Gold ore Ball Mill Improves Mineral Processing Efficiency

As a manufacturer with 20 years of experience in mineral processing equipment, we deeply understand that efficiency is the lifeline and recovery rate is the profit driver in gold ore beneficiation. Among many key pieces of equipment, the gold ore ball mill plays an irreplaceable "midfield engine" role, its performance directly determining the particle size, uniformity, and final indicators of subsequent beneficiation operations. This article will delve into how a high-efficiency gold ore ball mill can be the key to improving your overall mineral processing efficiency.

| Key Words | Gold Ore Ball Mill Improves Mineral Processing Efficiency |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. In-depth Analysis: Why is the Ball Mill Key to Efficiency Improvement?

In the crushing and grinding stages of gold ore beneficiation (whether it's lode gold or placer gold), the core objective is to crush the ore to a particle size that allows for complete liberation of gold minerals, facilitating effective recovery through subsequent cyanidation, flotation, or gravity separation processes.

• Efficiency Bottleneck: If the grinding particle size is insufficient or too coarse, the gold minerals cannot be completely liberated, directly leading to the loss of recoverable gold; excessive grinding not only wastes energy but may also produce slime, interfering with subsequent beneficiation. Therefore, the grinding precision and efficiency of a gold ore ball mill are crucial for controlling overall cost and benefit.

• Comparison between Traditional and Modern: Traditional ball mills may face problems such as rapid liner wear, high energy consumption, and unstable output particle size. Modern, optimized gold ore ball mills, through structural, material, and process innovations, precisely address these pain points.

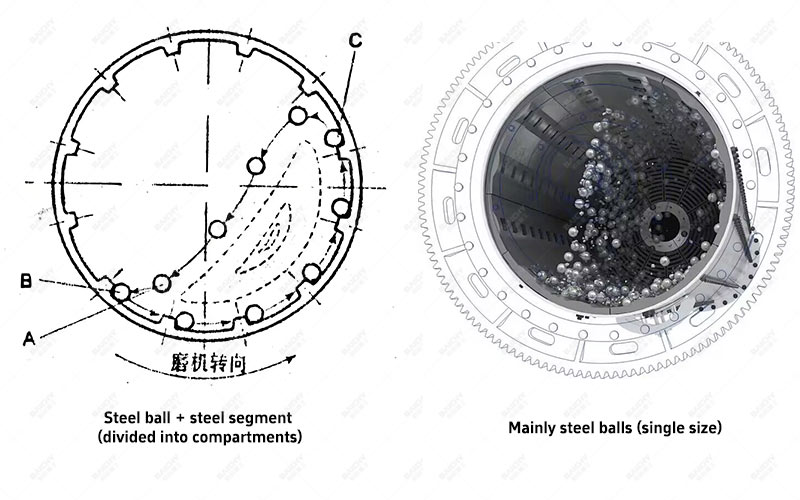

Comparison-of-grinding-media-between-tube-mill-and-ball-mill

II. Overview of High-Efficiency Gold Ore Ball Mills: Evolution of Structure and Process

A modern, high-efficiency gold ore ball mill is more than just a simple rotating cylinder. It integrates precision mechanical design, wear-resistant materials science, and intelligent control technology.

• Core Structural Optimization:

◦ Cylinder and Liners: Utilizing high-strength steel and corrugated, stepped, or other impact-resistant, high-wear-resistant alloy liners, not only protects the cylinder but also increases the height the steel balls are lifted, optimizing the grinding effect.

◦ Feeding and Discharge Devices: Improved feeders ensure uniform and continuous ore input, while advanced grate or overflow discharge designs effectively control slurry concentration and fineness, preventing over-grinding.

• Drive and Transmission System: Large rolling bearings replace traditional sliding bearings, resulting in less friction, lower energy consumption, and smoother start-up. Combined with a high-efficiency reducer and motor, reliable power transmission is achieved.

III. Significant Advantages of Investing in High-Efficiency Gold Ore Ball Mills

1. Increased Processing Capacity and Recovery Rate: Precise particle size control ensures higher liberation of gold mineral monomers, directly increasing cyanide leaching or flotation recovery rates, extracting more gold from the ore.

2. Reduced Overall Energy Consumption: Optimized design reduces ineffective friction and no-load losses, resulting in higher transmission efficiency and significantly reduced power consumption per unit of ore processed, leading to a clear long-term operating cost advantage.

3. Enhanced Operational Stability and Lifespan: The use of high-quality wear-resistant components significantly extends the replacement cycle of vulnerable parts, reduces unplanned downtime, ensures continuous and stable operation of the production line, and improves equipment utilization.

4. Reduced Maintenance Costs and Operational Difficulty: Modular design simplifies maintenance, and the intelligent control system enables remote monitoring and automatic adjustment, reducing over-reliance on operator experience.

IV. Real-world Application Case: Proven Efficiency Improvement

In a medium-sized gold mine project in West Africa that we serviced, the client previously used an old-style ball mill with a grinding fineness of only 65% (-200 mesh content) and high energy consumption. After replacing it with our high-efficiency, energy-saving gold ore ball mill:

• Under the same feed conditions, the grinding fineness consistently increased to ≥85% (-200 mesh content).

• Subsequent cyanide leaching rate increased by approximately 5 percentage points.

• Unit energy consumption decreased by approximately 18%.

• The client recovered the equipment investment cost in less than two years through increased recovery rate and energy savings.

V. Recommended Equipment

To maximize the efficiency of your gold ore ball mill, we recommend considering the following "golden combination" of equipment:

• Pre-crushing equipment: High-efficiency jaw crusher and cone crusher, achieving "more crushing, less grinding," reducing the feed particle size and fundamentally lessening the load on the ball mill.

• Classification equipment: Hydrocyclone assembly, forming a closed-loop circulation with the ball mill, promptly separating qualified products, avoiding over-grinding, and improving overall system efficiency.

• Post-processing equipment: High-efficiency centrifuges, leaching adsorption tanks, etc., perfectly integrated with high-quality ground ore products, forming an efficient and complete gold beneficiation production line.

VI. Frequently Asked Questions (FAQ)

1: How do I determine if my existing gold ore ball mill needs upgrading or replacement?

A: Observe several signals: continuously increasing energy consumption per unit product; grinding fineness failing to meet process requirements and fluctuating significantly; abnormally frequent replacement of wear parts such as liners and steel balls; increased operating noise and vibration; or plans to expand production capacity. A professional equipment assessment is the first step.

2: How exactly does the new high-efficiency gold ore ball mill achieve energy saving?

A: Energy saving is mainly achieved through the integration of multiple technologies: using rolling bearings to reduce friction loss; optimizing the cylinder's length-to-diameter ratio and liner waveform to improve grinding efficiency; equipping it with a high-efficiency motor and frequency converter control to achieve "on-demand energy supply"; and lightweight design to reduce ineffective loads.

3: Are your ball mills suitable for gold mines of different sizes?

A: Yes. With 20 years of experience, we can provide a full range of gold ore ball mills, from small experimental models and medium-sized standardized models to large-scale customized models. We will recommend the most suitable model and solution based on your ore properties (hardness, mud content), target capacity, and budget.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.