Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

PE400×600 has become the "main force" of coarse crushing in small and medium-sized mines due to its simple structure and durability. In practical applications, it is necessary to reasonably adjust parameters according to material characteristics and do preventive maintenance to maximize equipment benefits. For modern large-scale mines, it can be considered as pre-treatment equipment before secondary crushing to form an efficient linkage with subsequent equipment.

• Processing capacity: 15-60 tons/hour (depending on the hardness, humidity, and discharge port adjustment of the material).

• Maximum feed particle size: 340mm (≤320mm is recommended to ensure efficiency).

• Motor power: 30-37kW (usually equipped with a 30kW motor).

• Structural features: It adopts a simple movable jaw swing principle, the flywheel design balances the inertia force, and the high manganese steel jaw plate has strong wear resistance.

| Model | PE400x600 |

|---|---|

| Feeder Opening Size(mm) | 400x600 |

| Max. Feeding Size(mm) | 350 |

| Outlet adjusting Size(mm) | 40-90 |

| Motor Power(kw) | 30 |

| Capacity(t/h) | 15-60 |

| Overall Dimension(mm) | 1700x1750x1680 |

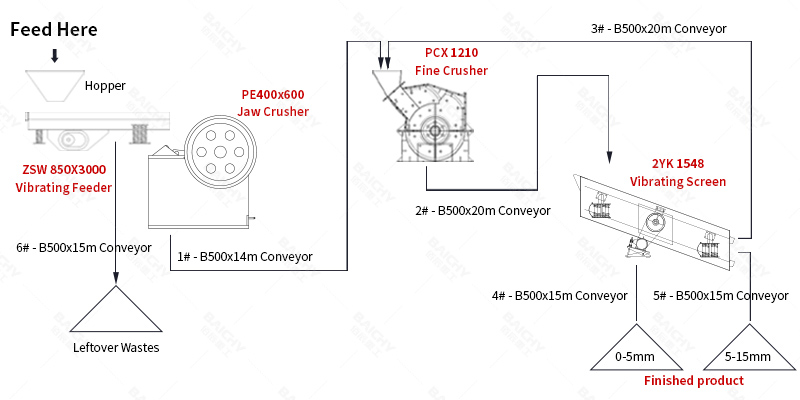

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating feeder | ZSW850x3000 | 1 |

| 3 | Jaw Crusher | PE400x600 | 1 |

| 4 | Fine Crusher | PCX1210 | 1 |

| 5 | Vibrating Screen | 2YK1548 | 1 |

| 6 | Belt conveyor | B500 | 6 |

The 40t/h crushing and screening production line is a small and medium-sized stone processing production line with a designed processing capacity of 30-50 tons per hour. It is suitable for medium-scale sand and gravel aggregate production, construction waste recycling, and primary crushing in mines and other scenarios. The equipment processes large stones (such as granite, limestone, basalt, etc.) into finished aggregates of different specifications (such as 0-5mm, 5-10mm, 10-20mm, etc.) through multiple processes such as crushing and screening.

Jaw crusher: used for coarse crushing, processing large raw materials (feed size ≤500mm), discharge size of about 100-200mm, simple structure, wear resistance.

Optional solution: If the raw material is soft (such as limestone), an impact crusher can be used instead to achieve one-time crushing and molding.

Impact crusher/cone crusher: medium and fine crushing of coarsely crushed materials.

Impact crusher: suitable for medium-hard stone, with good finished product shape and low powder content.

Cone crusher: suitable for high-hardness stone (such as granite), with strong wear resistance, but the finished product is slightly more needle-like.

Vibrating screen (2-3 layers of screen): classifies the crushed materials according to particle size, and returns unqualified materials to the crusher for reprocessing (closed-circuit system).

Feeder (vibrating feeder), belt conveyor, dust removal device (pulse bag dust removal), electronic control system, etc.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!