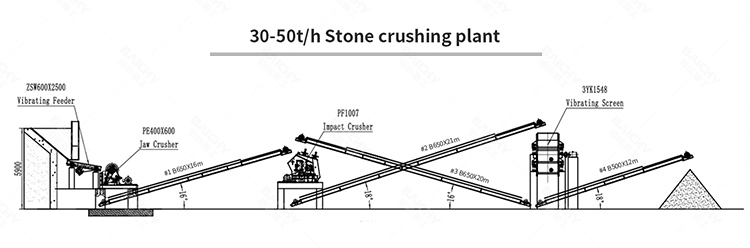

Layout diagram of a 30-50 tph feldspar crushing production line

In industries such as ceramics, glass, and chemicals, feldspar is an indispensable basic raw material, and its quality and processing cost directly affect the market competitiveness of end products. For companies planning to invest in or upgrade feldspar processing projects, a scientifically designed and stably operating crushing production line is the cornerstone of success. Among them, medium-capacity production lines with a capacity of 30-50 tons per hour (30-50 tph) are highly favored by the market due to their high return on investment and wide applicability.

With 20 years of experience in the mining crushing industry, we deeply understand the challenges our customers face in feldspar crushing: feldspar has high hardness and strong abrasiveness, posing a severe test to the wear-resistant parts of equipment; at the same time, the market has strict requirements for the purity, particle shape, and particle size distribution of feldspar powder. This article will combine our years of practical experience to provide you with an in-depth analysis of the core components and optimization points of a high-performance 30-50 tph feldspar crushing production line.

I. Core Process Analysis of a 30-50 tph Feldspar Crushing Production Line

An efficient feldspar crushing production line is not simply a collection of equipment, but an organically coordinated system engineering project. The typical process flow is as follows:

|

|

|

PE400X600 Jaw Crusher |

PF1010 Impact Crusher |

|

|

|

PYB900 Cone Crusher |

3YK1237 Vibrating Screen |

1. Feeding and Primary Crushing: Raw feldspar ore is fed evenly and continuously into the jaw crusher via a vibrating feeder. The core task of this stage is to achieve reliable primary crushing, breaking large pieces of raw feldspar ore into medium particle size. Stable feeding is the foundation for ensuring smooth subsequent processes.

2. Secondary and Fine Crushing: This is the critical stage that determines the quality of the final product. The feldspar after primary crushing enters the core equipment a high-performance feldspar crusher (usually a cone crusher or impact crusher) for further secondary and fine crushing to achieve the required output particle size.

3. Screening and Conveying: The crushed material is classified by a vibrating screen. Finished products meeting the particle size requirements are transported to the finished product stockpile by a belt conveyor; unqualified large particles are returned to the secondary and fine crushing equipment for further crushing through a return system, forming a closed-loop cycle to ensure production efficiency and yield.

II. The Heart of the Production Line: How to Choose a High-Performance Feldspar Crusher?

In production lines with a capacity of 30-50 tph, the selection of the crusher directly determines the performance, energy consumption, and long-term operating costs. Based on 20 years of technological accumulation, we recommend focusing on the following points:

• Abrasion Resistance is Paramount: Feldspar has a high silica content, causing significant wear on vulnerable parts of the equipment. Therefore, high-performance feldspar crushers must use ultra-wear-resistant alloy materials to manufacture core components (such as hammer plates and jaw walls), and optimize the machine structure to reduce wear rates and extend maintenance cycles, thereby effectively controlling operating costs.

• Application of the Laminated Crushing Principle: For hard materials like feldspar, we recommend using a hydraulic cone crusher based on the laminated crushing principle. It achieves crushing through inter-particle compression and grinding, resulting in high efficiency and a significant reduction in the generation of needle-like and flaky particles, yielding high-quality products with better particle shape and higher cubic content, meeting the demands of the high-end market.

• Stable Output Particle Size and Adjustment Capability: High-performance equipment should have convenient discharge port adjustment functions to quickly respond to different customers' needs for varying product particle sizes. The hydraulic system supports a clearing function and an iron-crossing protection function, which automatically releases upon encountering uncrushable foreign objects, effectively protecting core components and reducing unexpected downtime.

• Energy efficiency and environmental friendliness: Excellent power system design and optimized crushing chamber shape significantly reduce energy consumption per unit output while maintaining processing capacity. Simultaneously, a robust sealing structure effectively controls dust leakage, meeting increasingly stringent environmental requirements.

III. 20 Years of Experience: Beyond the Comprehensive Value Offered by the Equipment

As a manufacturer with 20 years of experience, we understand that customers are not just buying a machine or a production line, but a solution that continuously creates value. Therefore, our services extend far beyond the equipment itself:

• Personalized Solution Design: We will tailor the most economical and efficient 30-50tph production line configuration to your specific feldspar raw material characteristics (hardness, moisture content, mud content, etc.) and final product requirements.

• Full Lifecycle Support: From foundation drawings, installation guidance, and operation training to rapid spare parts supply and regular equipment health checks, we provide technical support throughout the entire equipment lifecycle to ensure the long-term stable operation of your production line.

• Maximize Return on Investment (ROI): We always prioritize our clients' return on investment, helping you gain a cost advantage in the fierce market competition by selecting more durable equipment and optimizing processes to reduce energy consumption and maintenance costs.

Investing in a 30-50 tph feldspar crushing production line is a strategic decision concerning the future development of your business. Choosing to partner with an experienced and reliable company means choosing lower overall costs, higher operational efficiency, and more sustainable investment value. With 20 years of professional experience, we are committed to becoming your most trusted partner and jointly opening a new chapter in the feldspar processing business.