Volcanic rock is a highly hard and wear-resistant rock, widely used in construction aggregates, road paving, and cement mixing. To meet customer needs—to crush volcanic rock into 10-20mm aggregates and integrate it with a cement mixing rack—we offer an efficient and flexible small mobile crushing production line solution, ensuring precise particle size control and stable production. Core Equipment Configuration of the Production Line

1. Mobile Jaw Crusher (Primary Crushing)

Recommended Model: Mobile Jaw Crusher

• Feed Size: ≤500mm

• Discharge Size: ≤150mm (prepared for secondary crushing)

Advantages:

• High mobility, suitable for mines or temporary sites

• High crushing ratio, ensuring primary crushing efficiency

2. Secondary Crusher (Cone Crusher or Impact Crusher)

Customers can choose between a cone crusher or an impact crusher for fine crushing, depending on the required particle shape and production capacity:

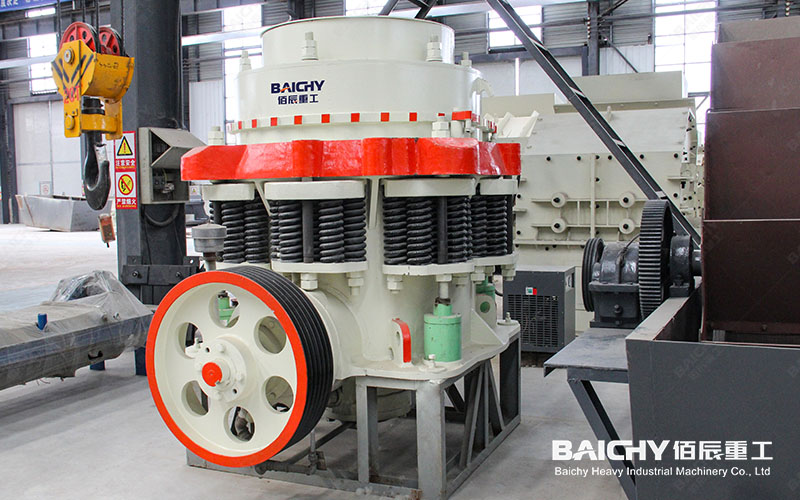

Option A: Cone Crusher (Suitable for high-hardness volcanic rock)

• Recommended Model: Baichy HP300

• Discharge Size: 10-30mm (adjustable)

Advantages:

• High wear resistance, suitable for long-term crushing of high-hardness rocks

• Good finished product shape, low flake content

Option B: Impact Crusher (suitable for medium-hard rock, better particle shape)

• Recommended model: Baichy PF1213

• Output particle size: 10-20mm (adjustable)

Advantages:

• High crushing ratio, more regular finished product shape

• Low maintenance cost, suitable for small and medium-sized production lines

3. Three-deck vibrating screen (precision classification)

Recommended model: 3YK1860 or 3YK2160

Screening specifications:

• Upper screen: 20mm (separates aggregates >20mm for secondary crushing)

• Middle screen: 10mm (separates aggregates 10-20mm)

• Bottom screen: 5mm (separates fine sand 0-5mm, suitable for sand making or cement mixing)

Advantages:

• Precise grading ensures the purity of 10-20mm aggregate.

• Can be used with a closed-circuit circulation system to improve utilization.

Suggested Design of a Cement Mixing Stand

The customer plans to use 10-20mm volcanic rock aggregate for cement mixing. A mobile concrete batching plant or a simple mixing stand is recommended. The specific options are as follows:

1. Mobile Mixing Plant (Recommended)

Equipment Components:

• Aggregate Silo (Stores 10-20mm volcanic rock aggregate)

• Cement Silo

• Screw Conveyor

• Twin-Shaft Mixer

Advantages: High degree of automation, suitable for mass production.

2. Simple Mixing Stand (Economical Option)

Structural Design:

• Steel frame + motor-driven mixing drum

• Manual feeding (10-20mm aggregate + cement + water)

• Applicable Scenario: Small projects, temporary mixing needs

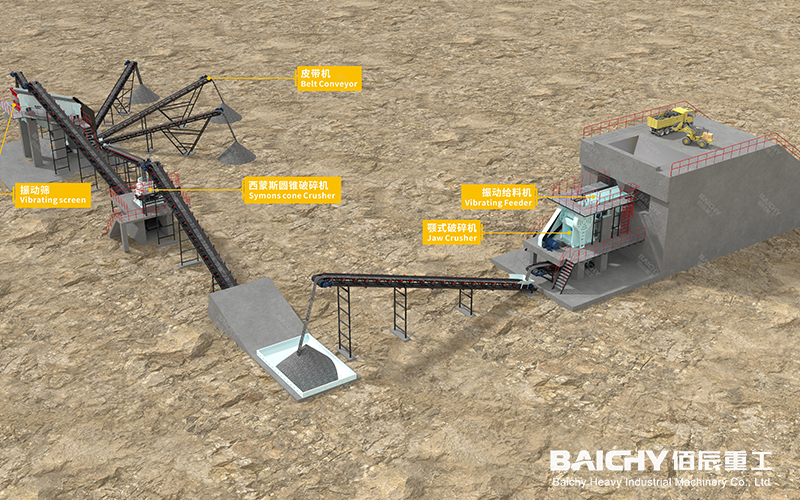

Production Line Workflow

1. Primary Crushing: Volcanic Rock Ore → Mobile Jaw Crusher (Coarse Crushing to ≤150mm)

2. Secondary Crushing → Cone Crusher/Impact Crusher (Fine Crushing to 10-20mm)

3. Screening → Three-Deck Vibrating Screen (Separates 0-5mm Sand, 5-10mm, and 10-20mm Aggregates)

4. Mixing Application → Conveys 10-20mm Aggregates to a Mixing Rack for Concrete Production

Solution Advantages

✔ High Mobility: Suitable for small and medium-sized mines or temporary sites

✔ Accurate Classification: Three-Deck Vibrating Screen Ensures High Purity of 10-20mm Aggregates

✔ Flexible Configuration: Choose between Cone Crusher and Impact Crusher to Meet Different Needs

✔ Comprehensive Support: Mixing Rack or Mixing Station Design Options Available

This 10-20mm volcanic rock crushing line combines efficiency and flexibility, making it particularly suitable for small and medium-sized aggregate production. For customized solutions or equipment selection advice, please feel free to contact us for free technical consultation!

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)