tailings pond

• Challenge: The tailings pond still contains recoverable fine-grained valuable minerals, but the available flat ground space is extremely limited.

• Solution: Deploying multiple sets of large spiral conveyor chutes, the low-concentration tailings slurry is transported from the ground to the top feed distributor. During the spiral descent, fine-grained heavy minerals are enriched and recovered. • Results: Achieved secondary utilization of tailings resources with minimal use of new land, resulting in an annual recovery value exceeding one million RMB.

Equipment Selection and Recommendations

The choice of equipment depends on your core needs:

• If your primary goal is efficient separation, especially for coarse-grained materials, gravity chutes are your best choice. We offer various models with different chute surface materials (such as PU, fiberglass, and rubber lining) and widths (200mm-1500mm).

• If your pain point is limited space or you need vertical conveying combined with separation, a spiral conveying chute is a better solution. We offer single-head, double-head, and multi-layer spiral designs with diameters ranging from 500mm to 2000mm to meet different processing capacities and site requirements.

We recommend combining the two, for example, using a spiral conveying chute to lift the raw ore to a higher level, and then using a gravity chute group for fine classification, creating an efficient and compact process flow.

Frequently Asked Questions (FAQ)

Q1: Is the slope of the spiral conveying chute fixed? How is the separation effect adjusted?

A: Yes, the pitch and spiral angle of the spiral chute are determined during manufacturing. Adjustment is mainly achieved by controlling the feed rate, feed concentration, and setting interceptors at specific positions at the bottom of the chute to collect products of different densities, thereby optimizing the effect.

Q2: Can the slope of the gravity chute be adjusted?

A: Yes, this is one of its key adjustment parameters. Many of our adjustable gravity chutes are equipped with hydraulic or mechanical lifting devices, allowing for stepless adjustment of the inclination angle within a certain range (usually 7°-25°) to adapt to changes in different ore properties and maintain the best separation state.

Q3: What particle sizes are suitable for each type of equipment?

A: Gravity chutes are suitable for relatively coarse materials, with an optimal particle size range usually between 0.5mm and 50mm. Spiral conveying chutes are more suitable for fine-grained and powdery materials, effectively handling particle sizes generally between 0.03mm and 2mm, and also have a certain dewatering and enrichment effect on extremely fine slurries. Spiral chutes and gravity chutes, as classic representatives of gravity separation, still play an indispensable role in modern mineral processing plants due to their low energy consumption, high efficiency, and ease of maintenance. As a manufacturer with 20 years of design and manufacturing experience, we not only provide high-quality standard equipment but also offer customized overall solutions based on your ore characteristics, site conditions, and process objectives, ensuring that every investment yields maximum value.

Further reading:

How To Reduce The Energy Consumption Of Ball Mill? 5 Practical Energy-Saving Tips

Iron Ore Beneficiation Process: Magnetic Separation/Flotation/Gravity Separation