Spiral Chute Conveyors

As a manufacturer of mineral processing equipment with 20 years of professional experience, we understand that the separation stage is crucial to the grade and recovery rate of the final product in the mineral processing process. Among numerous gravity separation equipment, the spiral chute conveyor has always held a prominent position due to its simple structure, stable operation, and energy efficiency. This article will delve into this classic equipment, providing you with a comprehensive understanding of its working principle, unique advantages, and application scenarios.

| Key Words | Spiral Chute Conveyors |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Overview of Spiral Chute Conveyor

A spiral chute, commonly referred to as a spiral concentrator, is a device that utilizes the combined effects of gravity, centrifugal force, hydrodynamic force, and friction force generated by mineral particles moving in a spiral inclined water flow to achieve separation based on density and particle size. It requires no power drive, relying solely on the gravitational potential energy and flow rate of the mineral slurry to complete the separation operation, making it a highly economical gravity separation equipment.

Detailed Explanation of Working Principle

After the mineral slurry is fed from the top of the spiral chute, it moves downwards along the spiral channel in a rotating motion. During this process, mineral particles of different properties are affected by multiple forces:

• Gravity and hydrodynamic force: These forces propel the mineral slurry to flow downwards along the chute.

• Centrifugal force: Generated due to circular motion, this force throws the particles towards the outer edge of the chute.

• Friction force: Friction between the particles and the bottom of the chute, as well as internal friction between the particles.

High-density mineral particles (such as ilmenite, wolframite, cassiterite, etc.) have larger mass and inertia, and are therefore distributed more in the inner circle of the chute, and are ultimately collected through the openings or interceptors in the inner circle.

Low-density gangue particles are more affected by hydrodynamic force and are pushed towards the outer edge, discharged from the end of the chute, thus achieving effective separation.

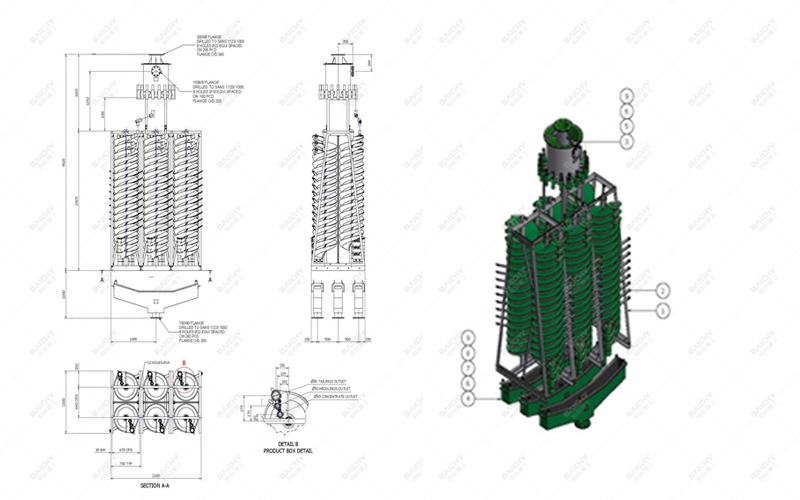

Spiral chute structure diagram

Core Advantages of Spiral Chute Conveyors

After 20 years of technological iteration and field application verification, modern spiral chute conveyors demonstrate the following unparalleled advantages:

Extremely Low Operating Costs

The equipment itself has no moving parts and requires no power drive, relying solely on the self-flow of the mineral slurry, which greatly reduces energy consumption and maintenance costs, resulting in significant long-term economic benefits. Simple Structure, Easy Maintenance

The overall structure is compact and mainly composed of a support frame, feed chute, spiral trough, product collector, and discharge chute. The modular design makes installation, commissioning, and maintenance very simple, requiring minimal technical expertise from operators.

High Processing Capacity and Stable Separation Efficiency

The processing capacity of a single unit is considerable, and it has strong adaptability to variations in feed concentration and particle size. Under suitable feed conditions, it can achieve stable and ideal separation results, especially suitable for pre-concentration and roughing of medium and fine-grained minerals.

Environmentally Friendly and Energy-Saving

The entire process relies on gravity and water flow, without the addition of chemical reagents (except for specific process flows), and there are no exhaust emissions. It is an environmentally friendly physical separation method.

Classic Application Case Study

Among our many clients, one typical case fully demonstrates the value of the spiral chute:

A coastal sand mine ilmenite beneficiation plant. The raw ore contained various valuable minerals such as ilmenite, zircon, and rutile, and the particle size was relatively fine. We designed a roughing-concentration process for them, centered around a spiral chute conveyor.

• Process: After hydraulic mining and screening, the raw ore is directly pumped to a set of (multi-layer) spiral chutes for roughing, quickly discarding a large amount of low-density tailings to obtain a rough concentrate. The rough concentrate then enters more precise spiral chutes or shaking tables for further concentration and purification.

• Results: This process successfully increased the ilmenite recovery rate by more than 15%. Because the spiral chute pre-discarded tailings, it greatly reduced the load on subsequent concentration processes, significantly reducing overall power consumption and equipment investment, bringing significant economic benefits to the client.

Equipment Selection and Recommendations

Choosing the right spiral chute is key to success. We recommend that you pay attention to the following points:

• Spiral Diameter and Pitch: Select based on processing capacity and mineral particle size; larger diameters result in higher processing capacity.

• Trough Cross-Sectional Shape: An elliptical cross-section is more suitable for fine-grained materials, resulting in a more stable flow film.

• Material: Usually made of wear-resistant fiberglass or lined with polyurethane to ensure long service life in harsh slurry environments. • **Supporting Equipment:** To maximize the efficiency of the spiral chute, we often recommend using it in conjunction with our high-efficiency hydrocyclones (for pre-classification and concentration control) and bucket elevators (for intermediate ore transportation), forming an efficient and continuous pre-treatment or separation circuit.

Frequently Asked Questions (FAQ)

FAQ 1: What particle size of minerals is best suited for spiral chutes?

Spiral chutes are most effective for separating fine-grained minerals with a particle size of 0.1-2mm. For very fine (-0.074mm) mineral fines, the separation efficiency will decrease, and it may be necessary to consider using it in combination with equipment such as centrifugal concentrators.

FAQ 2: Are there any special requirements for equipment installation?

The key to installation is ensuring overall verticality and horizontality. A plumb line must be used to ensure the verticality of the central axis, and a spirit level should be used to adjust the lateral level of each spiral chute. This is fundamental to obtaining symmetrical separation zones and ideal performance.

FAQ 3: How to adjust the spiral chute to obtain the best separation results?

The main adjustable parameters include:

1. Feed concentration: Usually controlled at 25%-40% solid weight concentration; the optimal value needs to be determined through testing.

2. Feed rate: Maintaining a uniform and stable feed is a prerequisite for stable operation.

3. Cutter position: Fine-tuning the position and opening size of the concentrate, middlings, and tailings cutting plates directly affects product quality and recovery rate.